Notes on butter application of eight positioning bolts in Pajero V97

After purchasing the Bobcat V97 (Middle East version) in January 2019, I have traveled several long-distance self-driving tours in the past two years, with a total mileage of 50,000 kilometers. After joining the WeChat group of the “Ica Pajero Forum”, the heroes in the group discussed the topic of oiling the positioning bolts, saying that these eight positioning bolts are easy to rust, especially after wading through water; after rusting, they cannot be twisted and can only be cut. This is a nuisance.

Taking advantage of 50,000 kilometers for maintenance, I requested to add the project of greasing these 8 bolts. The sales consultant of the 4S shop that received me saw my firm request, so he called the maintenance master to discuss it. The maintenance master said it was okay, but it was troublesome. Should we only butter the back four bolts? The first four are fine. I say put on all eight pills in one trip.

At 9 a.m., Bobcat entered the workshop, and I asked to study and observe on the spot. Normally, customers were not allowed to enter the workshop of the 4S shop, but at my strong request, they agreed, but repeatedly warned them about safety precautions. I understand this very well and abide by the regulations. In Hong Kong, after a vehicle is lifted up, if a customer rashly stands under the vehicle and watches, and if the lifting frame fails and falls instantly, it will hurt people.

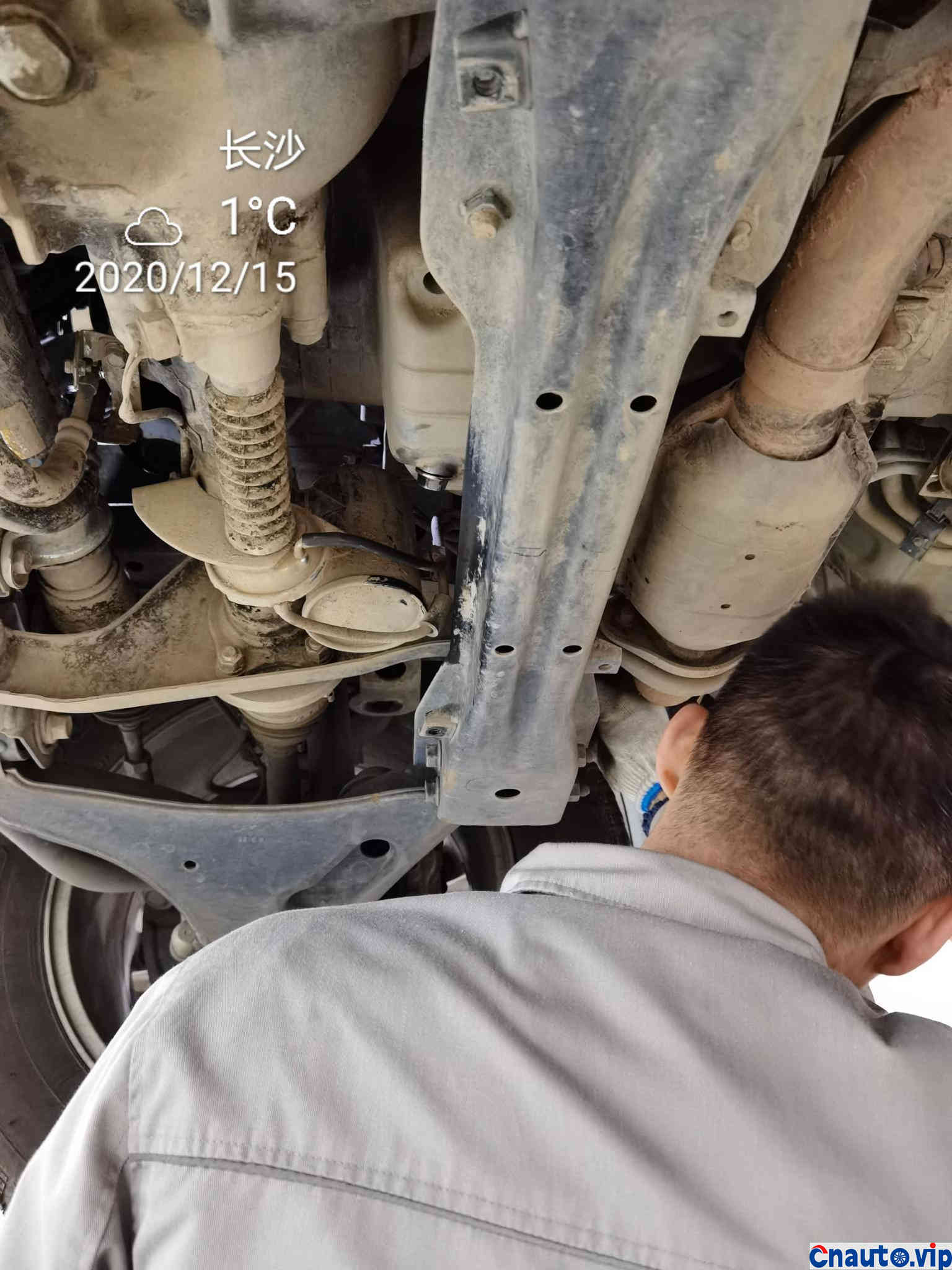

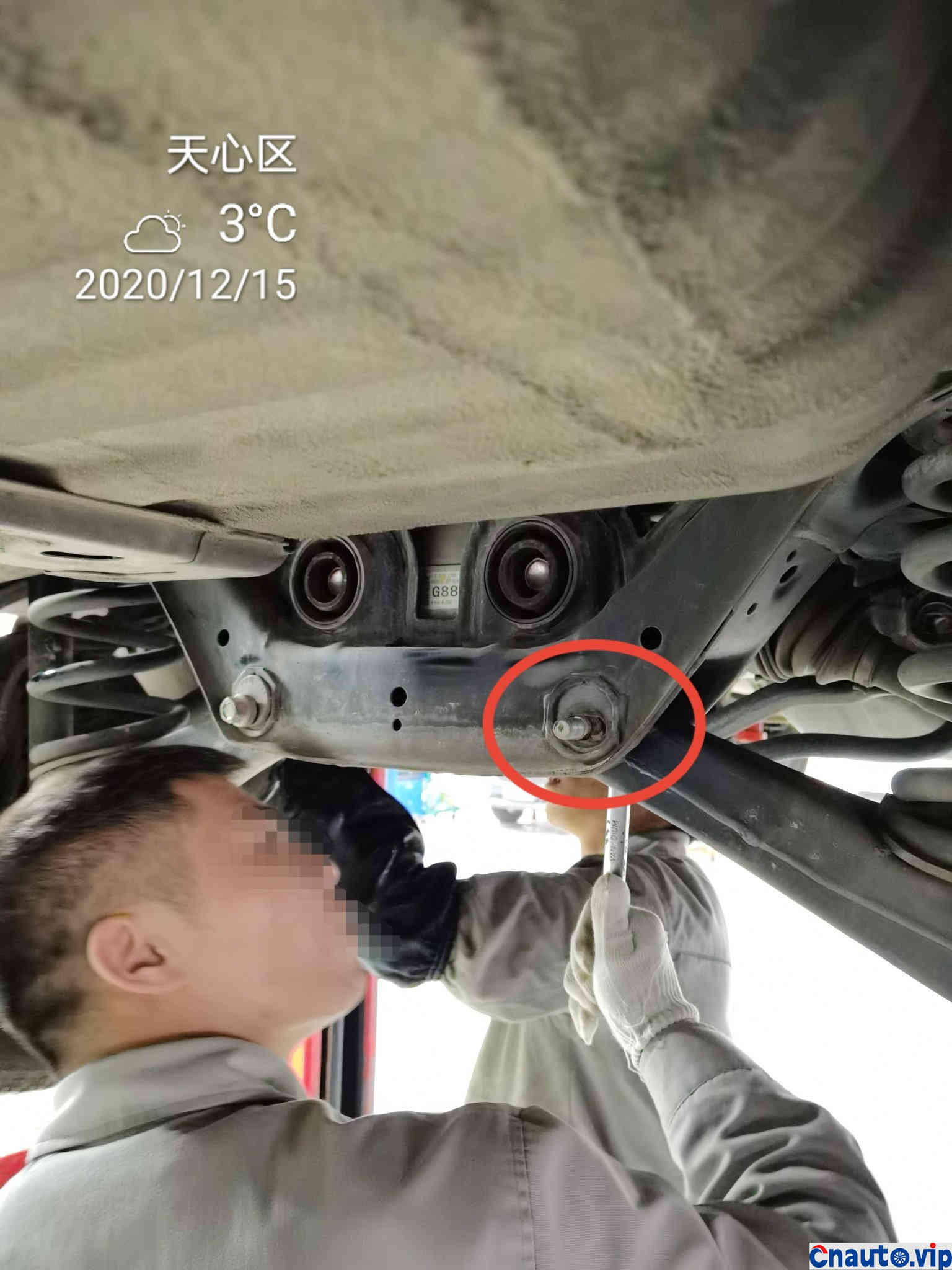

Routine maintenance is simple and takes tens of minutes to complete. It is easy to remove the eight positioning bolts. After butter the screws and the “holes” to pass through, it is a bit difficult for the screws to pass through the “holes”, and the “holes” are difficult to overlap. The master moved a jack more than one meter high and adjusted it with a metal rod here. Another master threaded the screw in the opposite direction and hammered it with it. Finally, he threaded it “savagely” and screwed on the nut. OK. It actually took nearly two hours to get these 8 bolts ready.

Grease the 8 positioning bolts after installation and reset, four-wheel positioning must be done. Although troublesome, it was worth it.

The master said that if you apply butter this time and drive another 50,000 kilometers, the bolts should not rust to death. I said that’s okay, and I’ll come back to apply oil then.

