MINI 3 cylinder inexplicably shaking and flameout-Troubleshooting

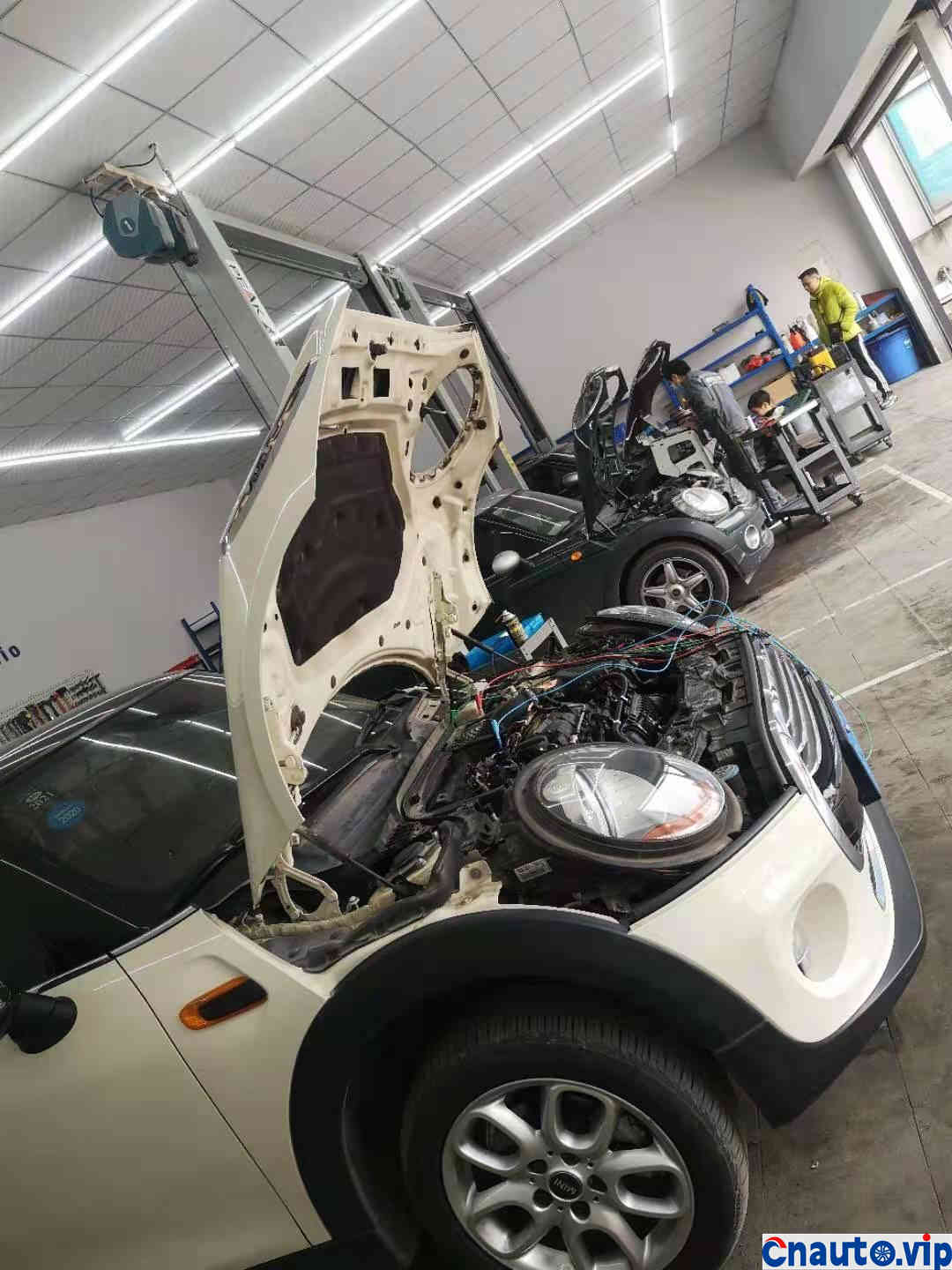

There is a fault of abnormal jitter of a BMW Mini three-cylinder engine in the store. I am the third repair shop to take over. The fault phenomenon is that the red light vehicle occasionally shakes seriously or even stalls, and there is nothing abnormal when the vehicle starts again. Read the fault code and have the fault record of flameout. This vehicle has replaced the crankshaft pulley in the first store, replaced the injector, spark plug, the fault is still not solved, and the belt rotation is still a sub-factory goods, the original wheel is not broken, I do not know how many meanings. Car friends can not go to the 4S store repaired for a week and changed a set of fire, thought that the result just out of the 4S store 20 km fault appeared again. It means that the fault has not been eliminated. Under the introduction of a friend, the car friend found us. When I learned about the situation, I found that the work was not so easy. It took us a little more time to check the problem. It took us about 5 days to repair the problem. Because there was not much time during the day, we only found the fault point at night. Finally, we found the fault and succeeded in troubleshooting it. Share-do not reprint without the permission of the original work![]()

Both of these minis are jitter faults, and the point of failure is unexpected.

