Chapter 3 of 3400 on Lao Eighth, installation of oil pump and oil pan in middle cylinder

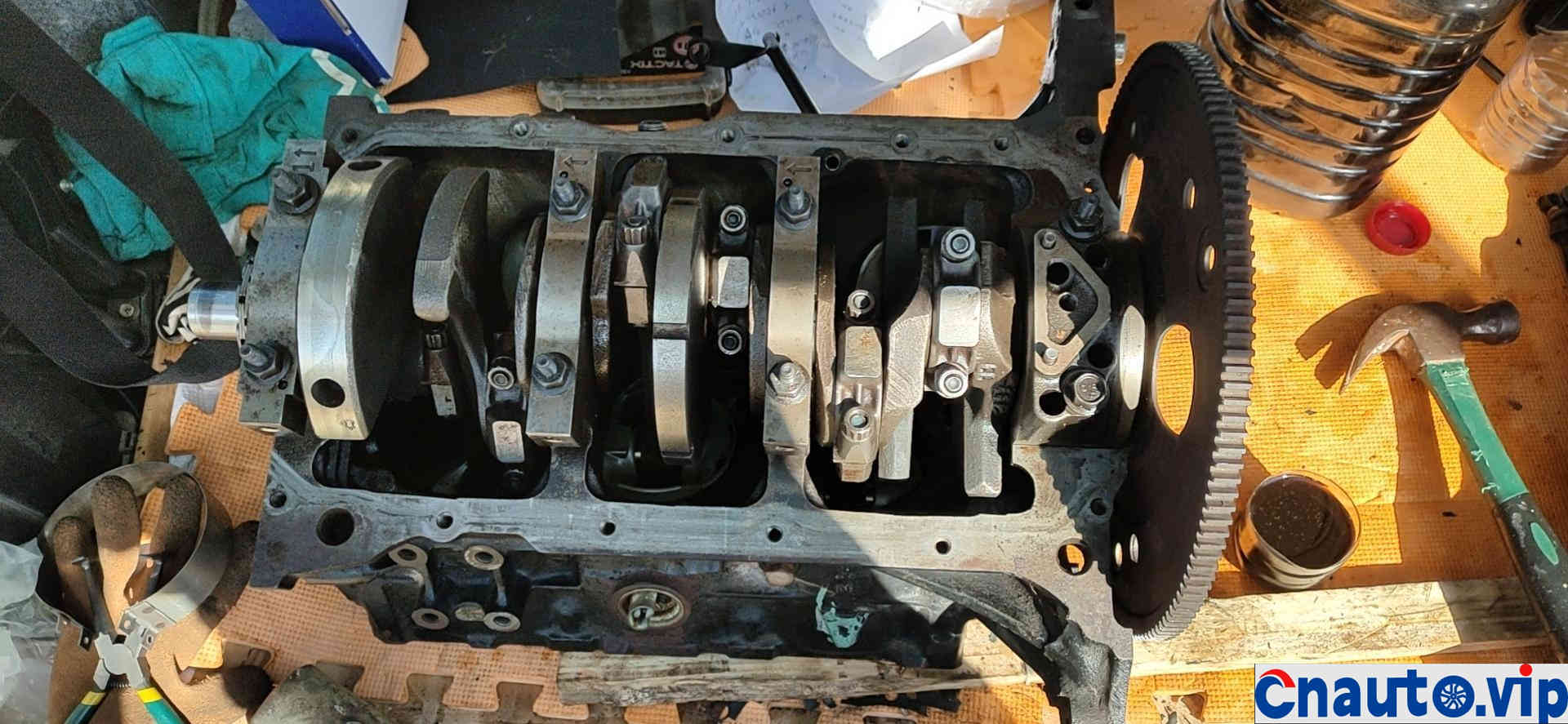

The matching of the connecting rod bearing cap, that is, the crankshaft with small bearings, has become the most troublesome issue. I studied it for a day last time. Today, I found that there was a problem with the installation steps, and I removed the timing and valve jack rods. After removing it, continue to work on the piston and connecting rod bearing caps

Look at the bumps facing the flywheel side, which is different from others

I originally wrote the number, but then I mixed it up again. It lasted for more than a day

Look at the photos taken while tearing them down over and over again

started

I found that the inclination of the bearing cover was different, and I asked the mechanic and said I didn’t pay attention to it.