Taking advantage of 50,000 kilometers for maintenance, I requested to add the project of greasing these 8 bolts. The sales consultant of the 4S shop that received me saw my firm request, so he called the maintenance master to discuss it. The maintenance master said it was okay, but it was troublesome. Should we only butter the back four bolts? The first four are fine. I say put on all eight pills in one trip.

At 9 a.m., Bobcat entered the workshop, and I asked to study and observe on the spot. Normally, customers were not allowed to enter the workshop of the 4S shop, but at my strong request, they agreed, but repeatedly warned them about safety precautions. I understand this very well and abide by the regulations. In Hong Kong, after a vehicle is lifted up, if a customer rashly stands under the vehicle and watches, and if the lifting frame fails and falls instantly, it will hurt people.

Routine maintenance is simple and takes tens of minutes to complete. It is easy to remove the eight positioning bolts. After butter the screws and the “holes” to pass through, it is a bit difficult for the screws to pass through the “holes”, and the “holes” are difficult to overlap. The master moved a jack more than one meter high and adjusted it with a metal rod here. Another master threaded the screw in the opposite direction and hammered it with it. Finally, he threaded it “savagely” and screwed on the nut. OK. It actually took nearly two hours to get these 8 bolts ready.

Grease the 8 positioning bolts after installation and reset, four-wheel positioning must be done. Although troublesome, it was worth it.

The master said that if you apply butter this time and drive another 50,000 kilometers, the bolts should not rust to death. I said that’s okay, and I’ll come back to apply oil then.

Enter the workshop at 9:00 and do routine maintenance first. The main thing is to change oil. Please ask the master to remove the air filter element and air conditioner filter element and blow it off with an air gun before installing it. This time, I didn’t replace it with a new one.

Four rounds of transposition without dynamic balance.

