The diy Buick Sail replaced the rear axle bushing. The bushing had been bought for a long time. Recently, there were 5 people sitting on the car, and the chassis made a clackling sound, so I started replacing it.

Here’s a reminder: First of all, we must predict the occurrence of relevant dangers and do a good job in personal and vehicle safety. The picture above

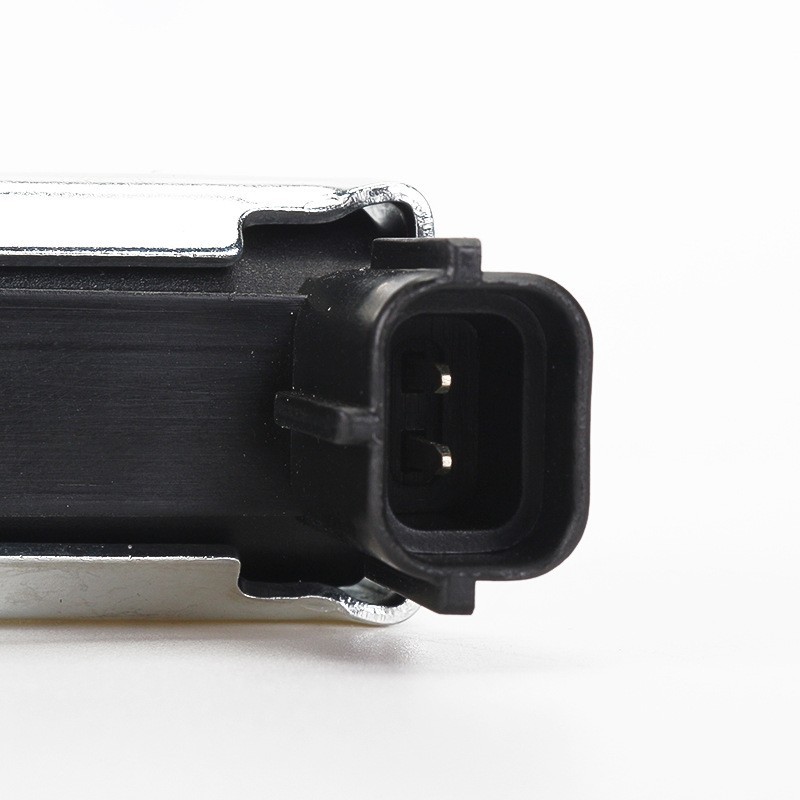

The outer diameter size of the bushing is 59mm, and the middle hole is 10mm. The model after 2003 seems to be 12mm

The front and rear of the front wheels should be held up with bricks, because when the rear axle is lowered, the vehicle will move forward to avoid accidents and safety comes first.

Use strong wooden blocks to lift the car to avoid swinging. Use a brick on both wheels,

Lower the rear bridge

Tie the spring tightly with iron wire to make it easier to operate, and loosen the rear damping nut

Loosen one end of the brake oil pipe, wrap it with an 8mm screw and block it

Use bricks to cushion

After putting down the rear bridge

Tie the spring

Loosen the bushing. Because the casing of this bushing is made of plastic rather than metal, it is easy to loosen. Method: Knock it directly with a hammer head, without using very hard force. After a few hits, it will become loose. Then use a steel pipe to withstand the knock. It will come out in a few seconds and no need to use an extrusion tool.

Spray it with a cleaning agent a few times to lubricate it, use a steel pipe to knock it a few times, and it comes out

after coming out

Clean surfaces with detergents

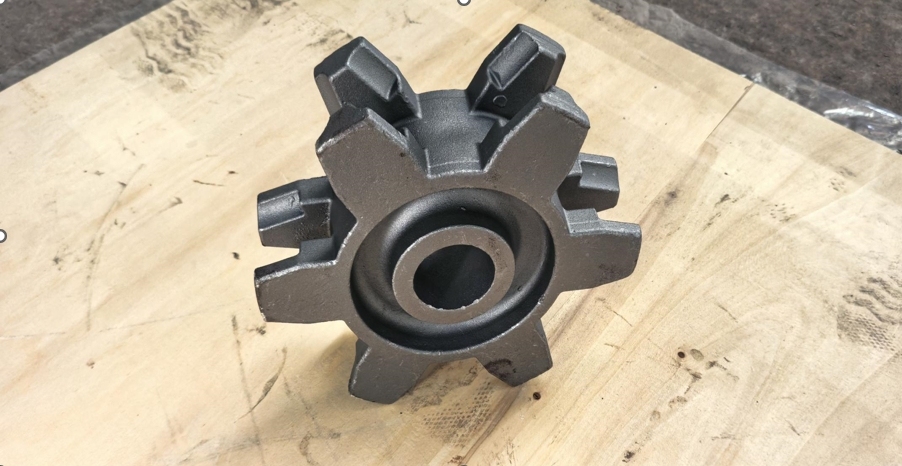

Compared with the old and the new, the old one is obviously broken

The press-in tool purchased online, a bolt with a length of 20cm and a reinforced hardness of 8.8, and an extension nut, a steel sleeve with an inner diameter of 60mm, two large planar mesons with an outer diameter of 66mm and an inner diameter of 25mm, and a planar pressure bearing with an inner diameter of 10mm, totaling tens of meters

Apply oil to the bushing surface to enhance lubrication

Set one side

pressed in

Press slowly in

Mark well to ensure that it is consistent with the position before disassembly

Mark well to ensure that it is consistent with the position before disassembly

After pressing it, use a jack to lift it up and restore it. Tighten the nut with a force of 50 Nm, and use the nut for the rear shock absorber to restore the brake oil pipe. Then exhaust the air from the brake oil pipe, remove the steel wire binding the spring, and complete the project.

April 1, 2024

April 1, 2024