Later, I studied the pictures and found that the slope from the song to the end of the song was getting smaller and smaller

Later, I studied the pictures and found that the slope from the song to the end of the song was getting smaller and smaller

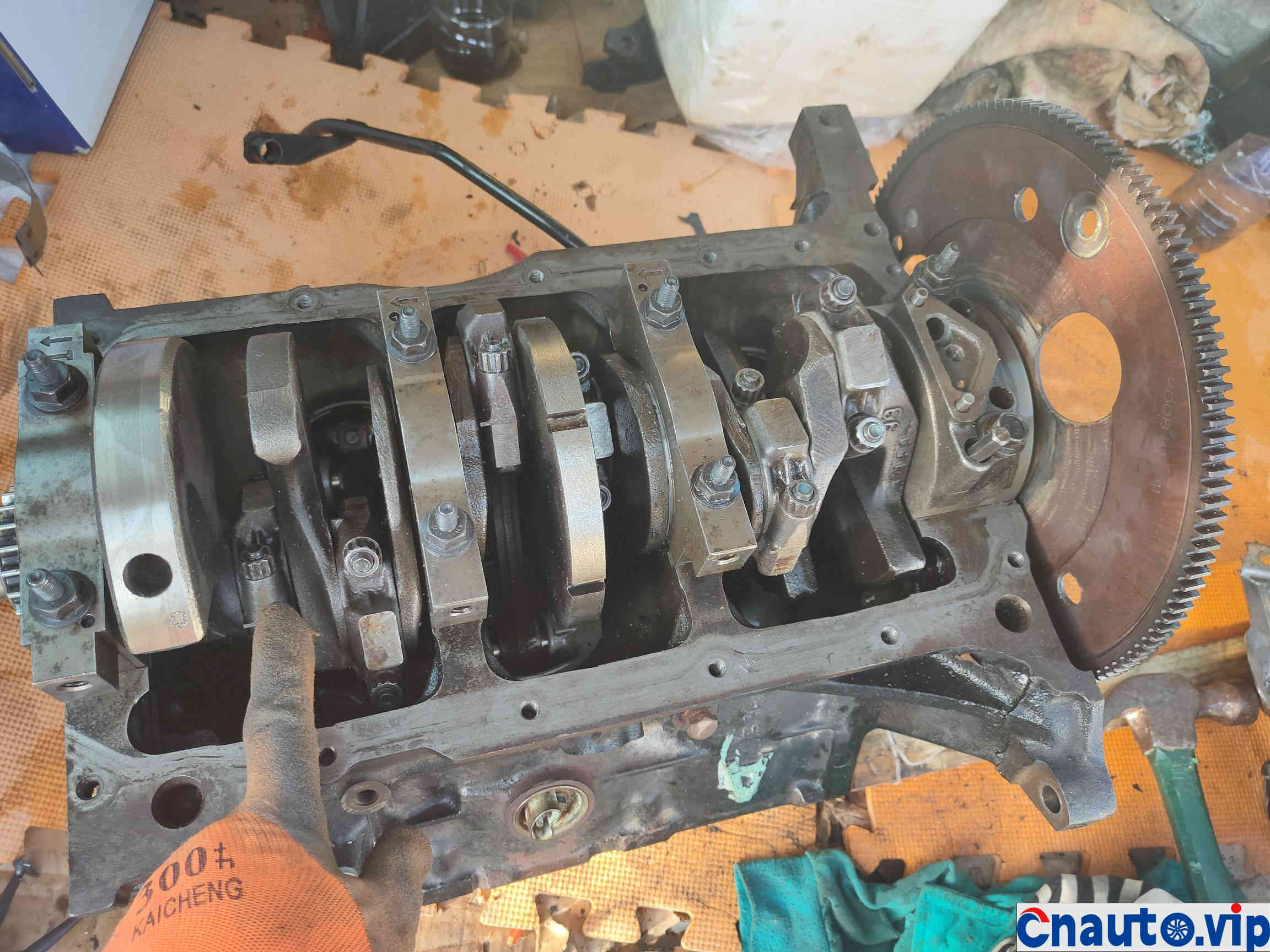

The piston was disassembled and disassembled several times over and over, and it collapsed

It was installed this way, and the piston had no direction markings.

Lock the bearing cap, but the flywheel still won’t turn

After the piston ring was replaced, the resistance in the cylinder tube was significantly greater than before, so we had to continue to install it down.