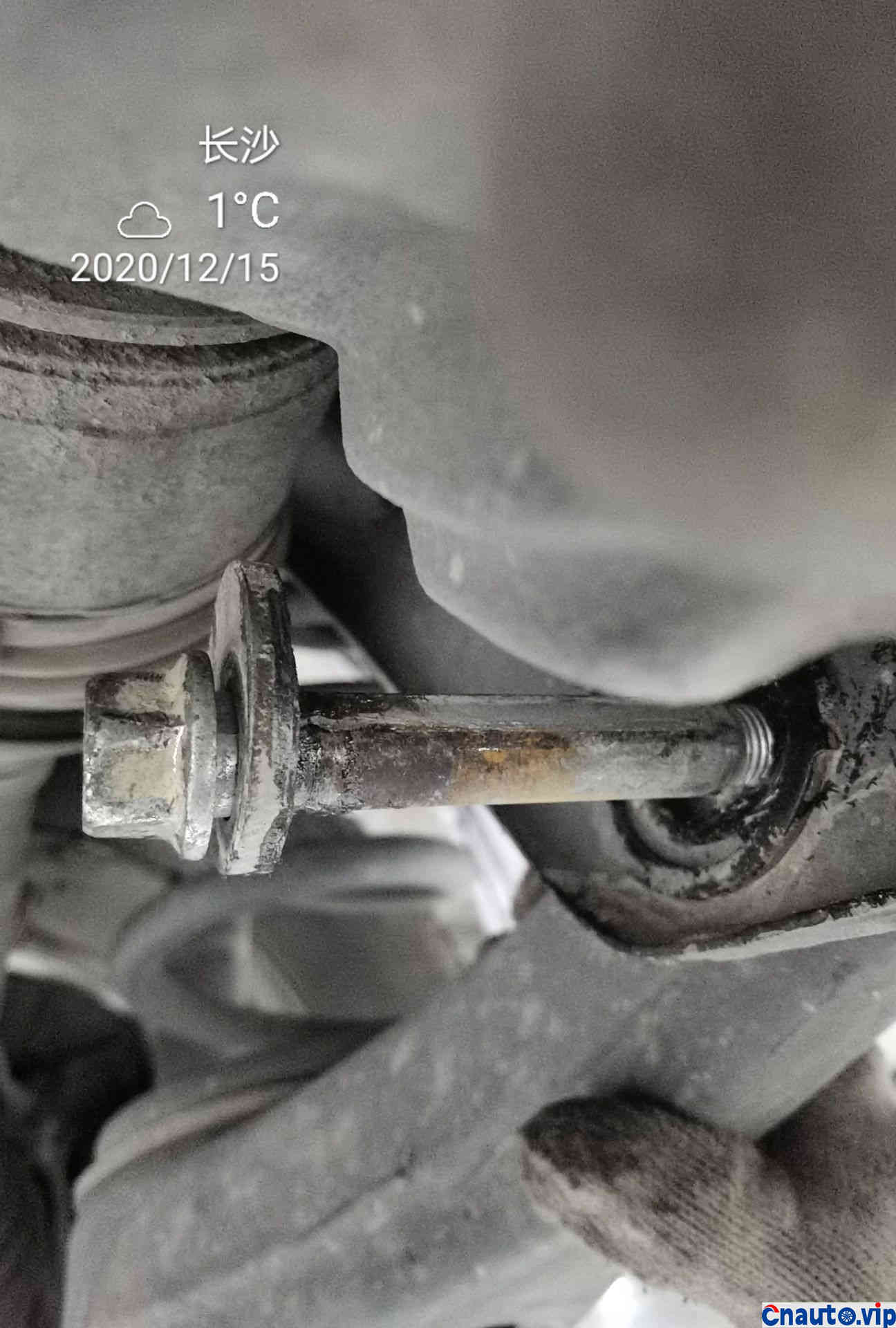

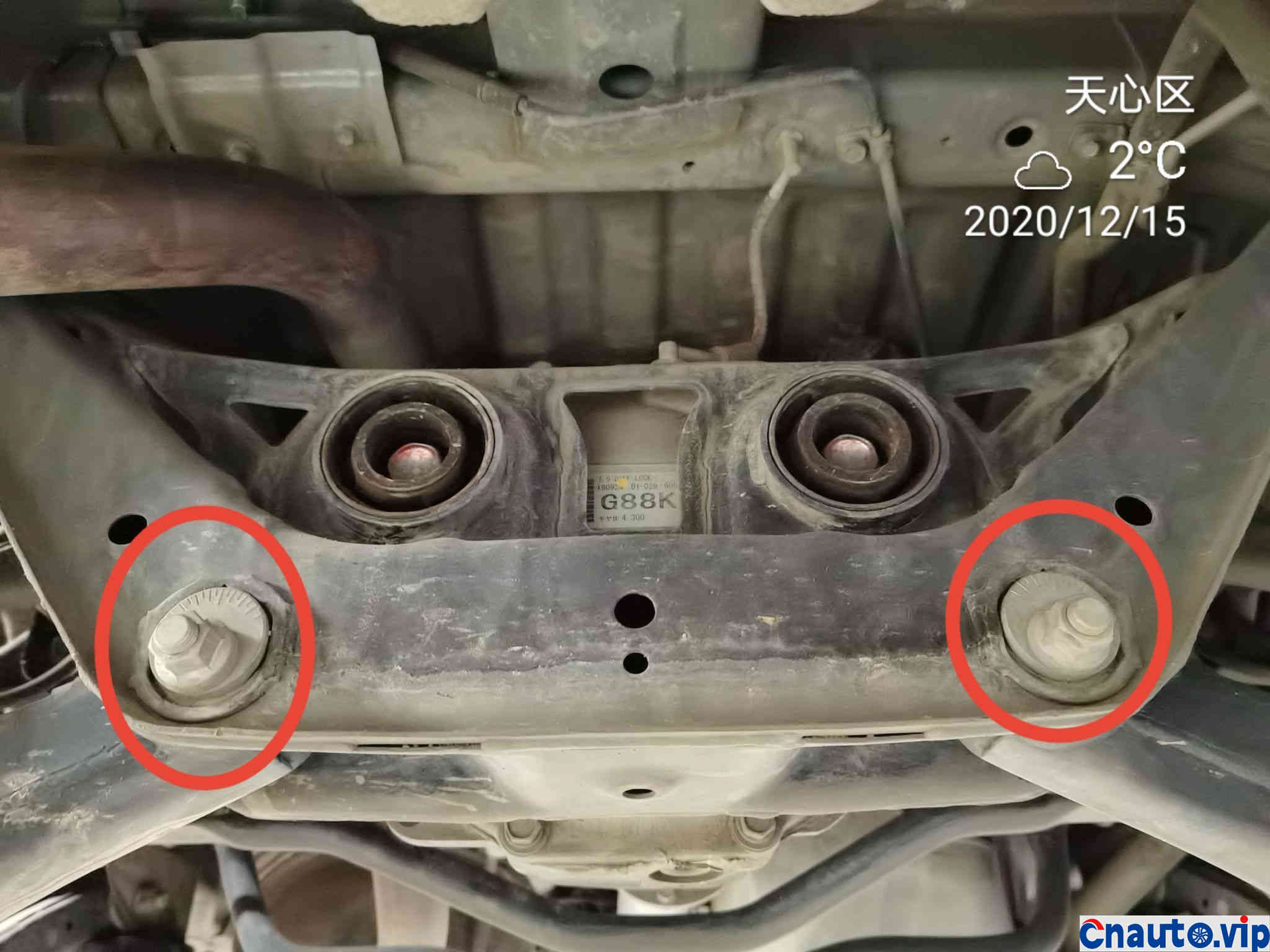

The bolt at the back is rusty.

