[Maintenance of a car every day] Eight years of MINI chassis sound, pulling out radish and bringing out mud

Common sense of car maintenance and repair, and the reasons for car failure can be found here. If you want to truly understand your car, this is a good way to add your car knowledge. It is an opportunity for you and me to get to know each other and a beginning to make new friends. No reprint without permission of the original work

A driver’s R57 convertible mini driving makes it very uncomfortable to hear the abnormal sound of the chassis. When the vehicle arrived at the store for inspection, there were really many problems. The chassis rubber sleeve was loose, the engine leaked oil, and the exhaust heat insulation panel was ruptured, causing resonance. We have replaced the lower arm rubber sleeve, balance bar rubber sleeve, turbine oil pipe, gasket, etc. This place is particularly grateful to our motorists for their trust and support. We have always insisted on using authentic parts to ensure that every vehicle after maintenance can drive safely on the road.![]()

A driver’s R57 convertible mini driving makes it very uncomfortable to hear the abnormal sound of the chassis. When the vehicle arrived at the store for inspection, there were really many problems. The chassis rubber sleeve was loose, the engine leaked oil, and the exhaust heat insulation panel was ruptured, causing resonance. We have replaced the lower arm rubber sleeve, balance bar rubber sleeve, turbine oil pipe, gasket, etc. This place is particularly grateful to our motorists for their trust and support. We have always insisted on using authentic parts to ensure that every vehicle after maintenance can drive safely on the road.