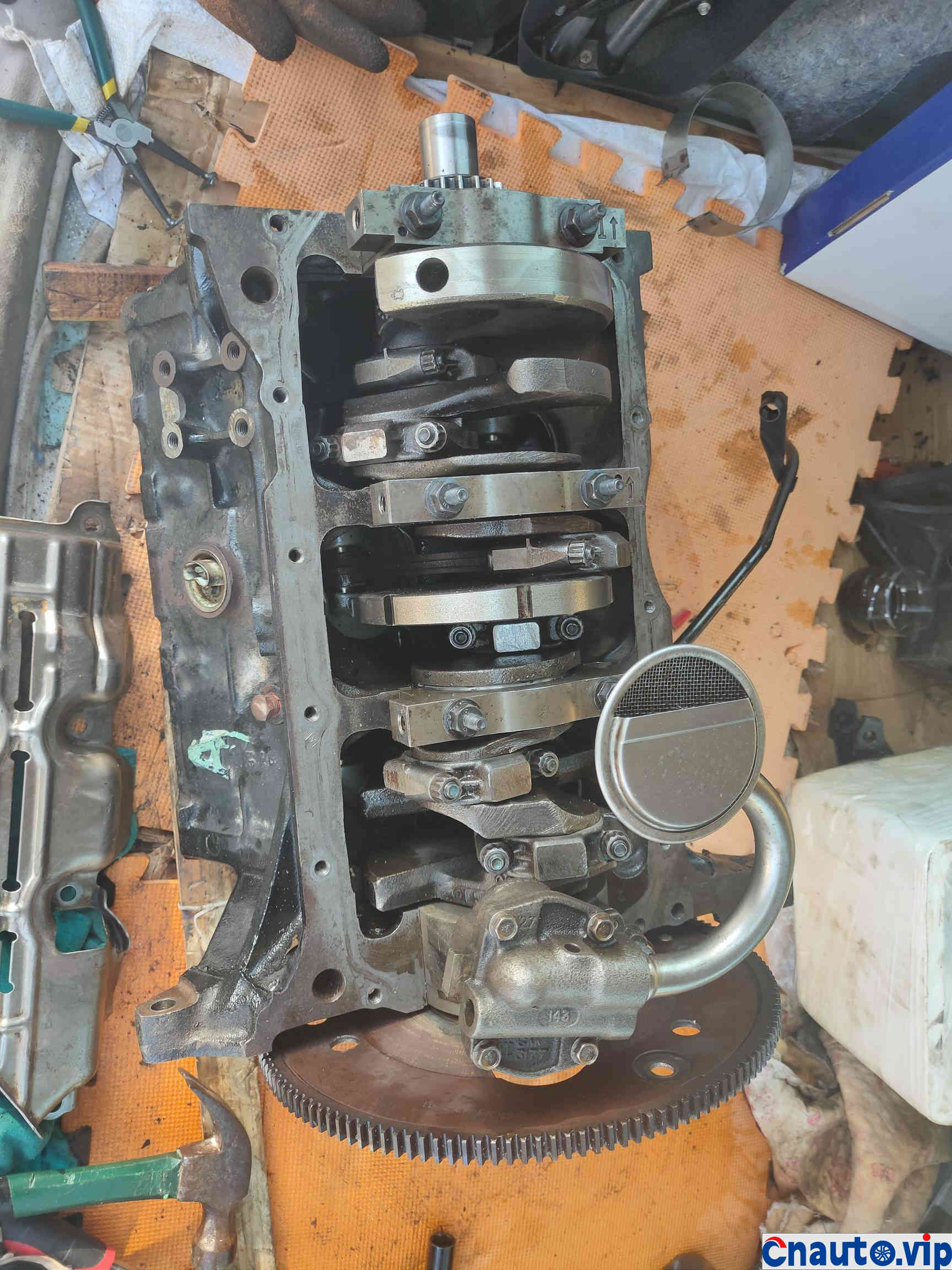

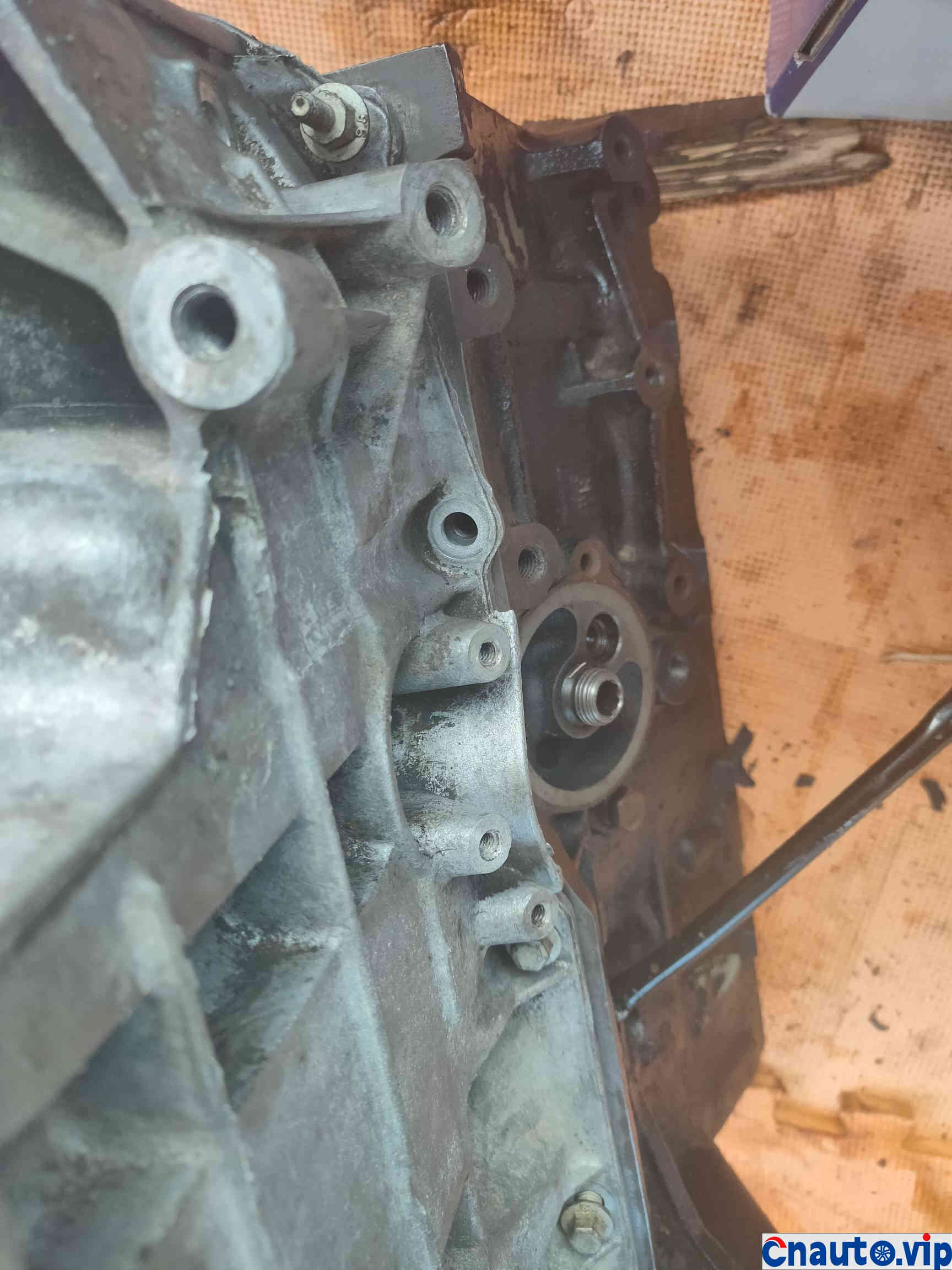

Remember to install the oil pump shaft and install the oil pump

Lock oil guide

Oil pan gasket, riders say it will easily leak without glue. It is estimated that we will need to rework, but we should not apply glue first, and the original factory did not apply glue either. There is no one that Lao Eight does not miss, it is too difficult

One oil pan screw is missing, so I have to go home and look for it

Oil pan side screws, 3400 has rubber gaskets, 2500 has no more

The 2500 foot glue fixing frame was used, and the new foot was used. I didn’t take the fixing screw, so I’ll lock it another day

Try the 2500 starter and there seems to be no problem. I am going to make a tool to turn the flywheel. If I turn it directly by hand, I will definitely not be able to turn it.