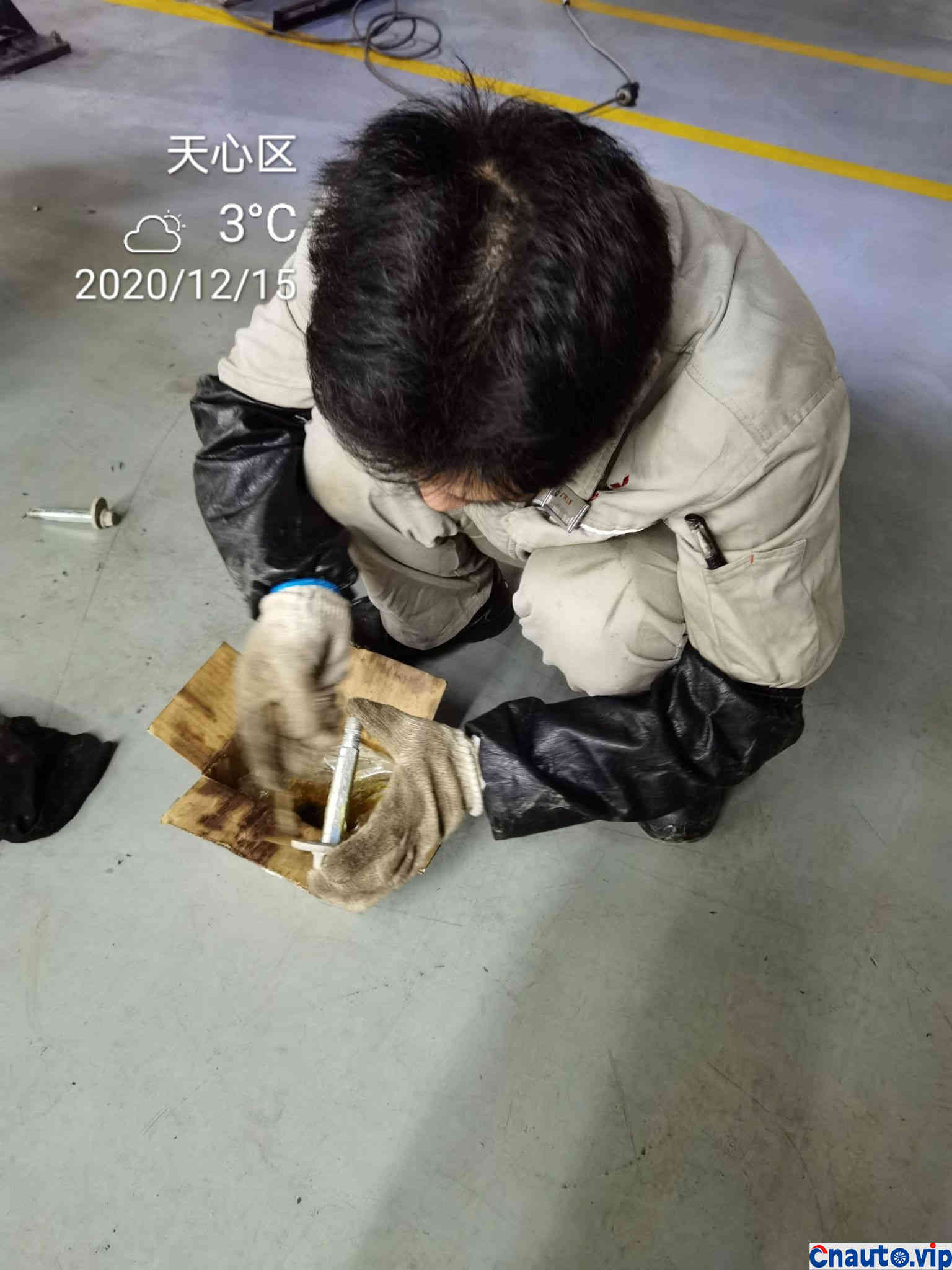

This is the time to butter.