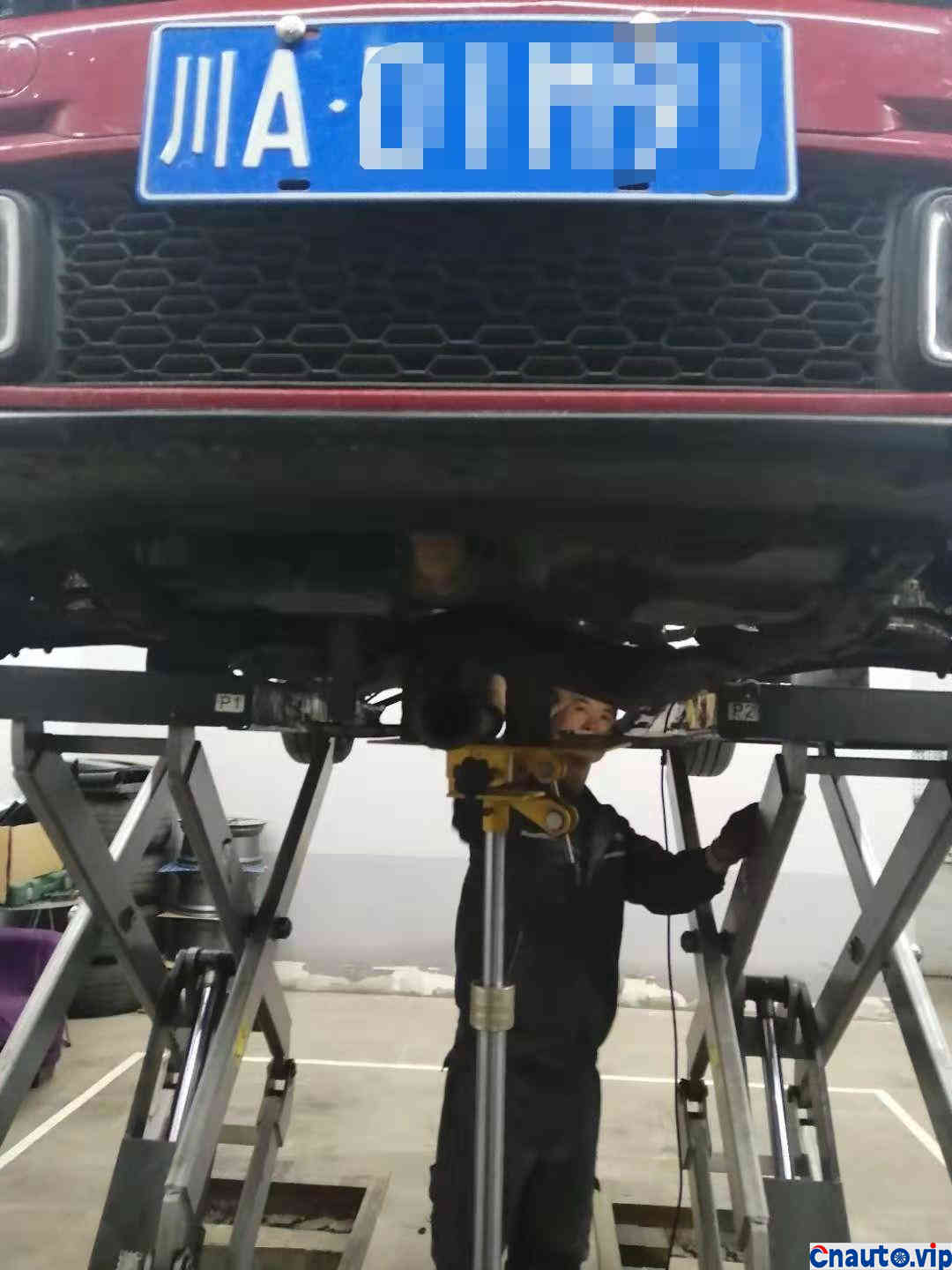

That’s right, it’s this rare R57. It took a while for the vehicle to be recovered. It took some time to repair the abnormal sound of the chassis.