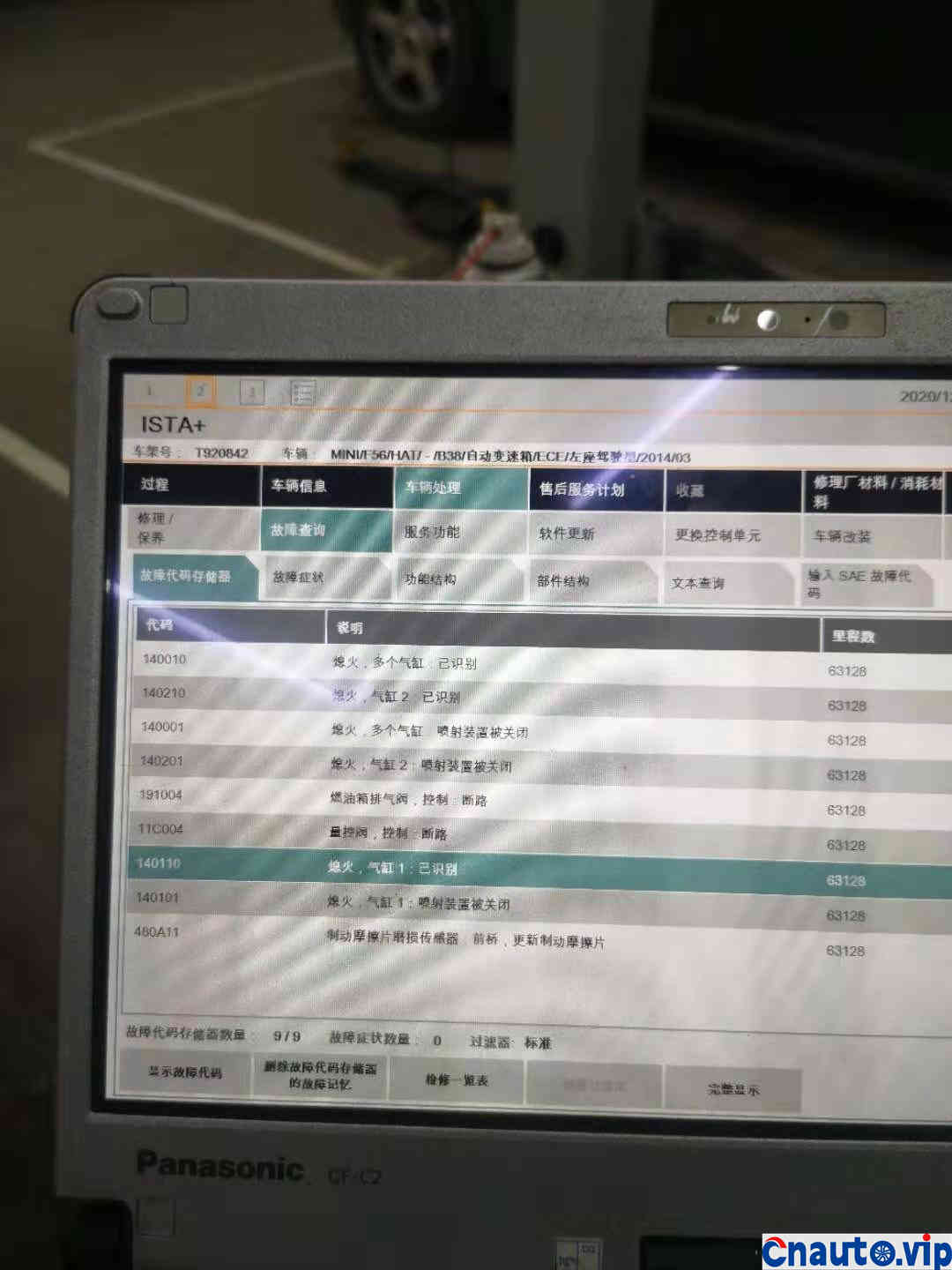

First of all, we connected to the computer to read the fault records, and went to the test drive, and found that sometimes the jitter is really serious.

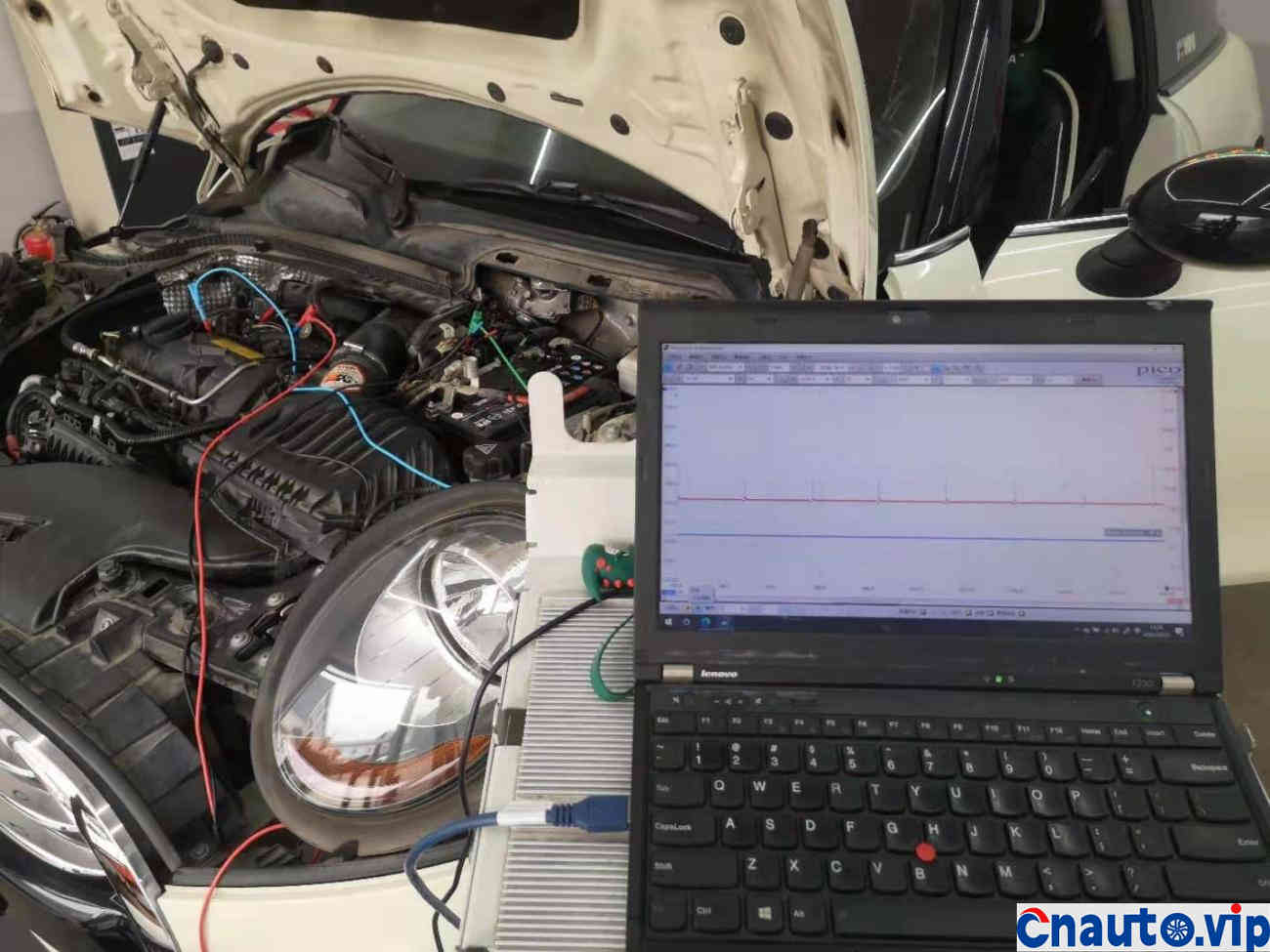

There is almost no need to check the vehicle jitter, and we need an oscilloscope to capture what happens to the engine in the event of a failure.

