Shurnov sound insulation modification/Beijing Spade K car sound insulation modification/Honda Fit sound insulation modification

In the process of using the car recently, the owner found that the engine noise in the Honda flying car is more obvious, and the incoming wind noise and tire noise are becoming more and more serious. I have been to the 4S store for a detailed inspection, but it has not solved the noise problem in the car very well. In order to get rid of the noise problem as soon as possible, the car owner decided to change the sound material of another brand and came to Beijing spade K to upgrade the sound insulation.

Tian Fei took a group photo with soundproof material

Honda flying sound insulation configuration list:

Shop owner: Beijing spades K

Bonnet: SU200 shock absorber + ST-Y hood special cotton

U-shaped slot: SU200 shock absorber + SR150 high elastic cotton

Four doors sound insulation: SU200 shock absorber + SR100 white cotton

Chassis + trunk + rear hub: SU200 shock absorber + SR100 white cotton

Front wheel arc: SU200 shock absorber + SO450T sound insulation pad + SR100 white cotton

Leaf board: SU200 degumming + SR100 white cotton

The noise of the engine cabin is the main source of the sound of the vehicle itself. In order to solve this problem, it is mainly from the engine and U-shaped slot. The modification makes Shuernoff’s SU200 glue reducer and ST-Y engine special cotton double-layer sound insulation treatment of the hood, which can effectively reduce noise transmission and slow down the heat quantification and corrosion of the engine room affected by the hood. Then the U-shaped slot is treated with SU200 shock absorber and SR150 high elastic cotton.

The bonnet first uses SU200 shock absorber for the first sound treatment to reduce the resonance produced by the engine into the car, and then uses ST-Y bonnet special cotton to isolate the heat.

Sound insulation of U-shaped grooves with SU200 shock absorber and SR150 high elastic cotton

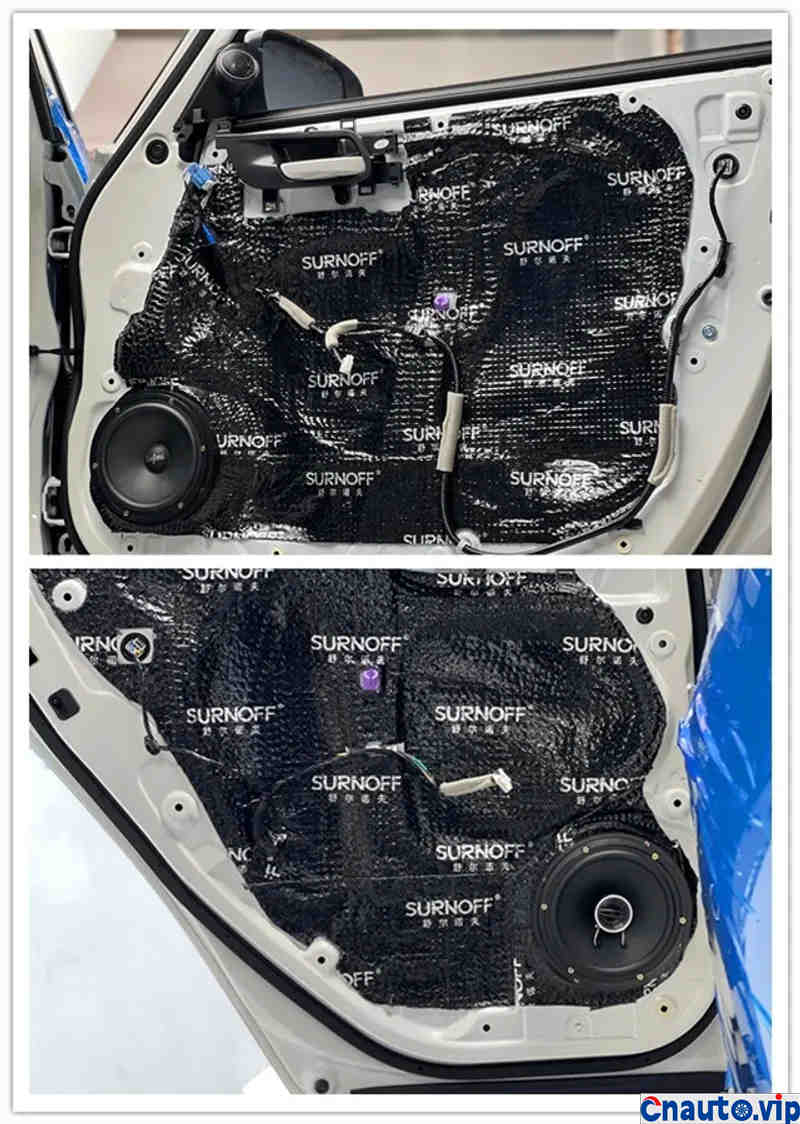

Because there is only a simple plastic film inside the original door panel, it is difficult to have a good sound insulation effect, so the refit division gently tore off the plastic film of the original door panel, and then used SU200 shock absorber + SR100 white cotton to do three layers of sound insulation treatment on the door panel, thus reducing the introduction of wind noise.

The front and rear door panels make SU200 shock absorber double-layer sound insulation treatment.

The removed door panel cover is then treated with SR100 white cotton for the third layer of sound insulation, which can filter the remaining noise.

The sound insulation of the original chassis is poor, and the chassis is the place where the road noise is most easily introduced, and the noise generated by the exhaust pipe is introduced into the car through the chassis to form a resonant sound pressure. The tail box is the main channel of rear hub noise and exhaust pipe noise, through the tail box will introduce a lot of noise and dry heat. So the retrofit engineer uses SU200 shock absorber and SR100 white cotton to treat the bottom, tail and wheel separately to build a noise barrier for the car!

Chassis and tail box use SU200 shock absorber for the first layer sound

The chassis and trunk use SR100 white cotton for the second layer of sound insulation.

The rear hub is also treated with double layer sound insulation.

In order to further enhance the effect of sound insulation and vibration reduction, the retrofit engineer uses Shuernoff SU200 shock absorber + SO450T sound insulation pad + SR100 white cotton to do three layers of sound insulation for the wheel arc. In addition, the leaf board is specially removed and cleaned, and the leaf board is treated with SU200 shock absorber + SR100 white cotton, so as to reduce the impact of flying stones, reduce the friction sound between tire and surface, and cut off the transmission way of noise.

The wheel arc is full and compacted with Shuernov sound material, which has a long service life and is easy to take off.

The leaf board is treated with SU200 damping glue and SR100 white cotton for sound insulation.

System comments:

Although the workload of the soundproof modification is relatively large, the modification was completed in the shortest possible time with the very skilled technology of the retrofit division. After a long test drive, the owner said that the car had obviously become quiet and had a sense of “isolation” in the car, and praised the upgrade.

Recommended Suppliers

April 1, 2024

April 1, 2024

March 27, 2024

March 27, 2024  March 27, 2024

March 27, 2024