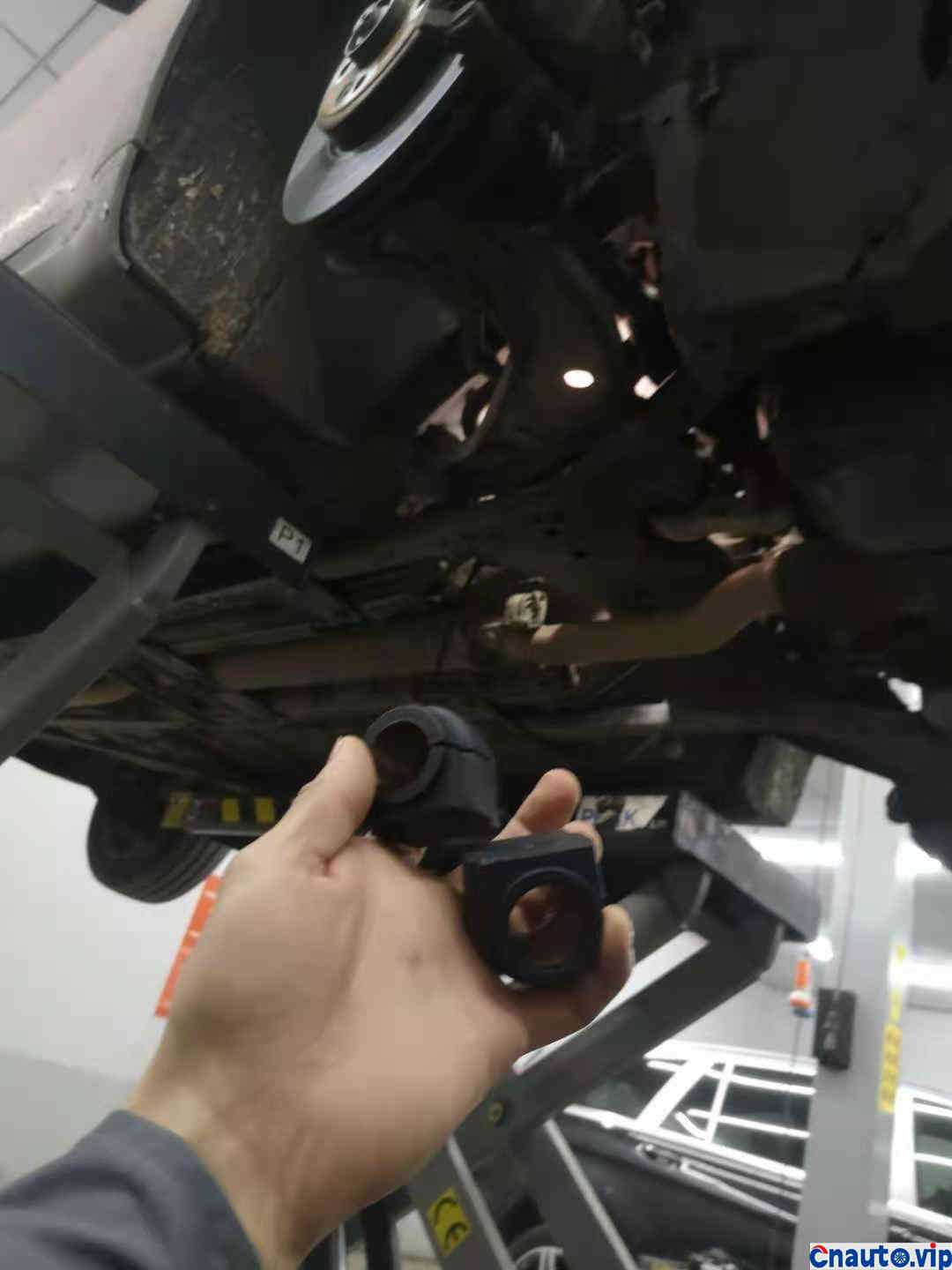

During inspection, we found that there was a large crack in the front curved arm rubber sleeve. After all, it had been used for so many years.

The front torsion bar rubber sleeve was also replaced together due to long-term use.

Changing these two rubber sleeves requires removing the front Yuanbao beam, which takes a long time.

The young man in the store was confused when he changed these two small parts. He was probably thinking about how they were designed…

Two separate rubber sleeves with spare parts.