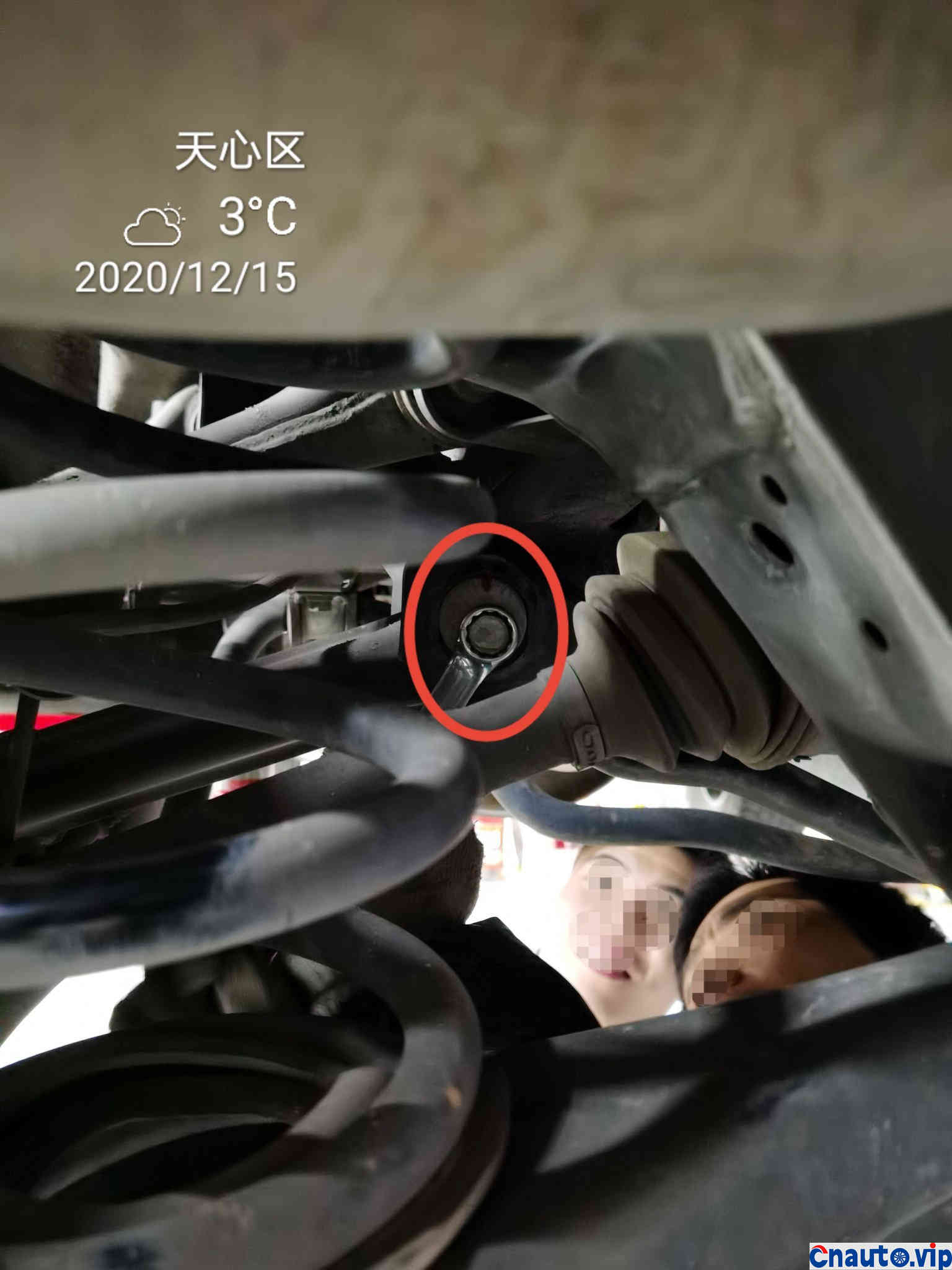

Loose bolts are easy.