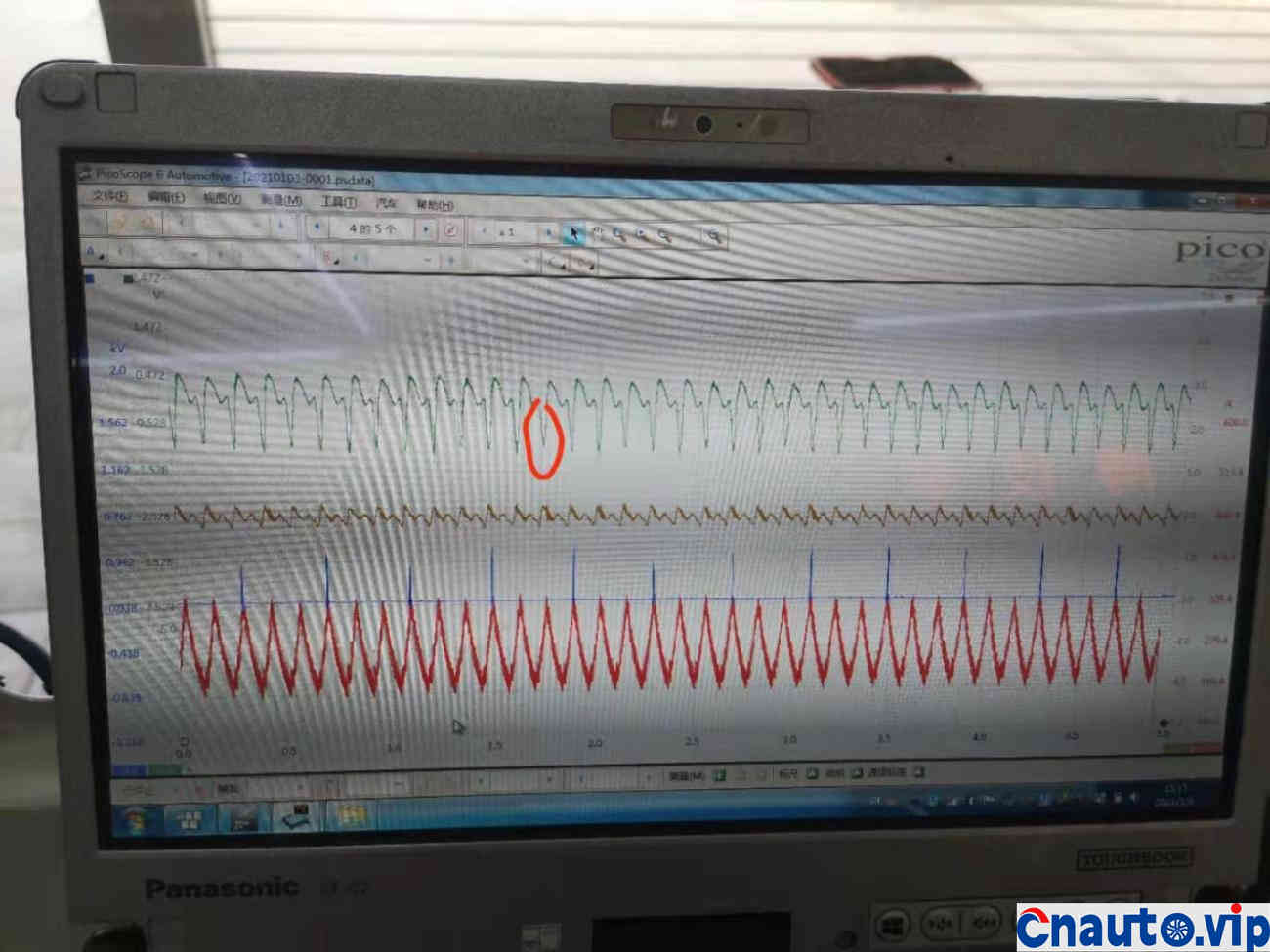

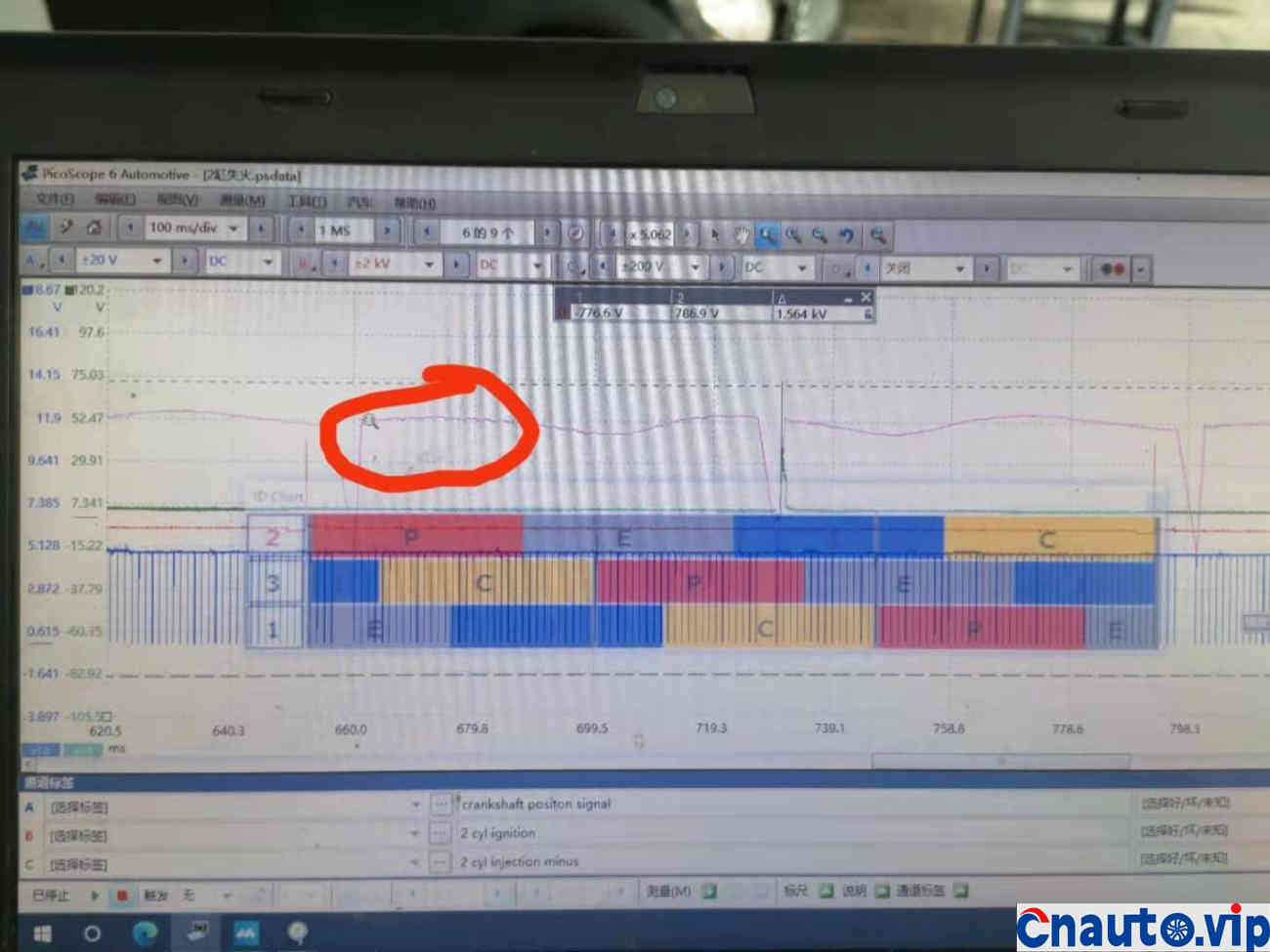

We connected the computer to the oscilloscope, and after a long test run, we found some faults that are invisible to the naked eye.

