Model: 2011 A4L chassis code B8

Cumulative mileage traveled: 127,000 kilometers

Fault symptom: When you step on the brake to stop, the suspension squeaks

Reason for failure: Cracks of upper swing arm rubber sleeve

Maintenance plan: Replace the upper swing arm rubber sleeve separately

When the car was about 70,000 kilometers away, the original factory upper swing arm rubber sleeve cracked, and the upper swing arm rubber sleeve was replaced separately. At that time, the rubber sleeve seller said that the warranty was 50,000 kilometers for two years. Now, it has been driving for three years and 57,000 kilometers. The merchant is still conscientious.

I will not choose the product from the last time for replacement this time. Based on the principle of saving money, I will find accessories again on Taobao.

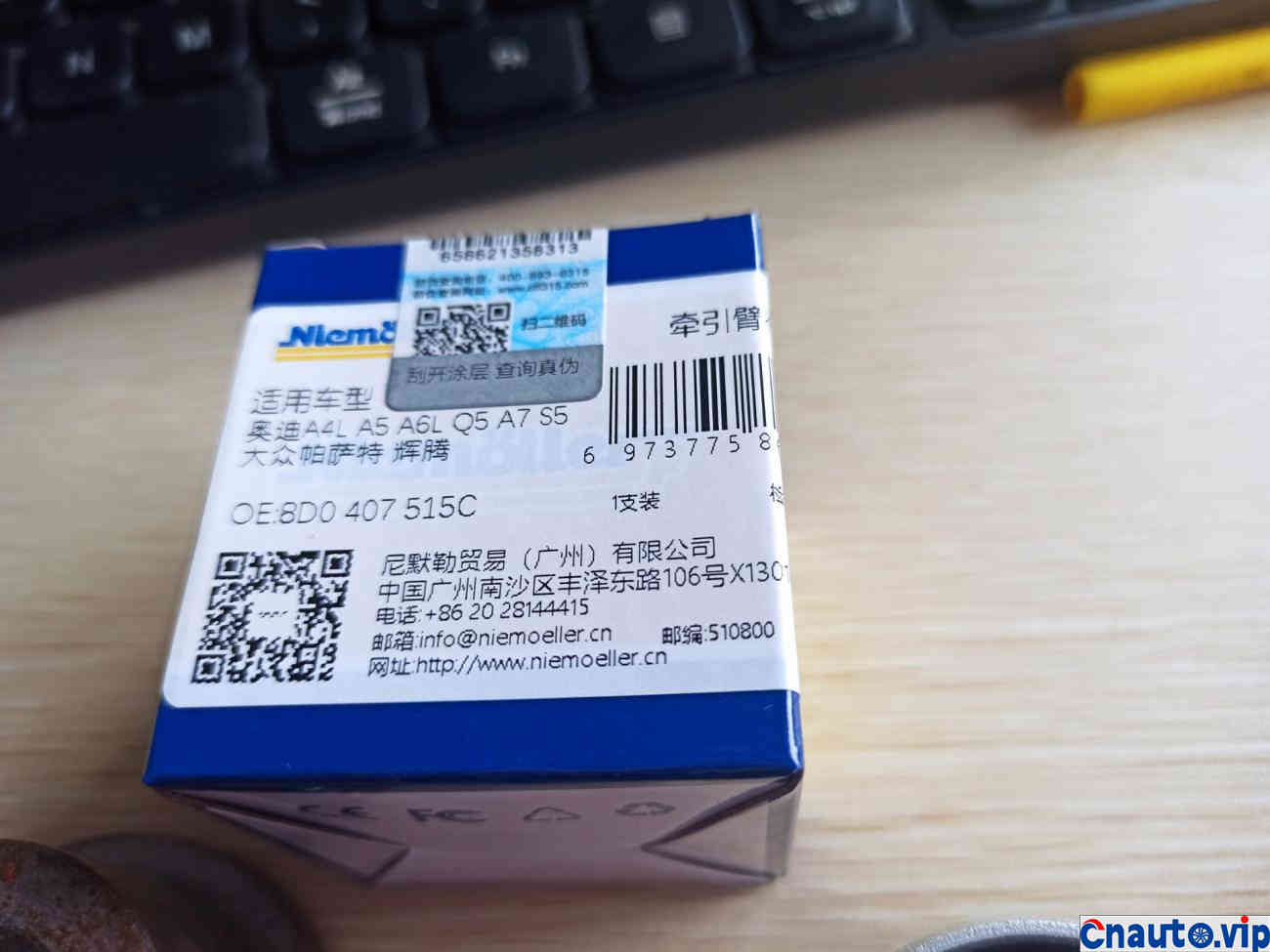

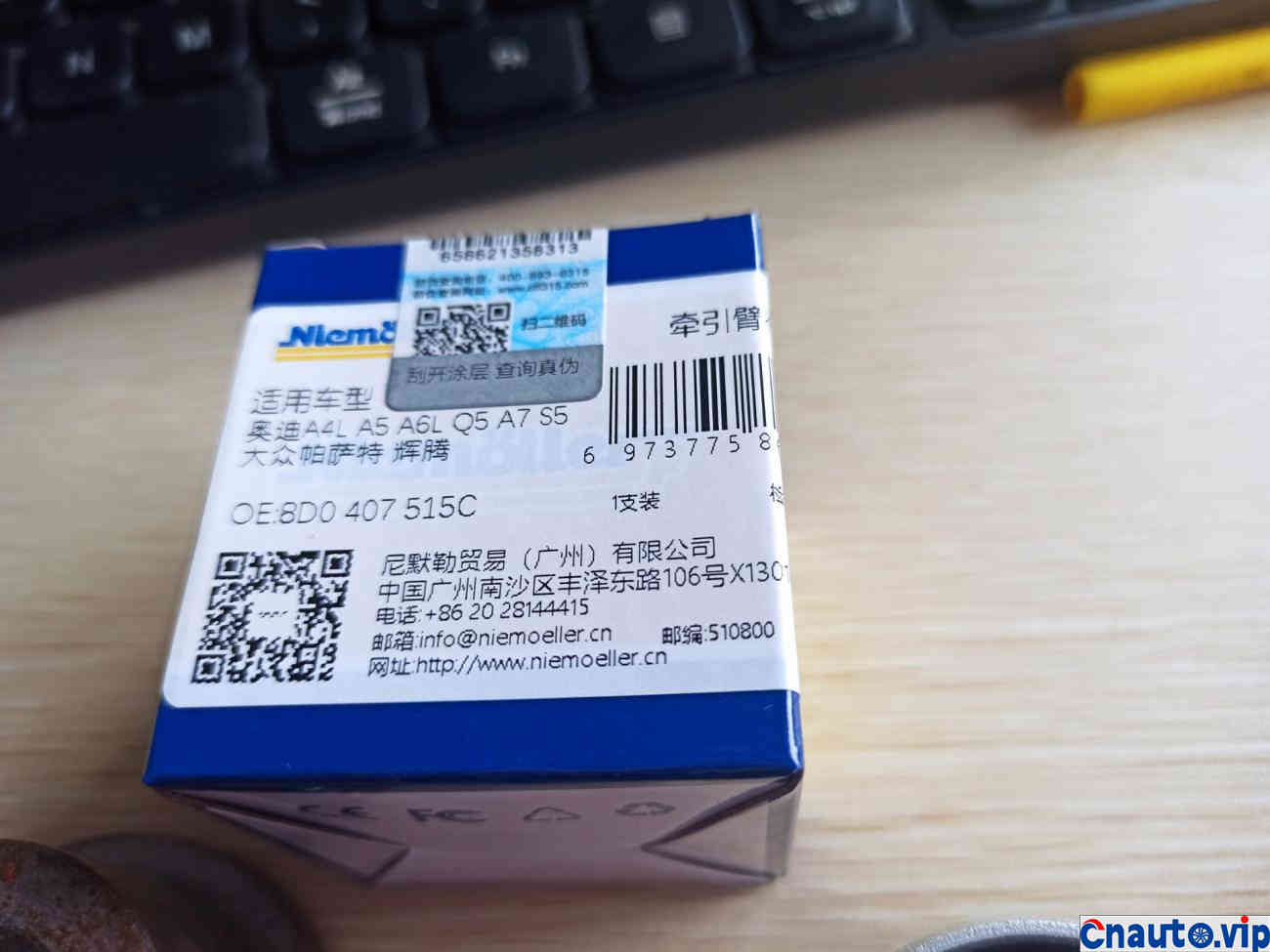

The brand is “NIEMOLER” and “Nimoller” in Chinese. I placed an order after reading the product introduction. The goods arrived today. Open the box and have a look.

Rubber sleeves are packaged separately

Product details and workmanship are okay, no extra rubber burrs The handwriting is also clear

Don’t worry about the accessory number. Just have the same size

There were 4 rubber sleeves in total. After rummaging through the cabinets and finding the rubber sleeve mold I made back then, it was a little rusty.

One end of a mold is pressed out and the other is pressed in. Photo of this mold. Several sellers on Taobao and Salted Fish have stolen my photo as a promotional photo on the front page. I despise it here For example, the seller in the picture below… At that time, I replaced the two molds made by the curved arm and the upper swing arm, posted a post, and the pictures were stolen like this.

