Hard knowledge! What does the EA888 rely on to save fuel?

Https://www.xcar.com.cn/bbs/viewthread.php?tid=91233924

In fact, as an automobile major, I will give you some technical hard knowledge about why Tanyue is so fuel-efficient. Talk about EA888.

This is a long-term dominant engine, EA888. I have always had a question: why is it called EA888 directly after EA113? If you know something, you can reply below, anyway, the result is: it is a household name!

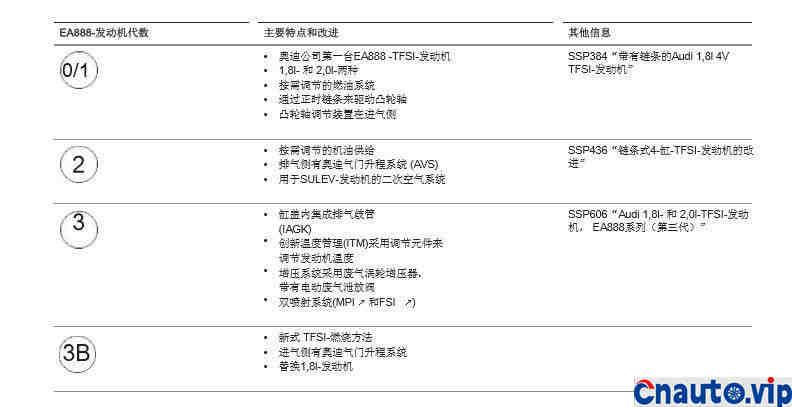

The improvements for each generation are as follows!

This is probably the engine that the Chinese know best. He let Qiu Ying hate the United States of my father, firmly implement the chairman’s idea of strict governance of the company’s my boss. And I was forced to learn English when I was a child. I know several English words at the same time. MPI,FSI,TFSI,AVS, wait. These are the names you’ve heard. I’ll tell you some stories about the latest EA888 that you may not have heard of.

You don’t know, AVS!

If it is translated into Chinese: variable valve lift system, it is estimated that 1/10 of people will already understand it.

He and Honda’s VTEC actually have the same meaning in Chinese. It also includes Valvetronic.

To put it simply, if you want to stir-fry a good meal, you must put reasonable salt. More salt is salty, but less salt has no taste.

If you want to have a good engine, the first step to master is air and oil. When and how much air is put in. The time it takes to put in the air. Is controlled by the valve. The valve is divided into intake valve and exhaust valve.

How does the engine control the intake and exhaust valves?

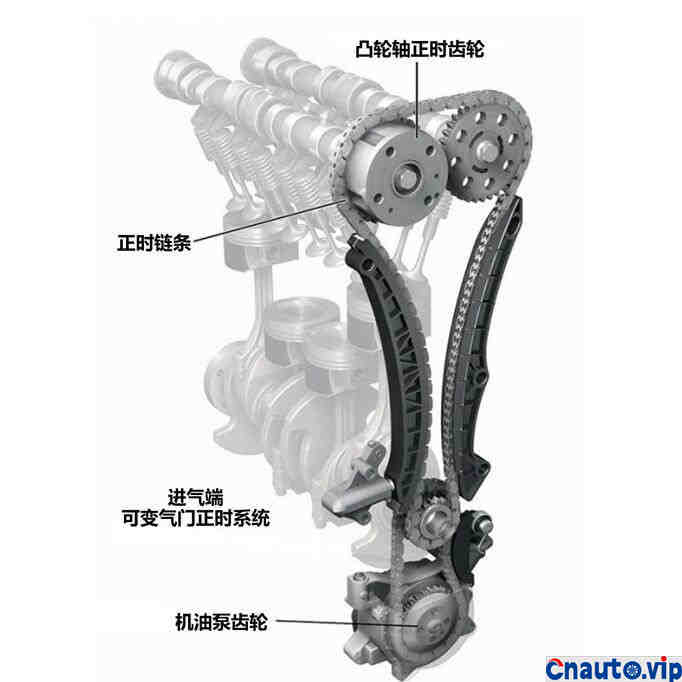

The first stage: timing chain: evolution words single overhead camshaft (SOHC), double overhead camshaft (DOHC)

The engine drives the crankshaft by the reciprocating motion of the piston. Transmit power. But at the same time, how does the engine coordinate the piston with the intake and exhaust? When the piston is discarded at the top of the motion stroke, the exhaust valve closes and the intake valve opens automatically. Before the ignition, the valves and exhaust valves are closed to ignite the gasoline. Before the gasoline pushes the piston to move to the top and the exhaust valve opens again?

It is a timing chain, which links the crankshaft to the camshaft and controls different speed ratios through the chain to coordinate the relationship between the piston and the opening and closing of the intake and exhaust valve. The opening and closing of the valve is controlled by the camshaft. Later, it was further developed from single overhead camshaft to double overhead camshaft to control intake and exhaust respectively.