We found that the engine was sometimes very unstable and there was a serious fire.

At the same time of the failure, there was a serious shortage of air intake.

Two of the three MINI are challenging troubleshooting.

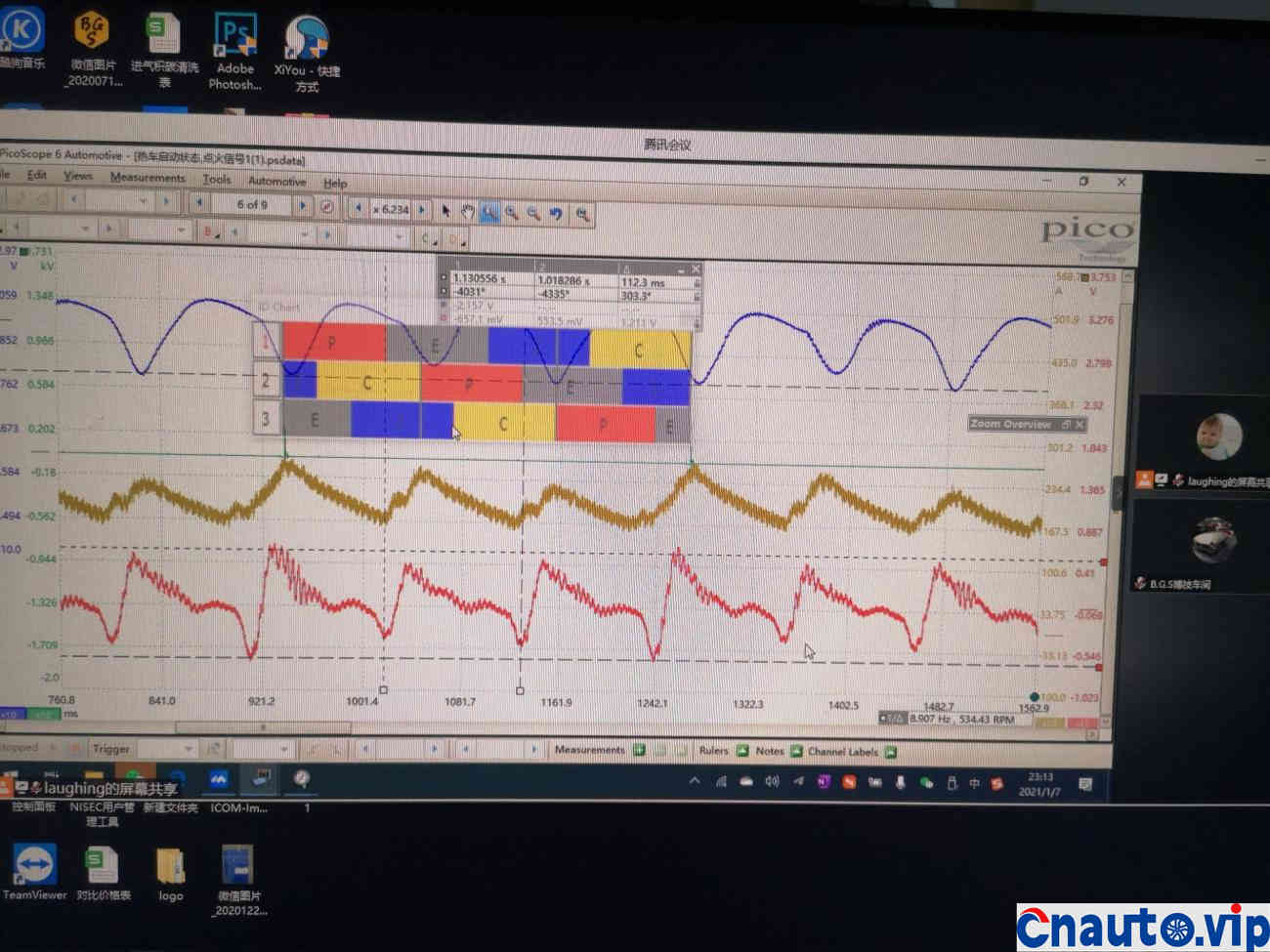

At night, we work overtime to continue to capture the frequency of the failure and the operation of each sensor and actuator in the event of a failure.

After several days of hard work, the suspected targets were ruled out one by one, getting closer and closer to the truth.