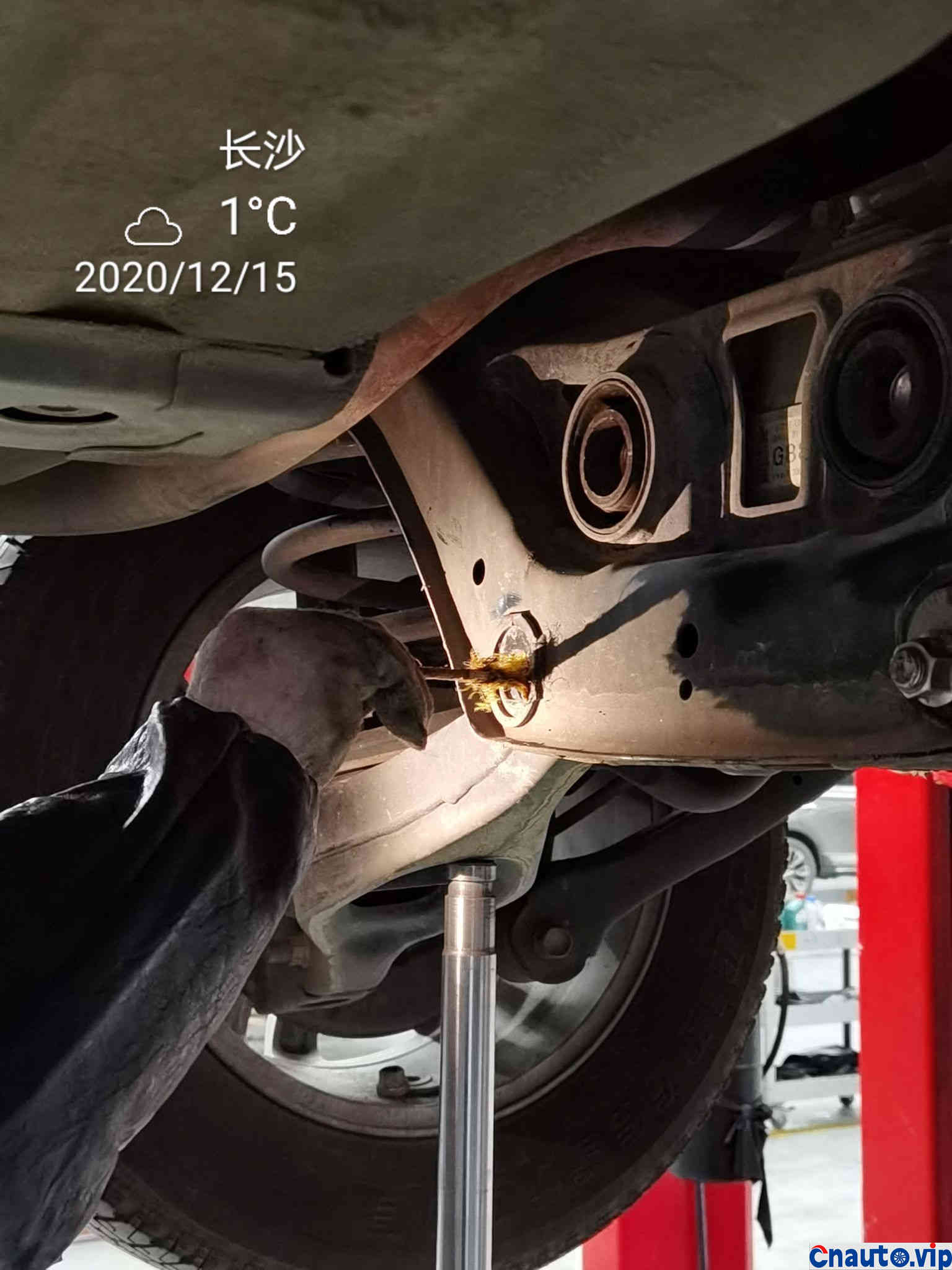

It’s a bit troublesome to install the bolts. Use a one-meter-long gold top to support them, which is a good eye-catching sight.

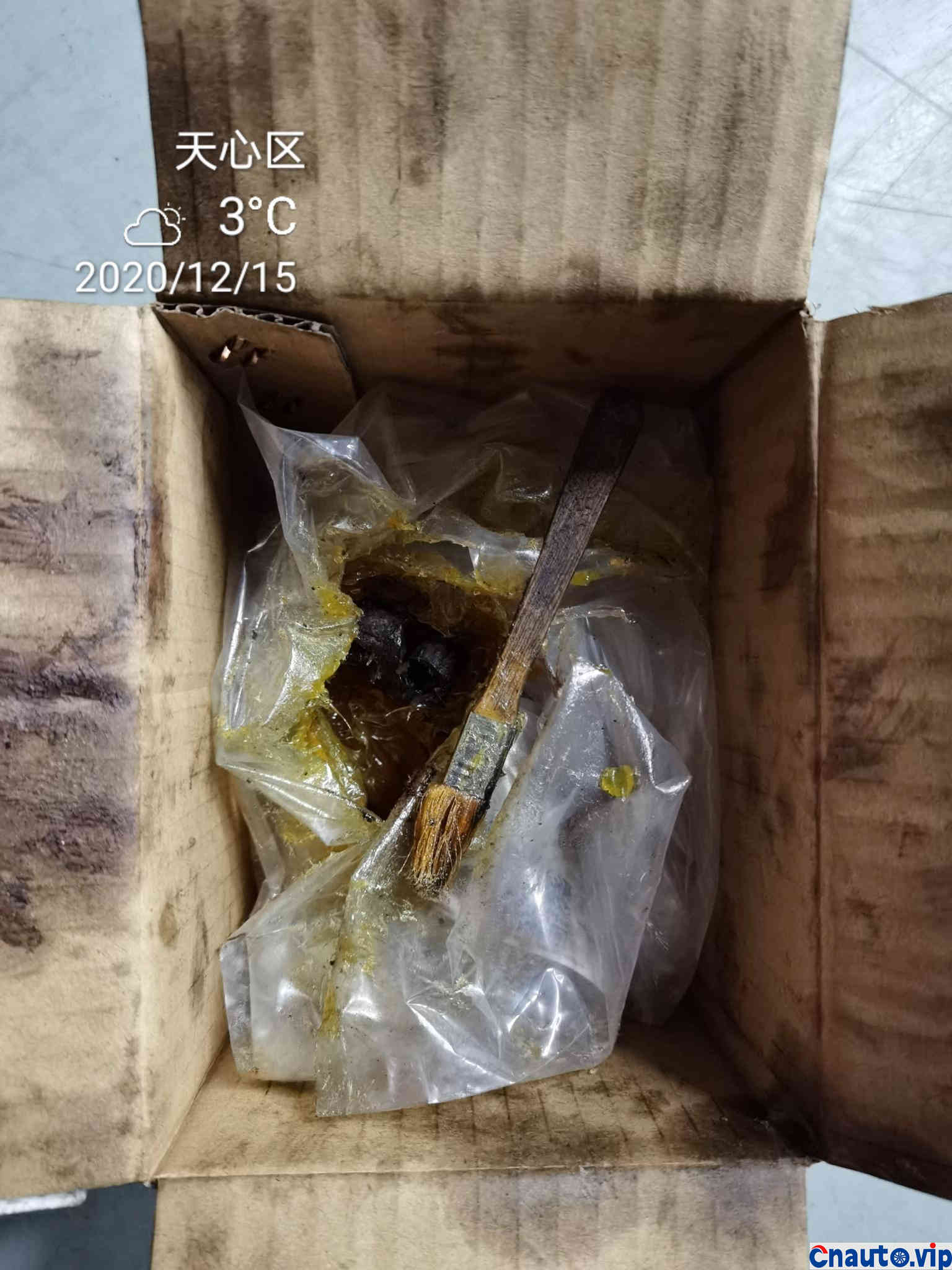

Spread butter.

