[Daily car maintenance] 4S stores rarely have equipment. Have you heard of dry ice blasting to remove carbon?

Hello everyone, this is a column focusing on car repair and maintenance. There are car mysteries you don’t know, and it will teach you how to avoid the big pits on the road of car ownership. I believe that not only you but also many people have a certain sense of obscurity about the car aftermarket, which will help you uncover the unknown stories of car repair and maintenance.

Carbon accumulation is an unavoidable problem for almost every car, whether Japanese, American, European, high-end or low-end brands can not escape the clutches of carbon accumulation. As soon as more carbon accumulates, engine failures follow, and jitter, increased fuel consumption and power decline are all on its menu.

The same is true of the engine in front of us. after stepping into 100,000 kilometers, the above symptoms began to come true step by step.

The same is true of the engine in front of us. after stepping into 100,000 kilometers, the above symptoms began to come true step by step.

After removing the spark plug, check the carbon deposition in the cylinder with an endoscope. The top of the piston gathered a large amount of carbon, a thick layer, completely can not see the bright white of the previous aluminum alloy.

So much carbon deposition will have a huge impact on the engine and must be removed.

So much carbon deposition will have a huge impact on the engine and must be removed.

It is difficult to remove carbon from the piston top because the piston is on the innermost part of the engine. Although the use of foam cleaning can remove some of the carbon deposits, but in order to remove thoroughly, you need to add foam several times, both the time cost and labor cost are very high.

But the car in front of me uses a new way to remove carbon dioxide from dry ice, which is what we often call solid carbon dioxide.

But the car in front of me uses a new way to remove carbon dioxide from dry ice, which is what we often call solid carbon dioxide.

These white strips are dry ice, which looks very similar to the state of the ice, and they will come in handy in a moment.

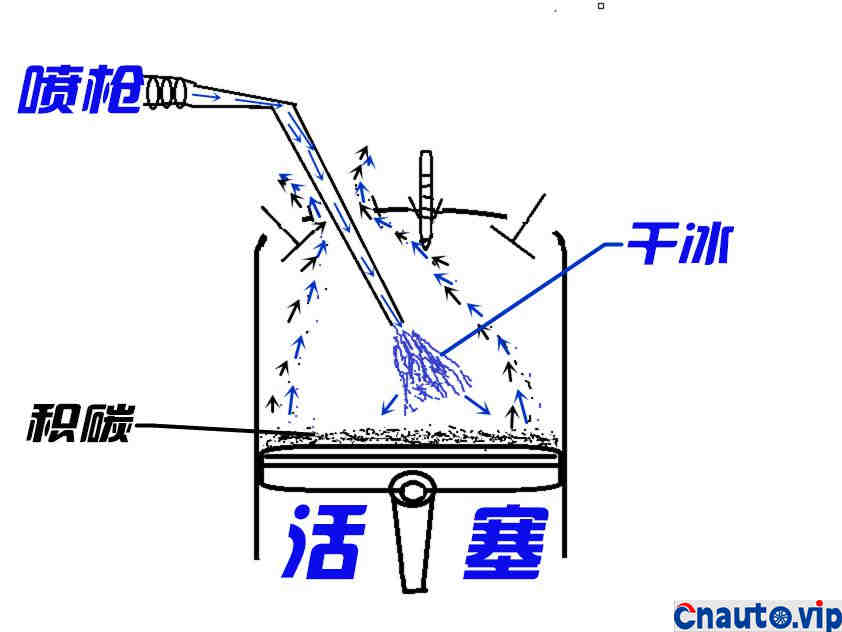

There are two main principles of carbon removal from dry ice.

A high speed impact force

Using high-pressure air to give dry ice a certain acceleration, the impact of dry ice can wash down the deposited carbon, which is very similar to the method of sand blasting and carbon removal of walnut sand in this respect.

A high speed impact force

Using high-pressure air to give dry ice a certain acceleration, the impact of dry ice can wash down the deposited carbon, which is very similar to the method of sand blasting and carbon removal of walnut sand in this respect.

Second thermal shock effect

When dry ice comes into contact with carbon deposits, it will sublimate instantly and absorb a lot of heat. Carbon deposition will also cause cracks between the rapid cooling and the piston surface, which are more likely to lead to carbon deposition and peeling off between the cylinder block.

When dry ice comes into contact with carbon deposits, it will sublimate instantly and absorb a lot of heat. Carbon deposition will also cause cracks between the rapid cooling and the piston surface, which are more likely to lead to carbon deposition and peeling off between the cylinder block.

Remove the spark plug and insert the nozzle of the decarbonizer directly into the cylinder to remove carbon.

Inside the cylinder, dry ice constantly hits and accumulates carbon, and the residue of carbon deposition will gush out of the cylinder body with the recoil of high-pressure air.

In order to cope with different engine designs, there are also a variety of nozzles to choose from. The spark plug positions of some American models and V-engines are so unique that it is difficult to see, so you need some pipes that can be bent at this time.

It can be seen on the spray gun that the carbon deposit has been beaten into powder, and the carbon deposition has been nearly completely extinguished under the pressure of more than ten BAR.

After removing the carbon deposit on the piston top, the original bright metal color can be seen again.

The method of removing carbon from dry ice takes almost the same time as that of walnut sand, each cylinder takes about ten minutes, and it takes more than an hour for a four-cylinder engine to operate.

In the past, you may never think that dry ice can also be used to repair cars. But it happened right in front of your eyes, and the effect was amazing. Technology is the primary productive force, this sentence is really more and more empathy, as a practitioner in the automotive aftermarket, deeply shocked by the power of science and technology. Perhaps in the future, with the emergence of more and smarter products, the automotive aftermarket can boast a bigger step forward.

Hot Information

Tesla Autopilot and similar automated driving systems get ‘poor’ rating from prominent safety group

April 1, 2024

April 1, 2024 Localization of EV parts without production scalability may not help cut EV price, says President, Amara Raja

March 27, 2024

March 27, 2024

JCTSL may turn bus stands into charging points for e-buses

March 27, 2024

March 27, 2024 You May Like