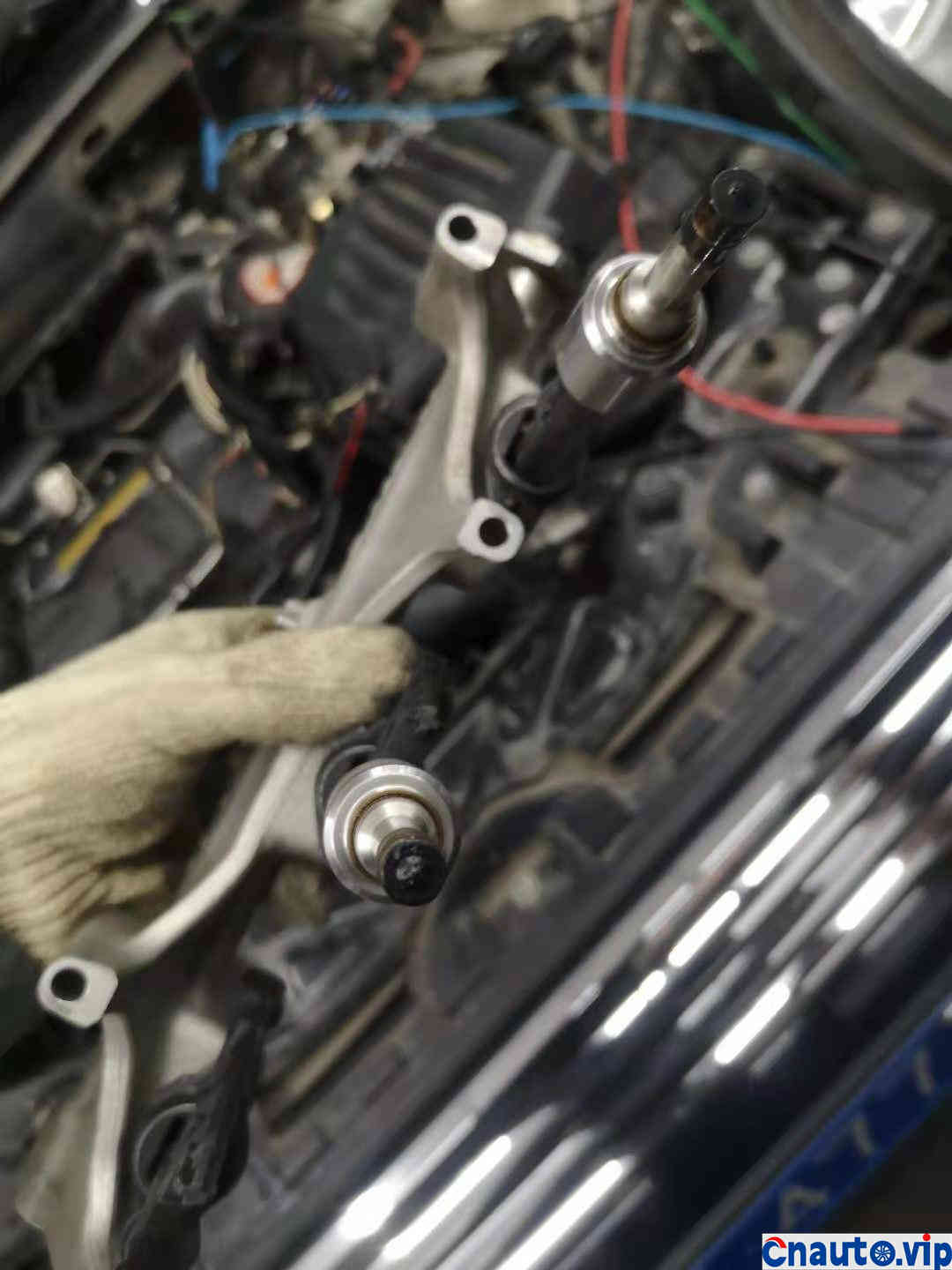

Spark plug removal

Fuel injector removal

We synthesize the data flow and the conditions under which the failure occurred, so we lock the target on the machine itself, and it takes a little courage to say that there is something wrong with the B38 machine itself. after all, the more meitative 4S stores dare not say that there is something wrong with the machine. we are about to prove whether our conclusion is correct by dismantling the engine.

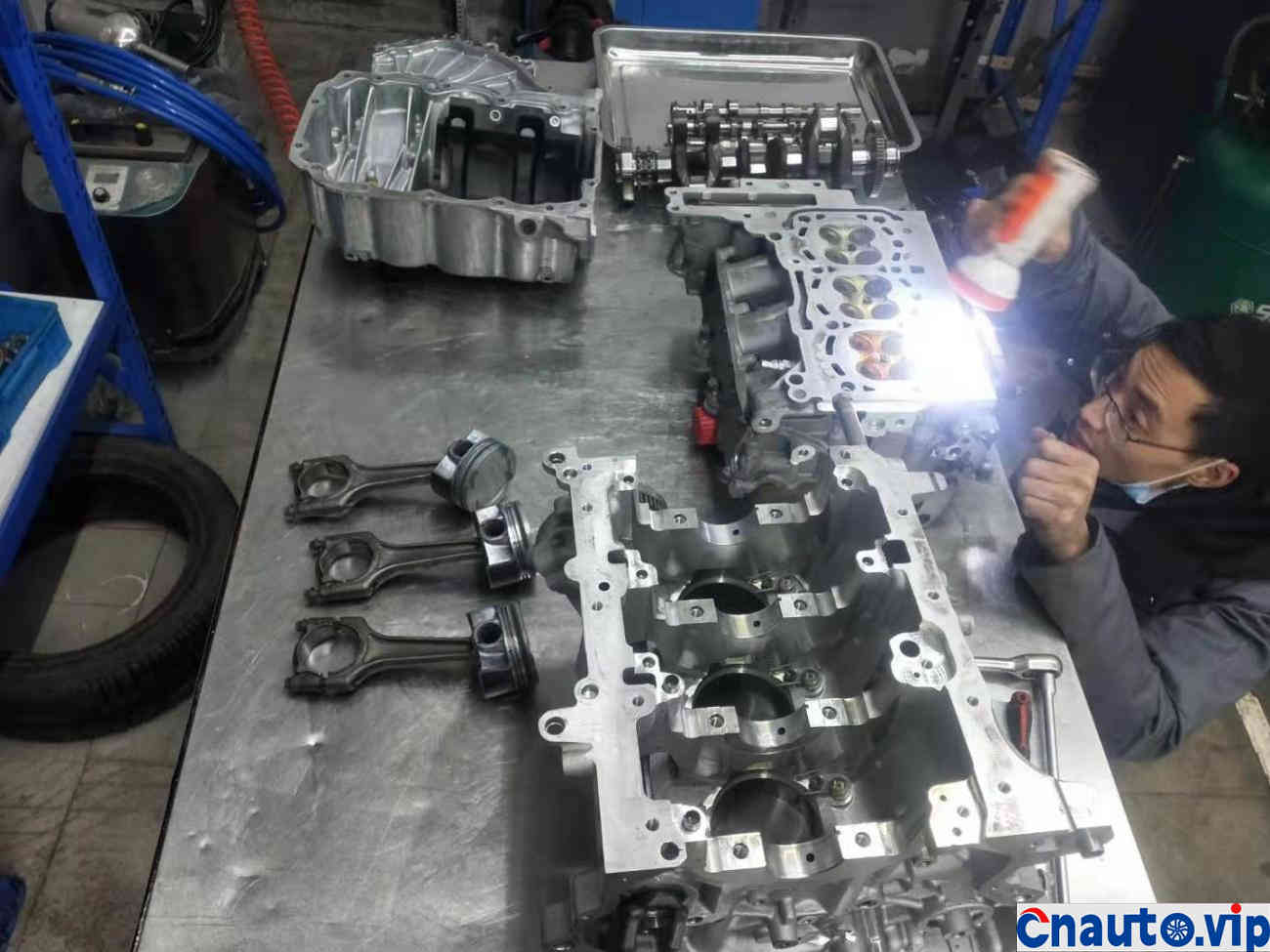

We dismantled the engine after half a day.

Then we break down the engine and find out.

Watching the powertrain decompose step by step, the answer is about to be revealed.