Spread butter.

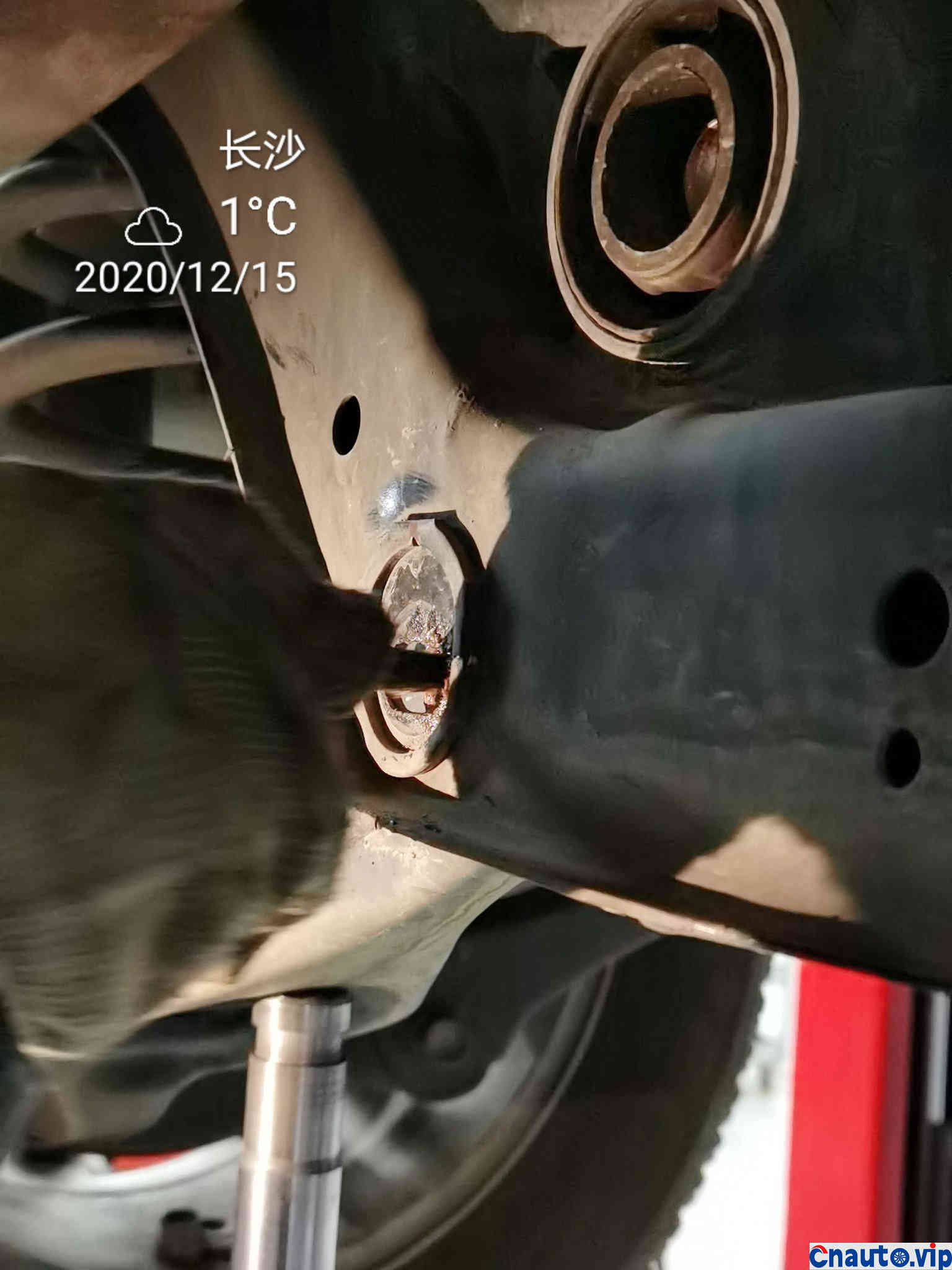

Remove the front locating bolt.

Butter.

The screw at the rear is not rusty yet.

Spread butter.

Hot Information

Tesla Autopilot and similar automated driving systems get ‘poor’ rating from prominent safety group

April 1, 2024

April 1, 2024 Localization of EV parts without production scalability may not help cut EV price, says President, Amara Raja

March 27, 2024

March 27, 2024

JCTSL may turn bus stands into charging points for e-buses

March 27, 2024

March 27, 2024 You May Like