The second stage: variable valve timing system

This is the same reason as you breathe. When you sit, you can breathe evenly. But if you are nervous, take a deep breath, increase the time you open your mouth, and step back when you shut up.

If there is only a timing system, it will solve the basic problem of intake and exhaust. It is no problem for this engine to run at a certain speed and torque all the time. Imagine a water wheel moving at a single speed. It’s basically at that level. But you blow the throttle so that the car has a reasonable ratio of gasoline to air at all revolutions. You can’t do it. This requires a variable valve timing system. To close the intake and exhaust valves ahead of time or later. To more precisely control the amount of air entering. So various companies have developed variable valve systems with different names.

The focus is on the outside controller. If you take apart the engine of the engine, the two discs driven by the timing chain are his control system.

Phase III: variable Valve lift system (AVS)

If you take breathing as an analogy, this means that you should not only control the time when you open your mouth and shut your mouth, but also control the size of your mouth and the depth of your breath.

That is to say, the common VVT variable valve timing system can only adjust the opening time of the intake valve or intake and exhaust valve, while the Volkswagen AVS system can further control the opening lift of the intake valve. Mechanical structure of the Volkswagen AVS variable valve lift system: there are two sets of cams with different angles on the camshaft responsible for controlling the intake valve and a spirally grooved sleeve responsible for changing the lift. The spirally grooved sleeve is controlled by an electromagnetic drive to switch between two different sets of cams and change the opening lift of the intake valve.

As shown in the picture

The method of direct control with multiple solenoid valves is shown in the figure.

If you understand, you will fully understand the technical principles of all the following companies (the means of implementation are not the same).

VTEC, i-VTEC, VTEC-E-the name of Honda Technology Research Industry.

General name of MIVEC- Mitsubishi Motors.

The name of AVCS- Fuji heavy Industry is short for ActiveValveControlSystem.

The name of VVEL Nissan.

The name of VVT-i and Toyota.

VVT, VC-the name of Suzuki Company. The former is used in cars and the latter is used in motorcycles.

The name of DVVT- Dafa car.

Smuri VT-the name of Mazda.

VarioCam, VarioCam Plus-the name of Porsche.

The name of VANOS, Valvetronic-BMW.

The name of TiVCT- Ford

Then there is the heavyweight feature. High energy attention!

As the fifth personality of the type 9 personality, how can it be over just by analyzing it? That’s the weight down there.

Number one!

The new EA888 cancels the 1.8T configuration. All are 2.0T engines. In fact, if you observe carefully. In fact, Volkswagen’s new 1.8T engine is exactly the same as 2.0T. Their diameters are all 82.5. What causes the poor discharge of this 200CC? The only difference between them is the stroke of the pistons. 2.0T is 92.8, while 1.8T is 84.1. In other words, you want to frantically convert 1.8T to 2.0T. Physically, you don’t have to expand the cylinder at all, but you just need to change the connecting rod and crankshaft in a set of crank-connecting rod mechanism. So this change can simply reduce costs, not increase costs.

The second point!

The new third-generation engine of the EA888 series, that is, the engine loaded on Tanyue. In the configuration bar of each website, there is no compression ratio in the engine bar. The important indicator of compression ratio for an engine is missing, in fact, strictly speaking, when we talk about compression ratio, we are talking about compression expansion ratio, because the compression expansion ratio of Otto cycle is the same. So the compression ratio is simplified in the engine parameters. Is it negligence? No, they can’t describe it in the form.

What is the compression ratio?

The following is from Baidu:

The minimum working volume of the cylinder, that is, the total volume above the piston when the piston is at the TDC, is called the combustion chamber volume, which is expressed by Vc, while when the piston is at the BDC, the total volume above the piston, that is, the maximum volume of the cylinder, is expressed by Va.

That is, ε = Va/Vc

The maximum compression ratio of a turbocharged engine is 11.65: 1. If the guess is correct, this official figure is also impossible at this stage, where the ratio of 11.65 to 1 should be the compression expansion ratio. In fact, this very high value should mean that the expansion ratio of the engine is 11.65 to 1. However, it is difficult for ordinary turbocharged engines to increase to the ratio of 10 to 1. Otherwise, the gasoline will be unstoppable detonation.

But in fact, the principle of Miller cycle is the same as Atkins cycle. It’s all compression ratio < expansion ratio. In other words. The BDC of that stroke of the engine compressed oil-gas mixture is not in the same position as that of gasoline deflagration expansion.

So the compression ratio of this engine is ε = Va (1) / Vc=9.6 ratio 1

The expansion ratio of workmanship is ε = Va (2) / Vc=11.65 ratio 1.

The new EA888 refers to the dual working state of the Miller cycle and the Otto cycle on the low-power version.