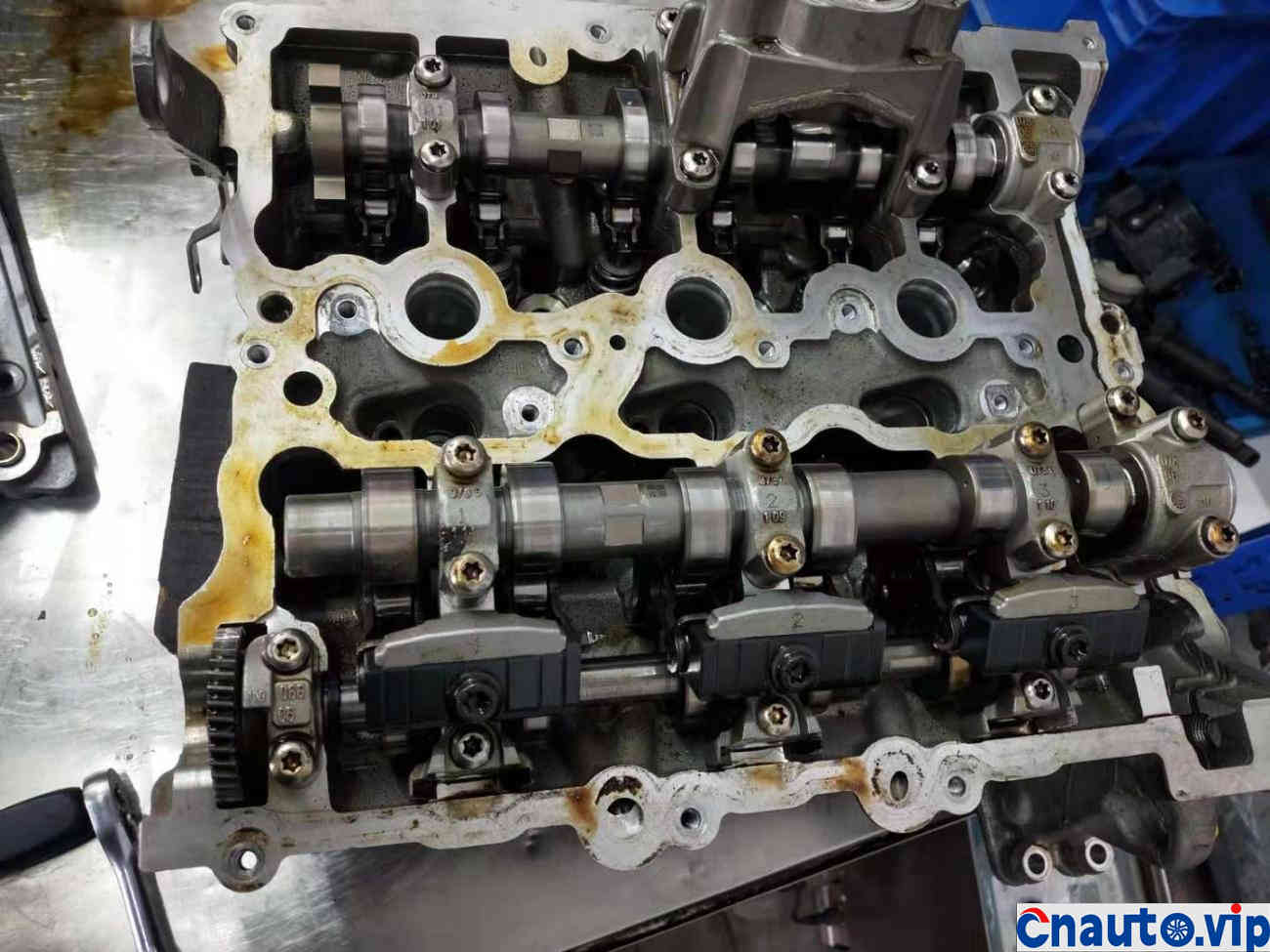

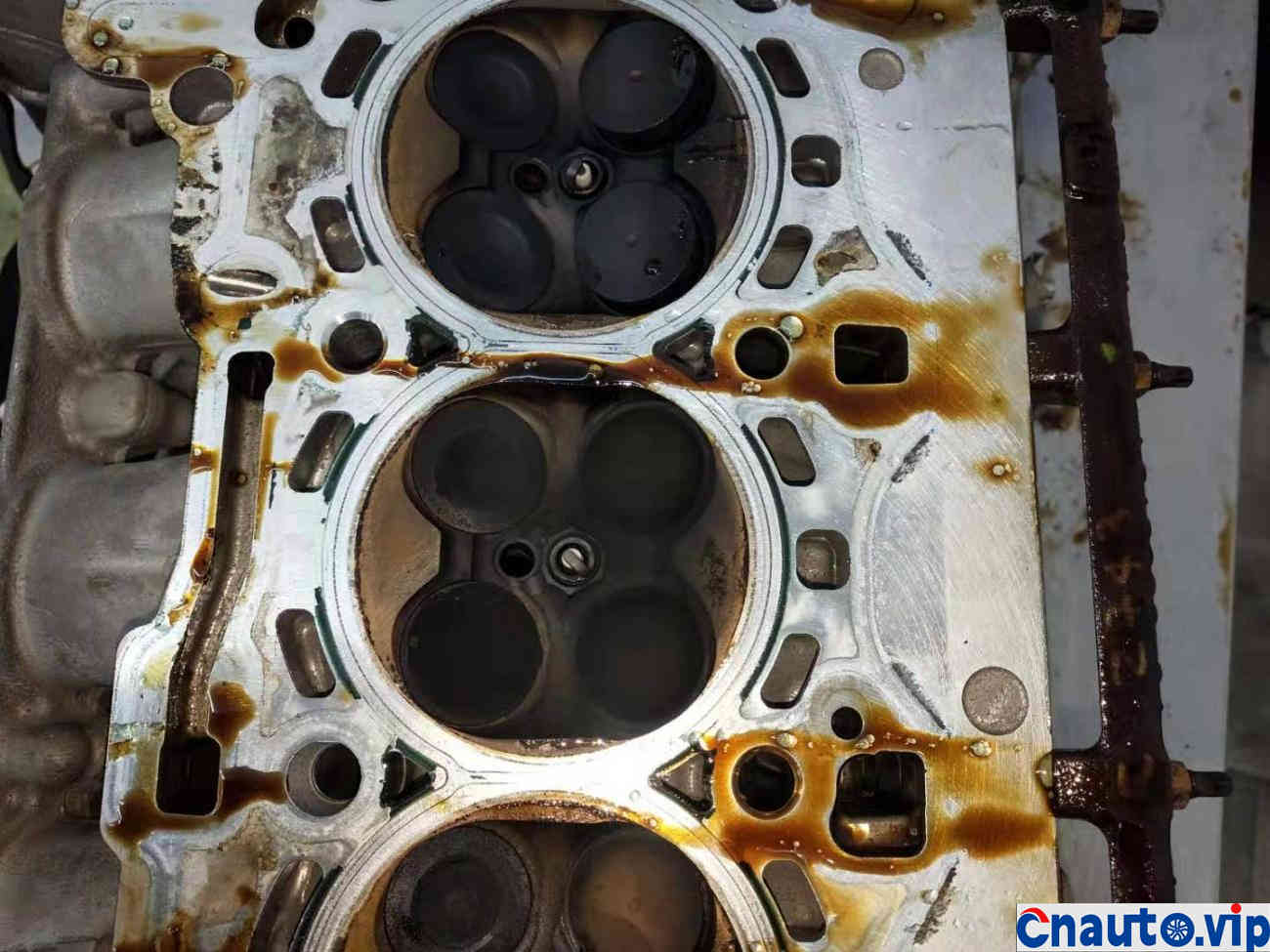

Soon we unloaded the cylinder head.

