[Hot Focus]: Supply and demand are weak, rubber fatigue is difficult to change

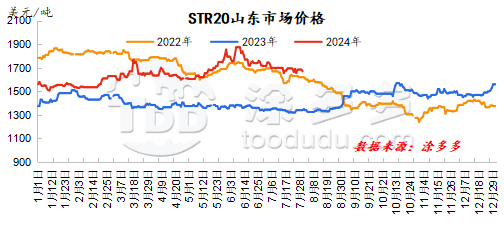

The main rubber contract officially ended the July market and began the journey in August. judging from the trend of rubber futures in July, the weak trend still maintained the main tone, and the main contract basically remained hovering around 14200, and the narrow fluctuation state was difficult to change. after entering August, the supply and demand sides are in a relatively weak state, rubber prices or continue horizontal finishing.

The main rubber contract officially ended the July market and began the journey in August. judging from the trend of rubber futures in July, the weak trend still maintained the main tone, and the main contract basically remained hovering around 14200, and the narrow fluctuation state was difficult to change. after entering August, the supply and demand sides are in a relatively weak state, rubber prices or continue horizontal finishing.

Upstream supply:Thailand's raw material prices maintain the trend of maintaining stability after falling, and Thailand's production areas have entered the period of opening and increasing production. although the rainfall weather disturbance is obvious in mid-July, the overall trend is difficult to change, and the raw material price still has a downward trend. but the overall decline was more moderate than in June, and after entering the middle of July, the typhoon weather began to strengthen, affecting the tapping work, and the output of raw materials was blocked, driving its purchase price to rise in a narrow range. Superimposed in the case of strong phenological disturbance, the raw material inventory of the processing plant is still at a low level compared with the same period last year, and then the willingness to increase prices still exists, further supporting the stability of glue prices.

The Vietnamese sidesevenIn April, the Vietnam production area entered the normal rubber cutting season, and the raw materials began to increase one after another, but the rainfall weather in Vietnam production areas this year was more than that in previous years, and there was rainfall for most of July, which affected the overall output of raw materials. Raw material prices rose in a narrow range. Since the customs adjusted the value-added tax at the beginning of this month, it has been beneficial to the demand for Vietnamese thick milk to a certain extent, but due to its color problems, the domestic downstream demand for Vietnamese gum has weakened, and the spot price of Vietnamese gum has begun to come under pressure, which has affected the profits of exports to China. Vietnam 3L factory opened better than thick milk.

Yunnan production area has entered a comprehensive cutting stage, the amount of raw materials is gradually increasing, superimposed by the end of June alternative indicators have entered one after another, the supply pressure has been gradually alleviated, and the factory production has maintained a high operating state. with the full opening of glue water, the dry rubber factory can start up to 9-10%; while the current start-up situation of the concentrated milk factory is not objective, subject to the background of the current market of thick milk, the opening of thick milk is relatively limited. However, the impact of rainfall still exists, to a certain extent, also brings support to the price of raw materials.

The weather in Hainan production area has improved obviously compared with that of last month, and raw materials have been gradually produced and released.sevenIn the first ten days of this month, the weather conditions in Hainan production areas improved, and the tapping work was gradually carried out normally. I heard that the daily rubber collection of the whole island returned to the level of about 5500-6000 tons, the glue output increased month-on-month, the purchase price of raw materials was weak, and some rubber processing plants were superimposed because of environmental protection problems. Short-term start-up is limited, raw material procurement sentiment is affected. However, after entering the last ten days, the rainy weather began to increase, the development and promotion of tapping work was hindered, coupled with the recent improvement in the demand for domestic concentrated milk, the enthusiasm of processing plants to close and start work increased, supporting the price of raw material glue began to stop falling and rebounding.

Downstream requirements:Semi-steel tire: within the month, the semi-steel tire enterprise started a high position, the snow tire production was concentrated, coupled with sufficient foreign trade orders, the device continued high-level operation, the domestic warehouse shipment performance was general, the shortage of domestic sales was alleviated, and the overall fluctuation was small.

All-steel tire: the operation rate of all-steel tire has declined narrowly this month, many enterprises have maintained a state of production control, the operation rate is weak, the shipment of domestic and foreign sales is slow, the inventory of finished products continues to be high, and some enterprises have equipment overhauled or reduced negative operation. Drag the start-up rate of all-steel tires down.

Inventory situation:Qingdao inventory continues the trend of destocking, but recently, the range of inventory removal of spot inventory has narrowed slightly. With the weakening of Tianjiao price shock, tire enterprises replenish goods at bargain prices, and there has not been a significant increase in the supply of overseas imports from the superimposed port. Qingdao total spot inventory is still dominated by a small removal of inventory.