Rubber sleeve replacement operation

The rubber sleeves of the two arms have been replaced

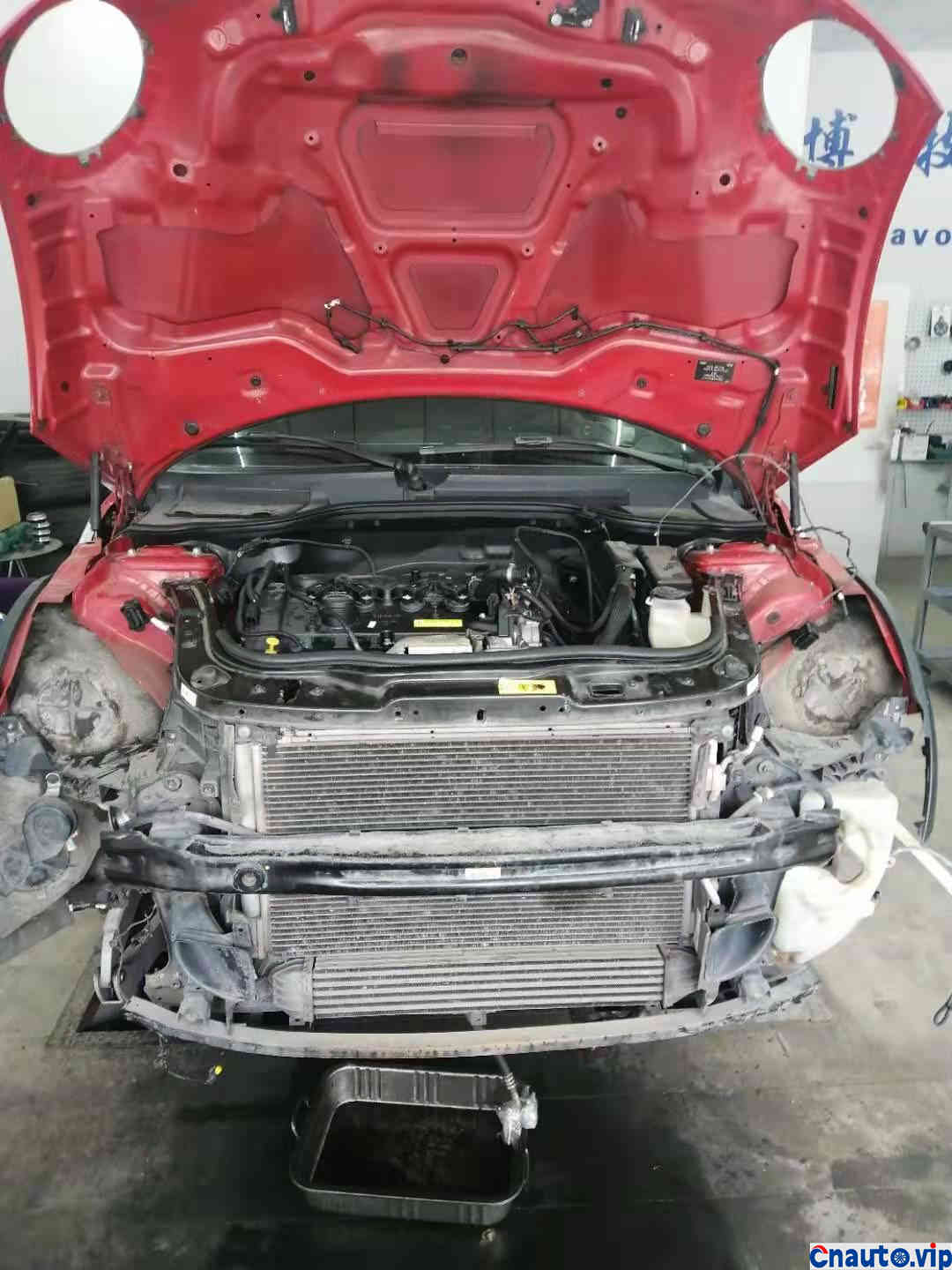

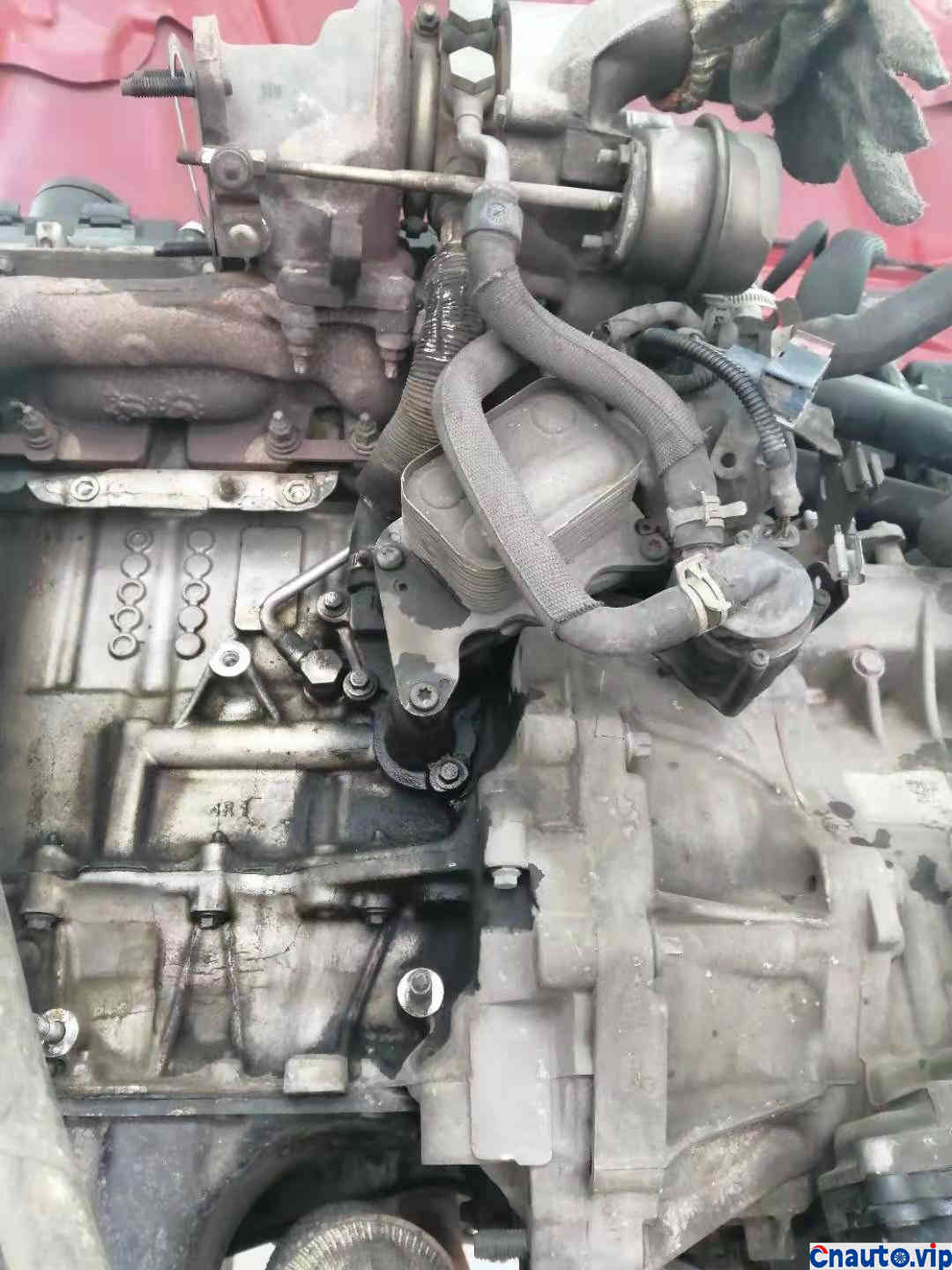

After repairing the chassis, the problem of engine oil leakage is then dealt with, which is also a common problem in the R series MINI.

