How powerful is this pickup truck chassis?

The passability and load-bearing performance of a pickup truck mainly depends on its non-load-bearing body structure. Next, let’s talk about what is a non-load-bearing body.

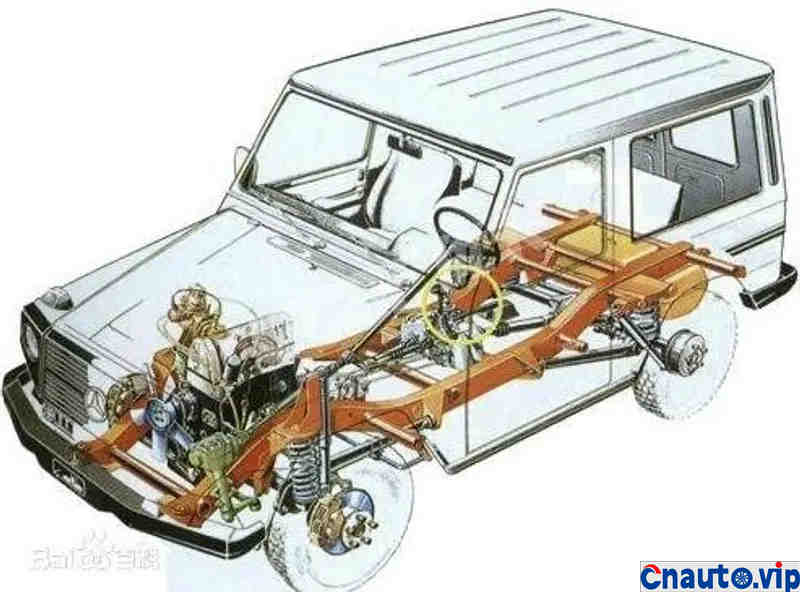

The non-load-bearing body is flexibly connected to the frame through rubber cushions or springs. The frame is the foundation that supports the entire vehicle and withstands various loads on the various assemblies installed on it. The car body only withstands the gravity and inertia force of the people and goods it carries, and the supporting role of the car body in the carriage of the car frame is taken into account when designing the car frame.

structural characteristics

It is the same as a vehicle, it is independent from the vehicle body, plays the role of a skeleton, and is made of thick steel plate welded. The chassis parts (engine, suspension, etc.) are mounted on the frame. The body made of thin plates is mounted on the frame with the help of rubber blocks.

advantages

(1) In addition to the buffering and vibration absorption effect of the tire and suspension system on the whole vehicle, the flexible rubber pad can also serve as an auxiliary buffer, properly absorb the torsional deformation of the frame and reduce noise, which not only extends the service life of the body but also improves the ride comfort and is widely used in Class IV cars and some mid-size cars.

(2) The chassis and body can be assembled separately and then assembled together, which can simplify the assembly process and facilitate the organization of professional collaboration.

(3) The frame serves as the foundation of the entire vehicle, which facilitates the installation of various assemblies and components of the automobile, and at the same time, it is easy to change the model and convert it into a vehicle for other purposes.

(4) The frame also has a certain protective effect on the body.

The chassis of the Jianghuai pickup truck adopts a trapezoidal frame with horizontal and two longitudinal axes, and the girder adopts a double lap welding process. This enhances the rigidity and stability of the chassis structure. Excellent products and processes have gone through the R & D and improvement stages. I believe everyone has heard this saying: three points are developed and seven points are trained. Jianghuai Automobile has nearly 65 years of manufacturing experience and continues to develop and manufacture excellent products.

The double yoke (double wishbone) suspension has two upper and lower yoke. The lateral force is absorbed by the two yoke arms at the same time. The pillar only carries the weight of the vehicle body, so the lateral rigidity is high. Therefore, models using this suspension have excellent roll control and strong grip during aggressive driving. In addition, their longitudinal strength is significantly lower than that of multi-links, which is more conducive to the layout of the chassis.

April 1, 2024

April 1, 2024  March 27, 2024

March 27, 2024

March 27, 2024

March 27, 2024