[recovery] observation on the routine maintenance of car 4S in the changing season in spring

Friends who have worked in the enterprise manufacturing department or production workshop have such experience that at the turn of the season, regardless of equipment, machine tools or instruments, the failure rate of the electrical or mechanical part will be significantly higher than that of other periods. Automobile is a complex complex which integrates mechanical and electrical systems, and it also has such phenomena and laws. Traditional Chinese medicine has the theory of spring noise, which means that the balance of yin and yang in the body needs to be adjusted in spring, and the car is in fact the same. The current spring season is the time of change of season, so car care and maintenance should be paid attention to, timely maintenance and proper conditioning. it plays a positive and beneficial role in the health and performance of the vehicle.

My family car is a Dongfeng Citroen C5 hand-integrated 2.3-liter luxury car, the car has been basically maintained in 4S stores for more than a decade, and the accessories are all authentic from the original factory. Carefully observed the working process of technicians in 4S shop, compared with the environmental facilities of 4S workshop as well as the technical level and professional accomplishment of technicians. This spring maintenance is slightly ahead of the normal maintenance cycle calculated by time and mileage, first because of the changing seasons in winter and spring, and second, because of the replacement of tires, batteries, front bearings, brake pads, gasoline pumps, CVVT wheels and other spare parts last year, I want to know the condition and condition of the car more directly. During maintenance, I did not wait for tea on the sofa in the customer lounge as usual, but chose to observe the whole process at the maintenance site and communicate with the technician. There are a few links worth talking about:

Environmental facilities of Dongfeng Citroen 4S workshop

Waiting for maintenance

The operation flow of the 4S technician is relatively standardized, and adding the steering wheel cover, the main driver seat protection cover and the engine room outer protection pad is the first step of the standard procedure. Just like the door-to-door service of home appliance customer service personnel, putting on their own shoe covers when entering the door is a heart-warming little move.

Before changing the oil, add an engine cleaner to the oil tank, start the car to idle for about 10 minutes for internal circulation cleaning, then use the pumping unit to pump out the old oil, and then unscrew the oil pan screw to release the remaining oil. In this way, compared with directly unscrewing the screw to release oil, the oil tank and the internal lubrication system of the engine should be cleaned more thoroughly.

Adding the steering wheel cover, the main driver seat cover and the outer protective pad of the engine room is the first step of the standard procedure.

Take out the maintenance consumables.

5W-40 fully synthetic engine oil. It is recommended that Dongxue launch a 4.5-liter package to avoid having to add a big and a small barrel of oil each time.

Engine cleaner, engine protectant, oil filter.

Use a pumping unit to pump out old oil

The suction of this kind of pumping unit is very large, and the obvious sound of air flow can be heard when it is almost empty.

Unscrew the oil pan screw to release the remaining oil.

Clean the old oil so that the oil tank is clean.

Install a new oil filter.

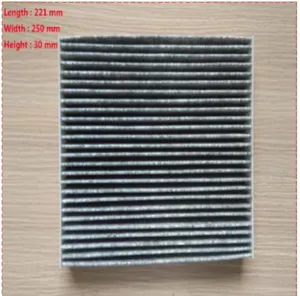

Oil filter

Do not add the new oil until the above process is completed.

As the tire has been renovated for half a year, specially told technicians to pay attention to observe the tire condition, the best flying boots for a long time ride the second generation is an attempt, the effect still needs to be tested in practice. Careful observation of the tread shows that the wear is so slight and uniform that even the process marks of tire pressing can still be identified. Tread pattern groove edges and corners are flat and sharp, there is no patch peeling off, indicating that the carcass material is dense and delicate. The side of the tire has been slightly scraped, and the fetal hair is still intact and firm, which also shows that the rubber has excellent elasticity and toughness. Conventional maintenance only makes a dynamic balance to the two front tires, and the rear wheel is not included in the conventional content, which is slightly inadequate.

Careful observation of the tread shows that the wear is very slight and uniform.

Tread pattern groove edges and corners are flat and sharp, there is no patch peeling off, indicating that the carcass material is dense and delicate.

The process marks of tire pressing are still debatable.

The friction plates that were replaced last year usually step on the brakes relatively softly, so it seems that the disc and the plate are in good condition.

The battery on the car was newly replaced in October last year and has been used for only 4 months before maintenance. The battery is marked as CCA700A, and the actual test value of this maintenance is 500A, which belongs to the normal range. However, the technician thinks that the attenuation speed is a little too fast, and it is generally believed that the normal use of the vehicle will be affected when the battery charge is less than 300A. He asked about the normal use of the vehicle and suggested running more long distances to keep the battery full, which is conducive to prolonging the service life of the battery.

The newly replaced battery has been used for 4 months.

Battery detection

Measured data CCA500A

There are a few small details handled well. For example, because of the low chassis of the vehicle, the rear fender often scrapes the pipe on the ground when reversing into the parking space, and the ears of the rear wheel plastic fender are pulled away from the fixed screws. this is an old problem. This time, the master did not simply reset and tighten the screws, but specially found a large and thin gasket to fix the tension gap, so that it would not fall off easily. If you find that the wiper water pressure is small, first do not consider the motor problem, but use the blow gun to clean the pipe, and then try OK, it turns out that the water pipe is a little blocked, so as to avoid some unnecessary maintenance and replacement. And after the completion of the cabin cleaning, not simply blowing dust, but with foam cleaning agent for cleaning, the effect takes on a new look.

A large and thin gasket is specially found to fix the tension gap.

Blow the wiper water line with a blow gun.

Clean the engine compartment with foam cleaner.

After cleaning, the engine compartment has taken on a new look.

Mutual inspection of maintenance operations is a very good process link, you can often find some problems that you have ignored or omitted, such as your own draft articles to be proofread by others, you can often find that you have not proofread the corrigendum. This program has not gone through the formalities today, and the fat master next to it is still watching it very seriously!

Mutual inspection is carried out by the fat brother master in the next station.

Look at the master almost done, want to save some time, went to the front desk to check out payment, did not expect to be declined by the customer service, because the technician has not yet received the completion report form, turned to look at the workplace technician is buried in the filling, it seems that 4S customer service staff process awareness is very rigorous in place.

The technician fills out the completion report.

Finish the maintenance work and wait for the car wash.

In fact, these processes and links are commonplace and common in many standardized manufacturing departments or production workshops of enterprises. They are all part of institutionalized operation instructions and operating specifications. Although the time for completing the operation process will be extended, they are effectively improved. Operation quality and service quality.

Regarding 4S maintenance services, riders ‘evaluations also vary. Although 4S has advantages in terms of standardized processes, complete facilities, sufficient spare parts, and reliable skills, it also has high component costs and service costs. How to choose and choose should not be generalized. Specific issues need to be analyzed in detail. Just choose what suits you.

Thanks for reading!

April 1, 2024

April 1, 2024  March 27, 2024

March 27, 2024

March 27, 2024

March 27, 2024