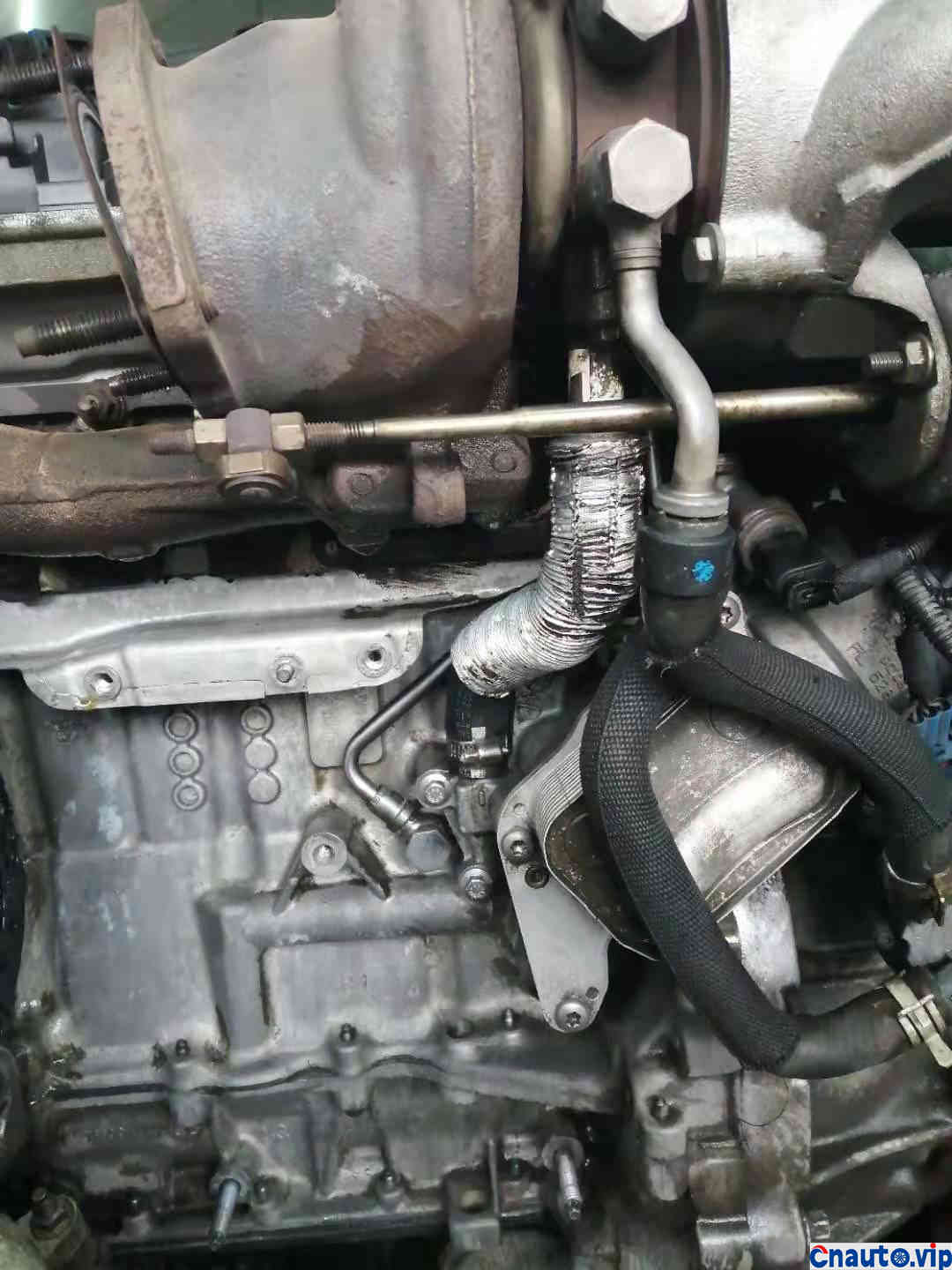

To deal with oil leaks, it is necessary to remove the Sanyuan. It is not convenient to maintain without removing the front nozzle, and it is easy to dispose of it cleanly.