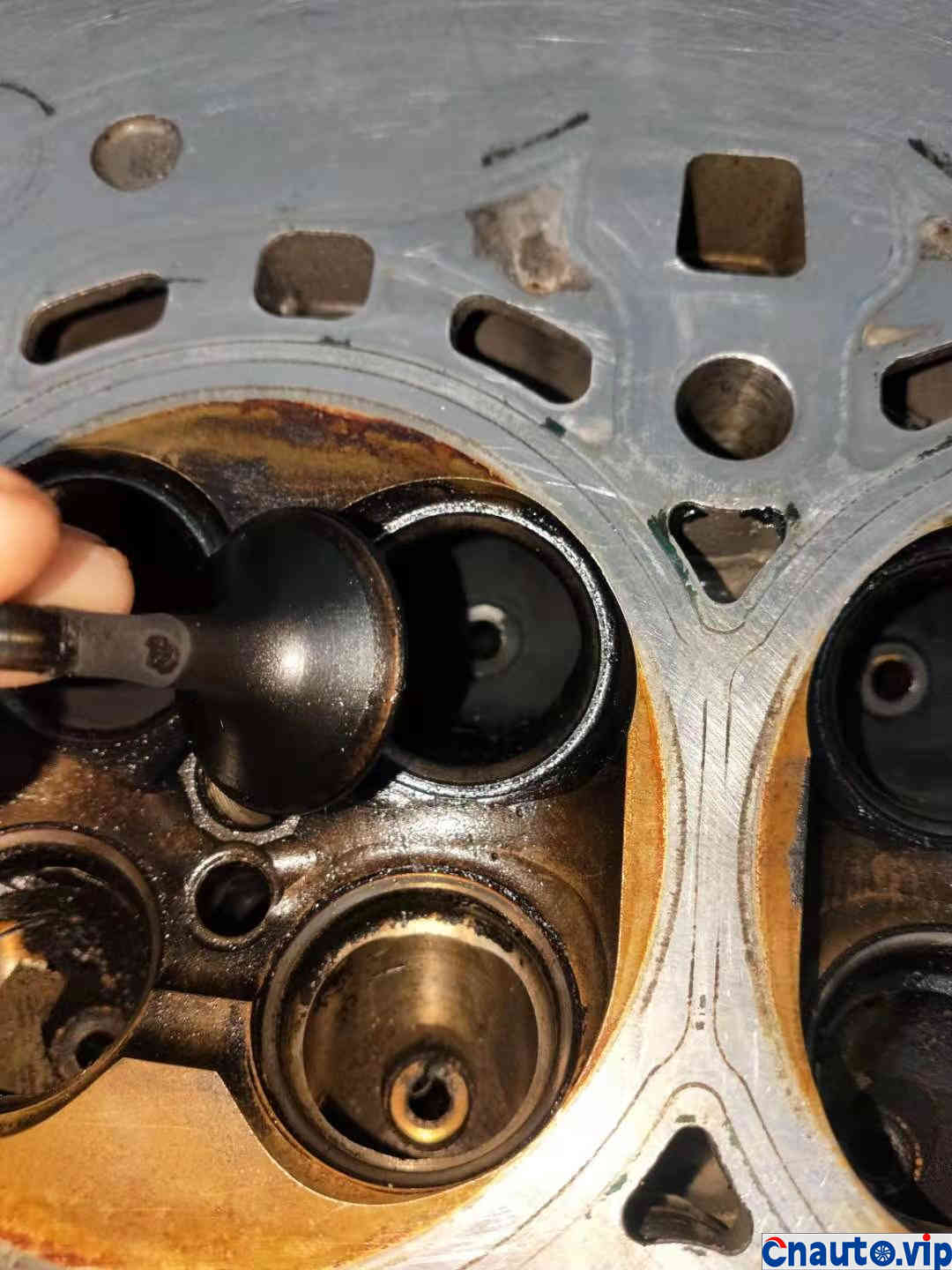

Find the first point of failure

The car didn’t burn enough.

