DIY-Buick Sail oil pressure indicator flashing fault repair

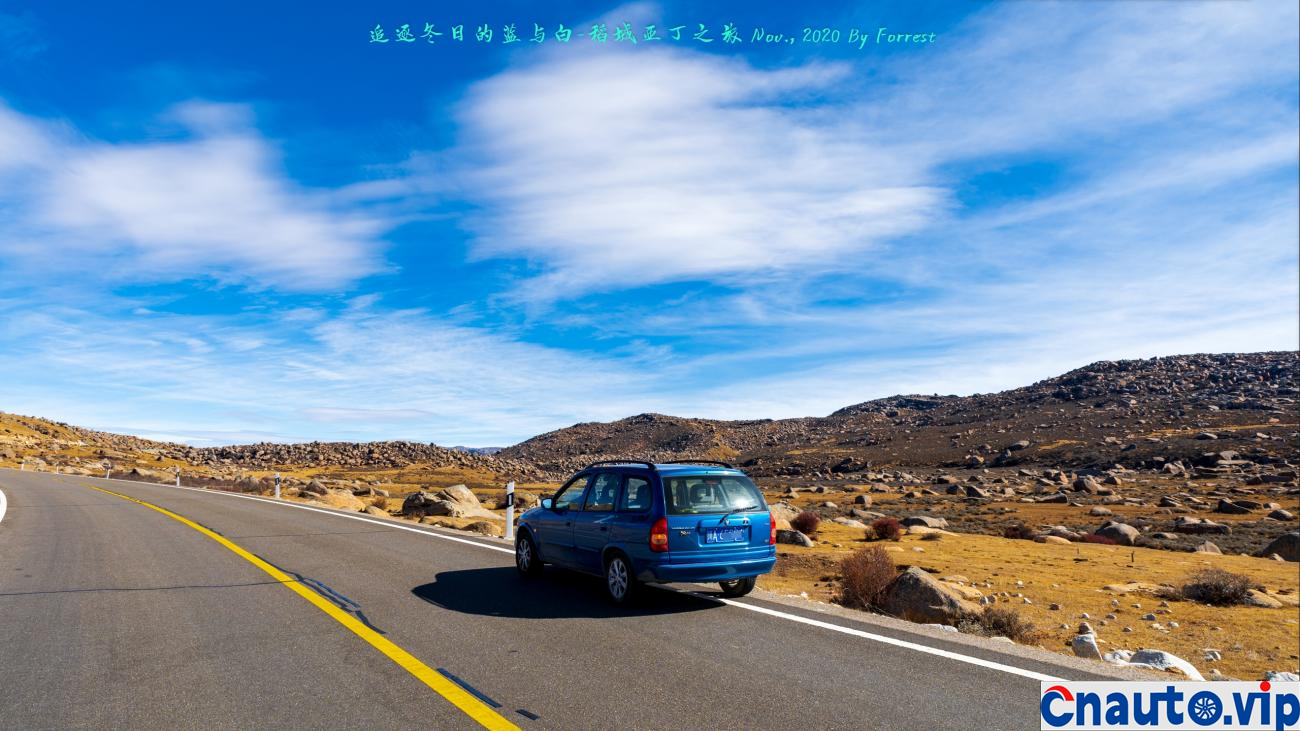

In a trance, this Sail has been with me for 18 years. I replaced almost every part of him by myself, and he was in good condition. He could travel one or two thousand kilometers in western Sichuan by bike. Recently, during the state celebration of the 70th anniversary of Ganzi Prefecture, the scenic spot was free of admission. I also found a reason to brush the rice city Aden, which I passed through Litang for N times. I took a taxi back and forth on the 3rd, traveled 800 kilometers a day, and ran at night in winter, filling in the gap of night walking at high altitude in western Sichuan in winter.

Back from the rice city of Aden, on Haizi Mountain 4300 meters above sea level.

Fortunately, it went smoothly, but swayed a few times on a section of icy road. But in Aden, it was found that the ignition switch was in the III gear, sometimes the oil pressure lamp flickered on and off, sometimes it didn’t even turn on (normally it was always on), but it didn’t light up after ignition. Immediately check, discharge oil pressure is insufficient, this is a “fatal” thing, open the oil filling cap, oil spatter, the engine is also working normally, it seems that the oil pressure is normal, it should be the oil pressure switch or circuit problem.