Due to the small size and small gap at the extruded end of the rubber sleeve, it is easy to get stuck in the swing arm when pressed out. This time, 60 threads were lost on the lathe, which means 30 threads were fed in the tool.

The car is ready to go out for replacement after 60 wires are lost All I lack is a press

First measure the size from the shaft center to the leaf plate. After replacing the rubber sleeve, individually lift the brake disc assembly to this size and tighten the swing arm screws, so that the rubber sleeve is in a non-distorted position and the service life is prolonged.

Since the B8 suspension space is large and the top position is large, the swing arm can be removed without moving the shock absorber and removing the tire with a jack on the flat ground.

The upper swing arm is divided into an upper straight arm and an upper curved arm The upper curved arm is close to the instrument panel The upper straight arm is close to the front side

Loosen the screws on the horns and remove the fixing screws at the back

This is both taken down

Press out the old and put on the new

The new basics are in place, just fine tune the spacing

One has been pressed and ready to be loaded

One side is in place and assembled.

Check and tighten all screws on one side and replace the other side with the same method

No pictures will be posted on the other side. The replacement will be completed in an hour, and the two front wheels will be dynamically balanced.

Cost? This repair and replacement work cost 100 yuan, materials 55*4=220 yuan

As for how long this rubber sleeve will last, I look forward to the next 50,000 kilometers!

April 1, 2024

April 1, 2024  March 27, 2024

March 27, 2024

March 27, 2024

March 27, 2024