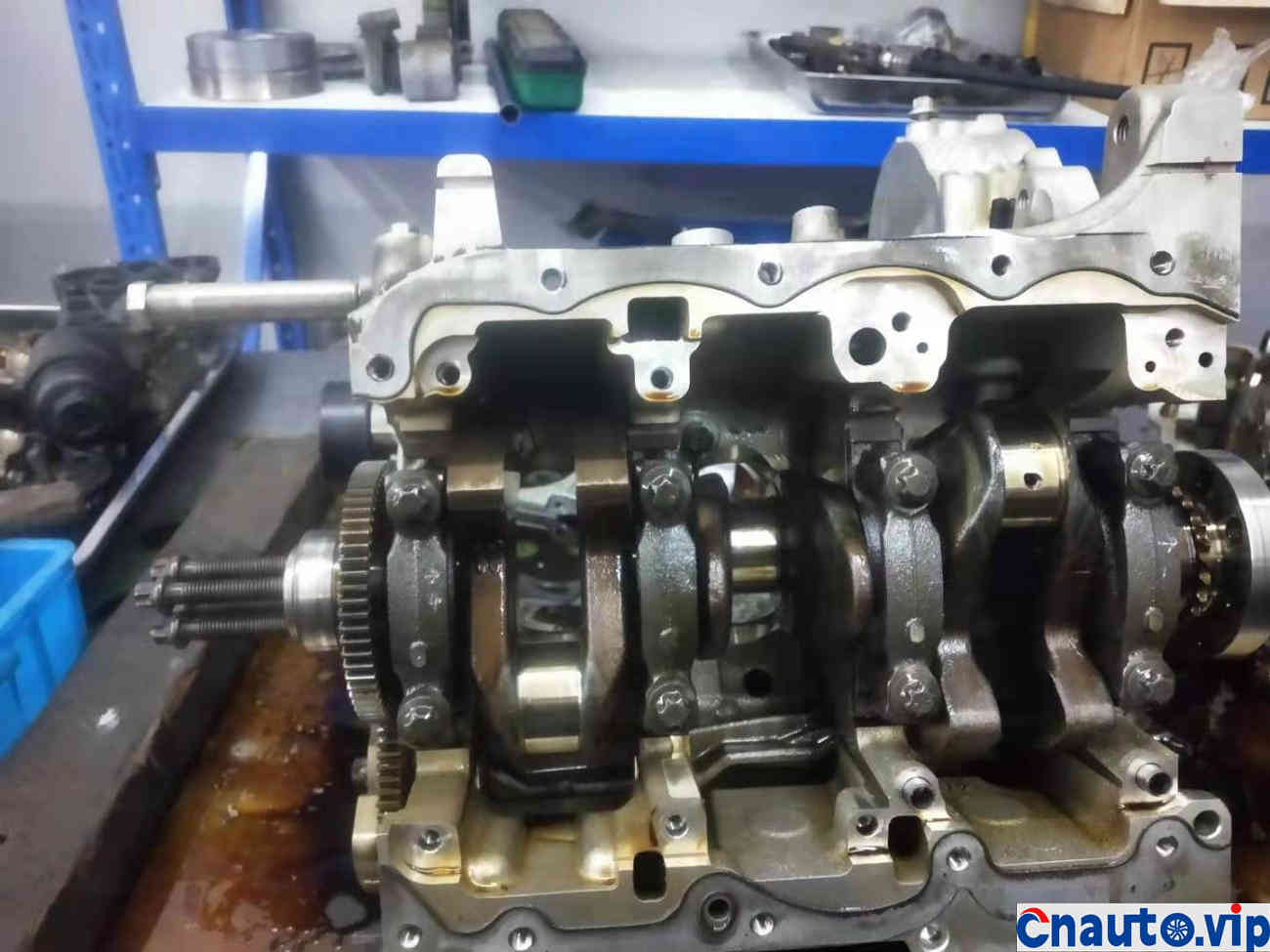

Then remove the piston.

We found that there is a serious series of air in the piston, and how can the three-cylinder engine run smoothly in such a bad condition?

We completely disassemble the engine, reassemble it, and replace the parts that have problems with grinding.

Re-grind the valve and check whether the clearance meets the requirements.

Check for leaks.

Check the plane of the cylinder.

Check the wear and tear of the cylinder to see if it meets the requirements.

Reassemble the engine and install the oil injector.

The stationarity of a three-cylinder vehicle is very important.

Reinstall the crankshaft to replace the parts that need to be replaced

Install the lower middle section of the engine.

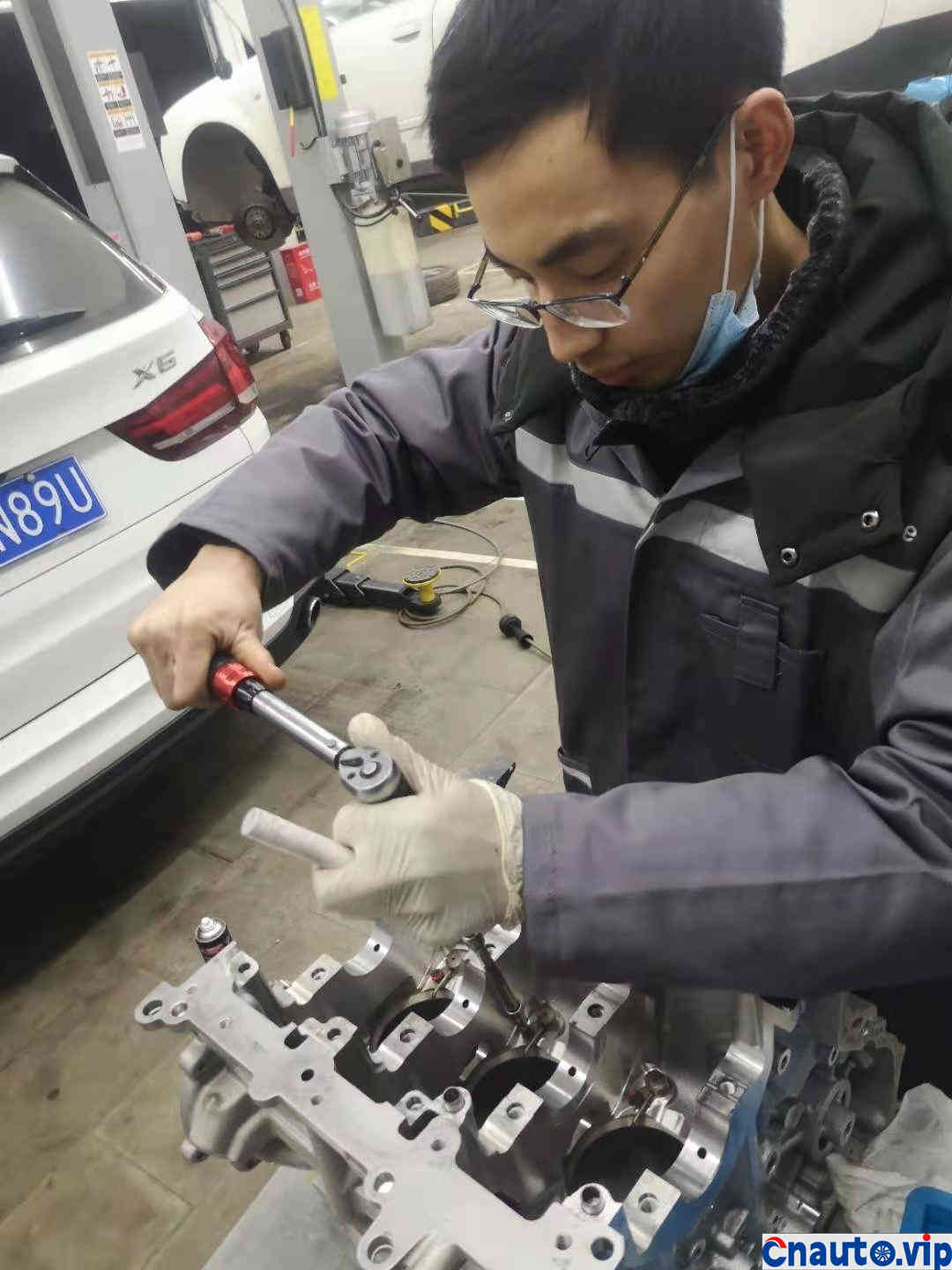

Fastening connecting rod bolt

Check the installation again.

Install the chain and timing mechanism.

Grind clean valve.

Install the valve mechanism.

Install oil pump and timing mechanism.

Check again.

Replace the brand new guide rail.

Replace the brand new cylinder gasket seal.

Recalibrate the timing mechanism.

Install timing sprocket.

The engine gearbox fits.

Tighten the connecting bolts.

Wiring harness.

Tighten the transmission bolts.

Then install the engine on the body. Verify that the fault still exists.

After two days of commuting to and from the road test, the trouble is completely eliminated.

The vehicle will be delivered in the evening.

The small white MINI fault repair has been completed, and finally there is no need to worry about flameout.

Hot Information

Tesla Autopilot and similar automated driving systems get ‘poor’ rating from prominent safety group

April 1, 2024

April 1, 2024 Localization of EV parts without production scalability may not help cut EV price, says President, Amara Raja

March 27, 2024

March 27, 2024

JCTSL may turn bus stands into charging points for e-buses

March 27, 2024

March 27, 2024 You May Like