This fault has also occurred before. When the oil pressure switch is removed, it is found that there is a lot of mud in the detection hole and there are dozens of resistances. it is thought that the pressure of the diaphragm is caused by the blockage of the oil and the contact is not good. After cleaning and installation, it works normally.

After coming back to confirm that there is still a fault, first discharge the wire harness fault, disconnect the oil pressure switch plug from the ignition coil, the measuring voltage is 12V, the wire harness should be no problem, basically make sure that the pressure switch is dead.

Order the oil pressure switch immediately and the goods will arrive soon. This DIY did not go to the repair shop of acquaintances, and the ground support construction was used in the community. The construction of ground support should pay high attention to safety. I use the standard support frame, the load-bearing 3T support frame is used on both sides, the ground must be solid and flat, and the rear wheel is fixed with tire plug. You’d better put on a spare tire to prevent an accident.

This fault has also occurred before. When the oil pressure switch is removed, it is found that there is a lot of mud in the detection hole and there are dozens of resistances. it is thought that the pressure of the diaphragm is caused by the blockage of the oil and the contact is not good. After cleaning and installation, it works normally.

After coming back to confirm that there is still a fault, first discharge the wire harness fault, disconnect the oil pressure switch plug from the ignition coil, the measuring voltage is 12V, the wire harness should be no problem, basically make sure that the pressure switch is dead.

Order the oil pressure switch immediately and the goods will arrive soon. This DIY did not go to the repair shop of acquaintances, and the ground support construction was used in the community. The construction of ground support should pay high attention to safety. I use the standard support frame, the load-bearing 3T support frame is used on both sides, the ground must be solid and flat, and the rear wheel is fixed with tire plug. You’d better put on a spare tire to prevent an accident.

This is a picture of the previous ground support construction.

The oil pressure switch is easy to change, located at the back end of the engine near the water pump, next to the crankshaft position sensor, and can be disassembled with an extended sleeve of 24mm. The installation torque 30Nm, which I installed with a torque wrench, fully complies with the maintenance specification.

The brown one in the picture is the oil pressure switch.

After installation and inspection, turn the ignition switch to the III position, the oil pressure light is very red, and the ignition goes out, which is completely normal.

It’s over.

It’s over.

Supplementary information:

1. About Buick Saio oil pressure sensor purchase.

The model of the original car is 93352638. It looks like it is imported, but it is not available in the domestic market. The Buick parts catalog gives the accessory number 93306126, thread specification M14 # 1.5, and trigger pressure 30KPa-55KPa. But this model is not easy to buy, can buy is 9031389, Buick accessories catalog shows that the Kay Yue 1.6L79 engine, the appearance, thread is exactly the same, but the trigger pressure is 22KPa7KPa. But the seller said it was Kaiyue and Saio GM. The oil pressure parameters are relatively loose and should be available for use.

2. Cut the pressure switch of the original car removed, the structure is very simple, that is, a diaphragm + plus a metal sheet and a spring, the oil pressure is applied on the diaphragm to open the metal sheet, the switch is broken, and the indicator is turned off, otherwise it is lit. Using my Makita brushless angle grinder, cutting is easy.

1. About Buick Saio oil pressure sensor purchase.

The model of the original car is 93352638. It looks like it is imported, but it is not available in the domestic market. The Buick parts catalog gives the accessory number 93306126, thread specification M14 # 1.5, and trigger pressure 30KPa-55KPa. But this model is not easy to buy, can buy is 9031389, Buick accessories catalog shows that the Kay Yue 1.6L79 engine, the appearance, thread is exactly the same, but the trigger pressure is 22KPa7KPa. But the seller said it was Kaiyue and Saio GM. The oil pressure parameters are relatively loose and should be available for use.

2. Cut the pressure switch of the original car removed, the structure is very simple, that is, a diaphragm + plus a metal sheet and a spring, the oil pressure is applied on the diaphragm to open the metal sheet, the switch is broken, and the indicator is turned off, otherwise it is lit. Using my Makita brushless angle grinder, cutting is easy.

Hot Information

Tesla Autopilot and similar automated driving systems get ‘poor’ rating from prominent safety group

April 1, 2024

April 1, 2024 Localization of EV parts without production scalability may not help cut EV price, says President, Amara Raja

March 27, 2024

March 27, 2024

JCTSL may turn bus stands into charging points for e-buses

March 27, 2024

March 27, 2024 You May Like