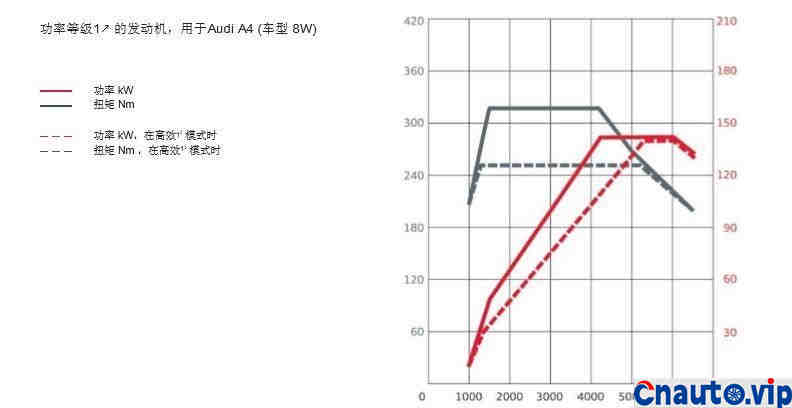

Later data also proved this point as shown in the figure.

The above is Audi’s data, and if Tanyue and Audi use the same, it is a variable engine. In your economic model, the book data of this engine should be 250 Nm, with the same power of 140 kilowatts.

To put it in a fashionable way. Have you seen the sixth-generation aero-engine studied in the United States? Some people call it a variable cycle engine or a variable cycle jet engine, and this cool techs has the same purpose as this engine in reason, that is to say. At low power and high power output, the engine shows different characteristics.

Then the economic model is not controlled by simple throttle sensitivity at all, but the higher order is two cycle modes.

So here comes the question. What is Miller cycle and what is Otto cycle?

In fact, the Miller cycle and the Atkins cycle have the same reason and purpose. That is, the compression is less than the expansion ratio. The advantage of this is to improve fuel efficiency.

For this reason, the rice version has been introduced in “Why small-displacement turbocharged engines become a trend”. For the Atkins cycle, please see the rice version: page link

In fact, the Miller cycle is very similar to the Atkins cycle. The early Atkins cycle depends on the linkage mechanism. In the modern sense, the Atkins cycle closes the exhaust valve late, while the Miller cycle closes the intake valve early. Their results are exactly the same. It is the purpose of compression ratio < expansion ratio.

Advantages

By changing the valve opening time, that is to say, increasing the expansion ratio, the non-throttle load adjustment can be realized, which greatly improves the engine efficiency.

Reducing the compression ratio can reduce the emission of nitrogen oxides in the waste gas.

The inflation temperature is very low.

Combustion has improved.

Finish the point. Let’s talk about both.

Actually, I have always had a point of view. On this evolved version of EA888. Volkswagen is not the developer of technology, but the aggregator of technology.

For example, through the dual injection system to reduce the problem of carbon accumulation in the direct injection system. (the double injection used by Toyota earlier)

That is, Volkswagen’s mature MPI and FSI dual injection system.

For example, improve engine performance by significantly reducing internal resistance (Mazda’s Chuangchi blue sky part system)

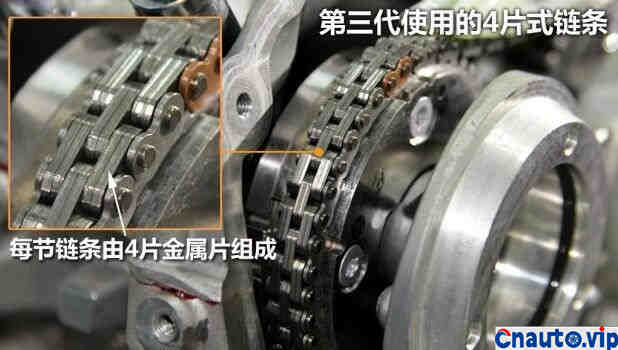

A three-piece oil scraping ring is used. Reduce internal resistance. And the width of the chain is also reduced.

Effective thermal management system. For example, the design of integrating the exhaust manifold on the cylinder head. This kind of design will become a trend of the design concept in the future, and its advantage is that the coolant heats up quickly during the cold start of the vehicle, thus shortening the hot car time. This does not seem to be particularly intuitive, so the benefit that passengers can feel intuitively is that the warm air from the air conditioner in the car can come faster in winter.

More importantly, the old problem with EA888. The two-stage oil and gas separator has been replaced. In this way, the management of oil is more effective. You know the old driver. I dare not say to put an end to this completely for the time being, but the hat of “burning oil” is definitely going to lose the engine.

So much for the interpretation of EA888. Do you understand it?

If you want to understand or discuss technology together, please pay attention to Coldplay T tribe, or you can scan the QR code below directly, which will send major benefits from time to time!

April 1, 2024

April 1, 2024  March 27, 2024

March 27, 2024

March 27, 2024

March 27, 2024