Remove the three-dimensional heat insulation plate and clearly see the oil leakage point.

It can be seen that the oil has been leaking for some time.

Clean oil leaks to avoid dirt falling in when replacing sealing rings and oil pipes.

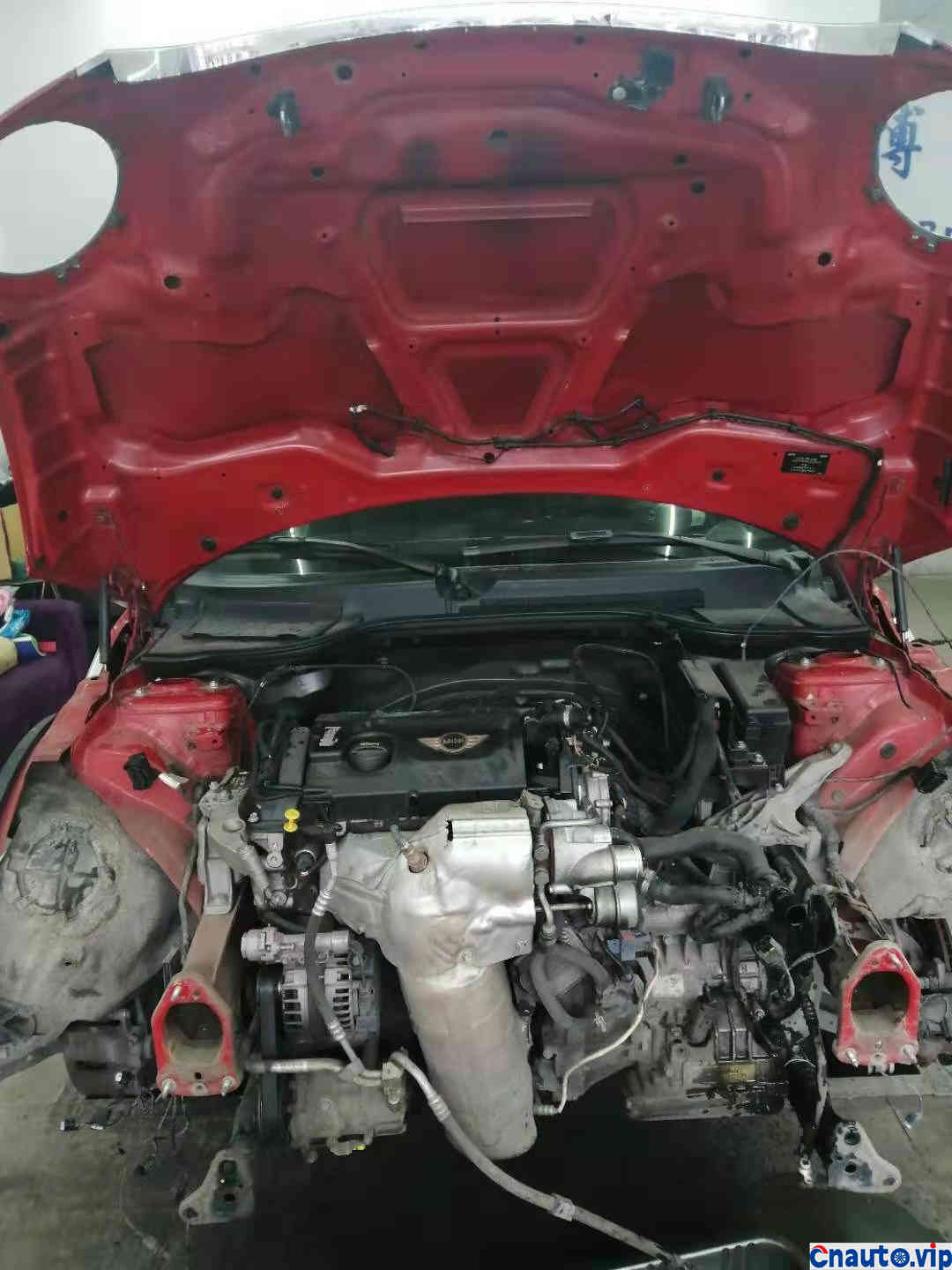

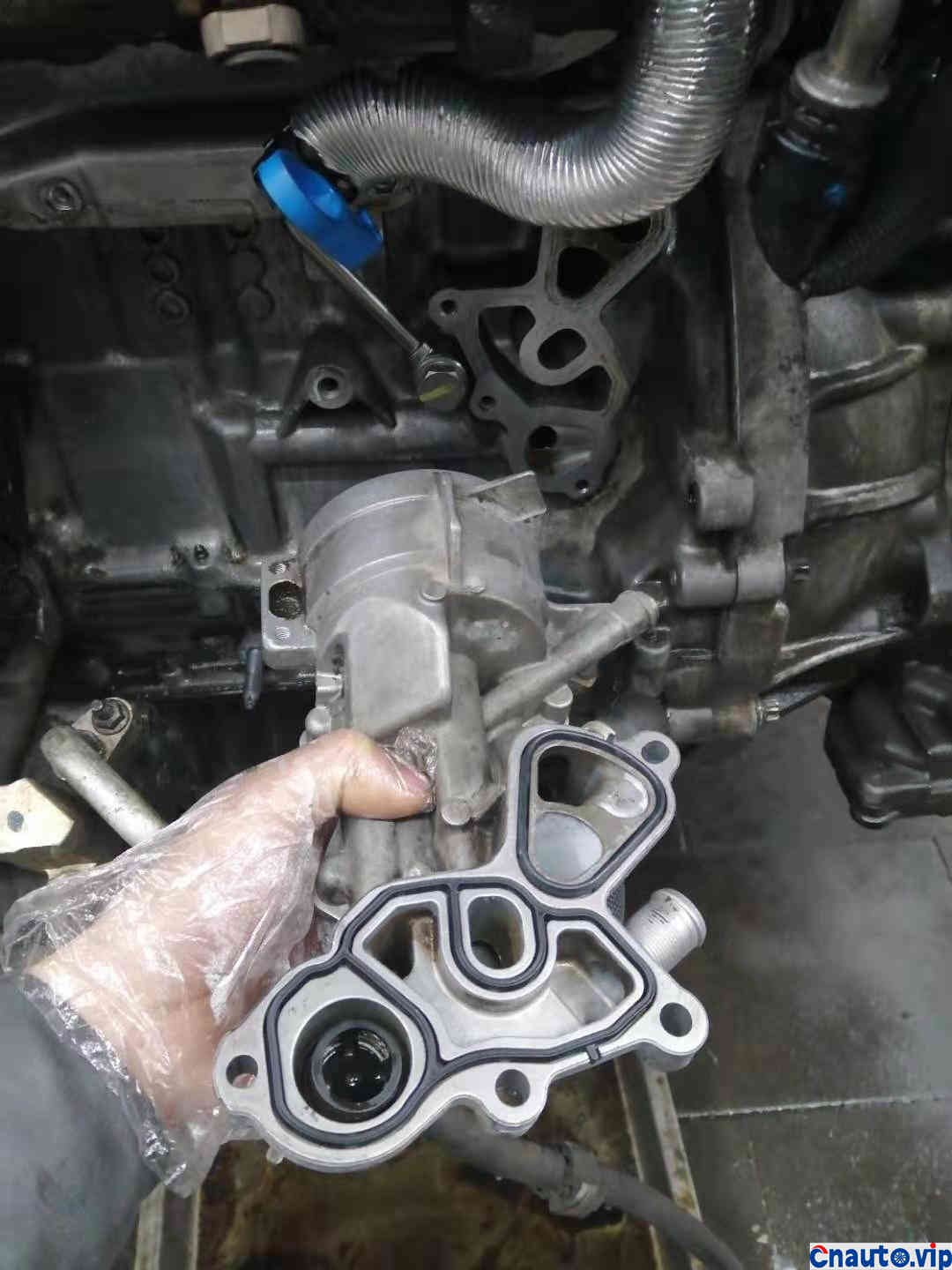

The oil pipes and sealing rings we prepared.

Replace the oil inlet pipe of the turbine, and hold the oil return pipe in your hand.

Make sure the sealing ring is used well, otherwise you will regret it

When replacing it, you need to check whether there is any problem with the check valve of the oil.