Generator-transformer connection frame

Lock the three screws, install the 7x crankshaft sensor in addition, and re-wrap the sleeve when the wiring harness is aging

Winter is entering, and it gets dark early. call it a day

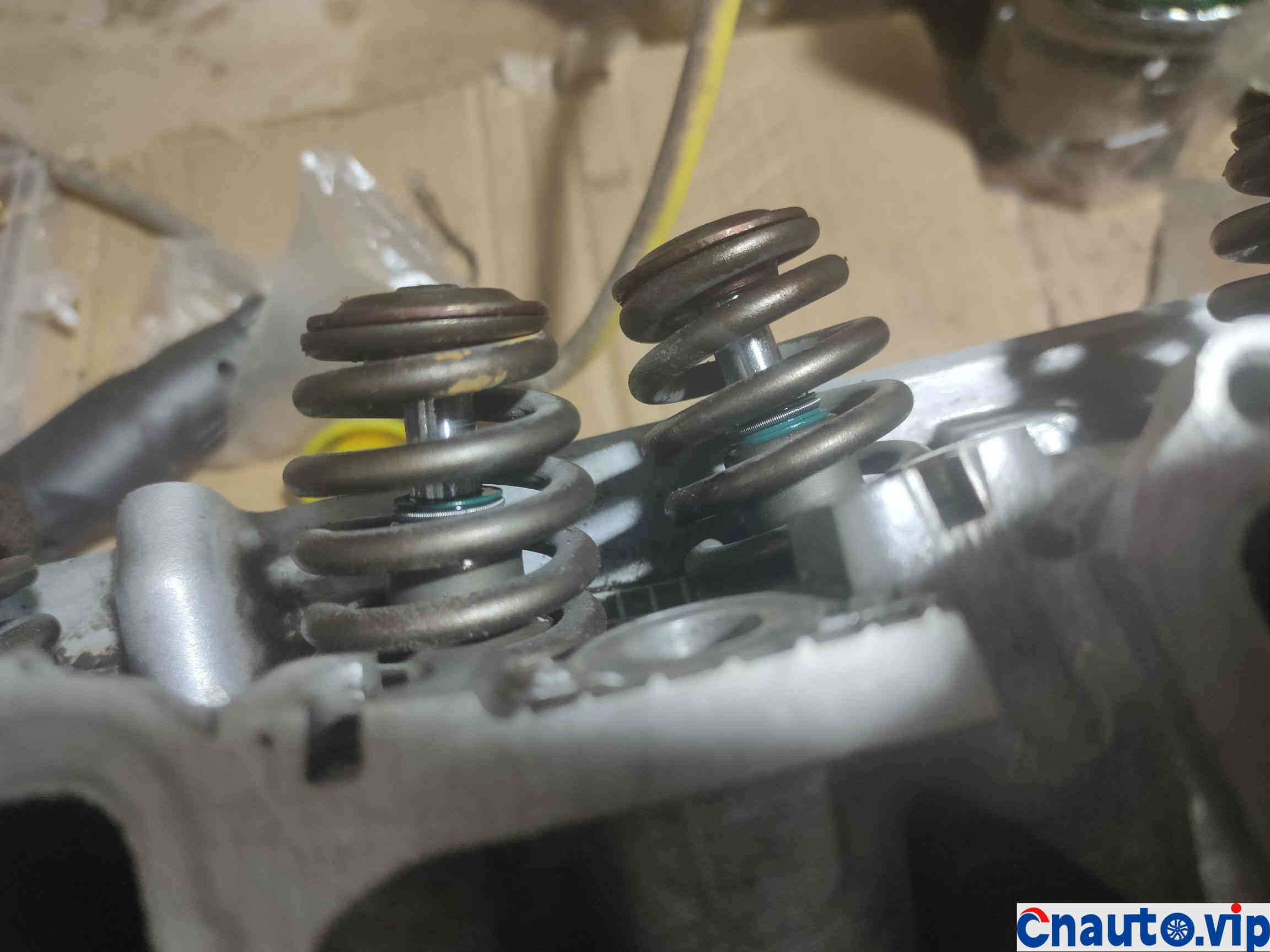

valve key

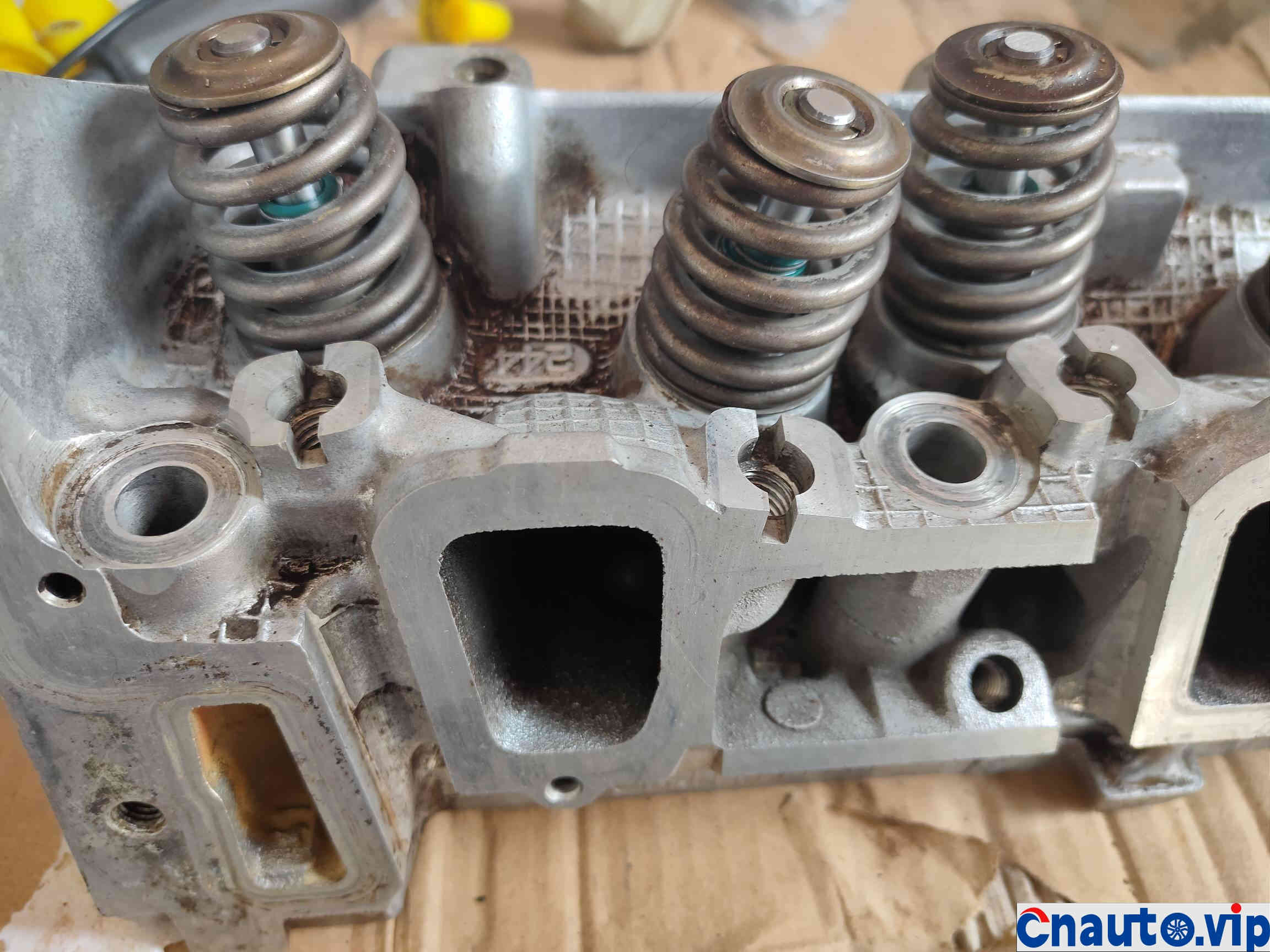

Install the cylinder head with a new valve seal

The spark plugs on the two nose heads, 3400 on the right, have been replaced with gas. I wonder what model of the original spark plugs are.

Rear cylinder head assembly

valve installation

The valve oil seal is too tight to install

New equipment, originally required to ventilate the door catheter, but was not replaced later. It’s not hydraulic. It can’t be done.

A 13-piece extension wrench is necessary for locking small tiles

abrasive valve

difficult conditions

new tools

Because it is difficult to get up early in the morning in winter, I work all day and have little time. The road is long and long, and I will search for it from top to bottom![]()

Hot Information

Tesla Autopilot and similar automated driving systems get ‘poor’ rating from prominent safety group

April 1, 2024

April 1, 2024 Localization of EV parts without production scalability may not help cut EV price, says President, Amara Raja

March 27, 2024

March 27, 2024

JCTSL may turn bus stands into charging points for e-buses

March 27, 2024

March 27, 2024 You May Like