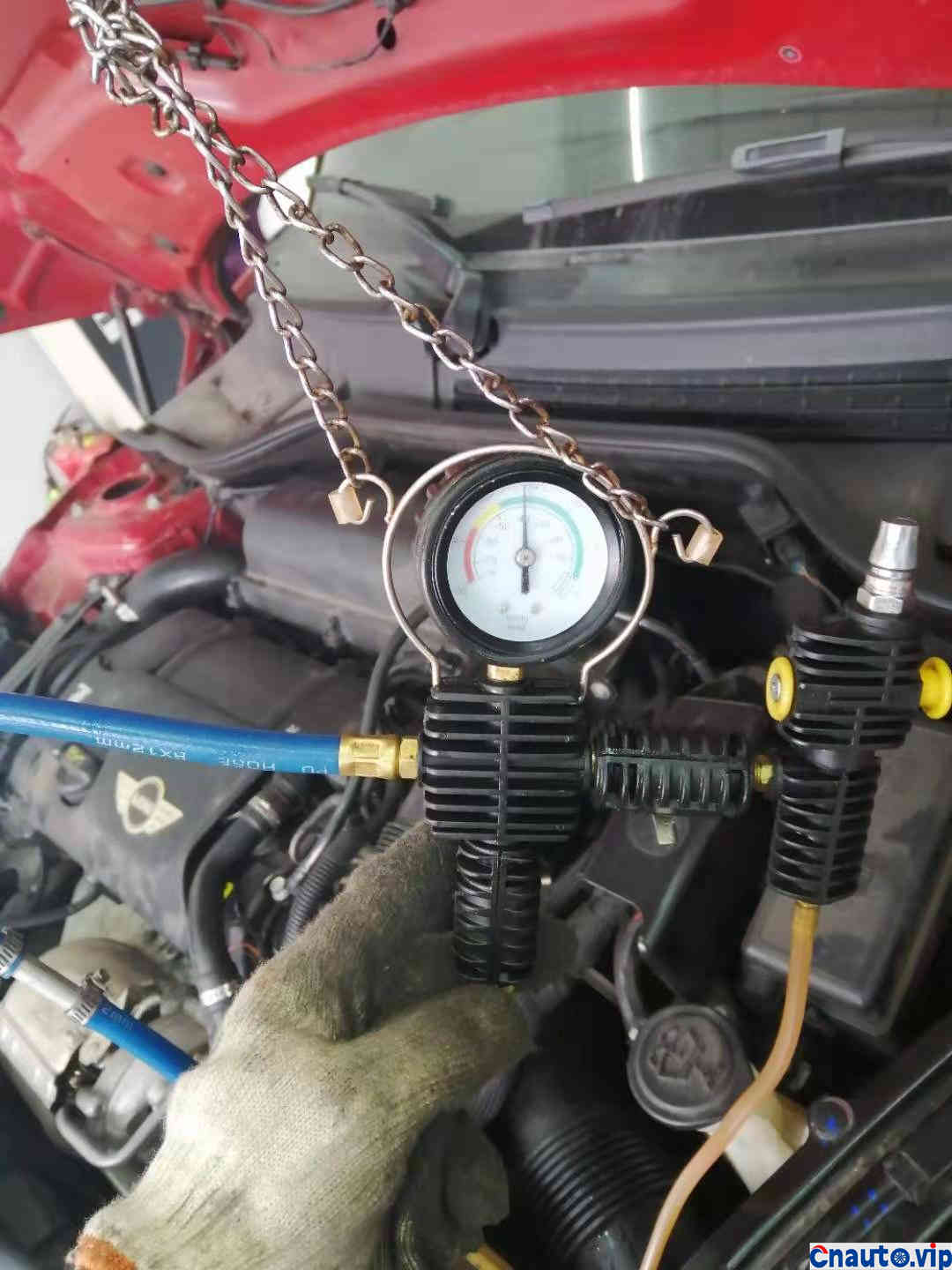

When adding coolant, you need to check the coolant system for leaks.

I found a problem with the balance bar boom while maintaining the suspension, and I was waiting for the spare parts to repair the oil leakage.

The vehicle has been inspected and tested without any abnormalities, and the engine cabin can be delivered after cleaning.

Hot Information

Tesla Autopilot and similar automated driving systems get ‘poor’ rating from prominent safety group

April 1, 2024

April 1, 2024 Localization of EV parts without production scalability may not help cut EV price, says President, Amara Raja

March 27, 2024

March 27, 2024

JCTSL may turn bus stands into charging points for e-buses

March 27, 2024

March 27, 2024 You May Like