If riders feel that seat adjustment is stuck, you can come and read this article.

The seat is mechanically adjusted, and the mechanical seat rail is convenient for maintenance.

Sometimes when Langxing adjusts the front and back of the seat, the adjustment feels stuck, and the phenomenon is that it cannot be pulled up.

Compared with the co-pilot, there may be some problems with the mechanical structure of the seat in the driving position, so come to the store to check it.

4S has enthusiastic after-sales service and directly said that if there is any problem in the inspection, you can claim for replacement. I said I would try to check it first, but it might be a minor problem.

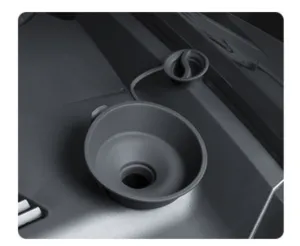

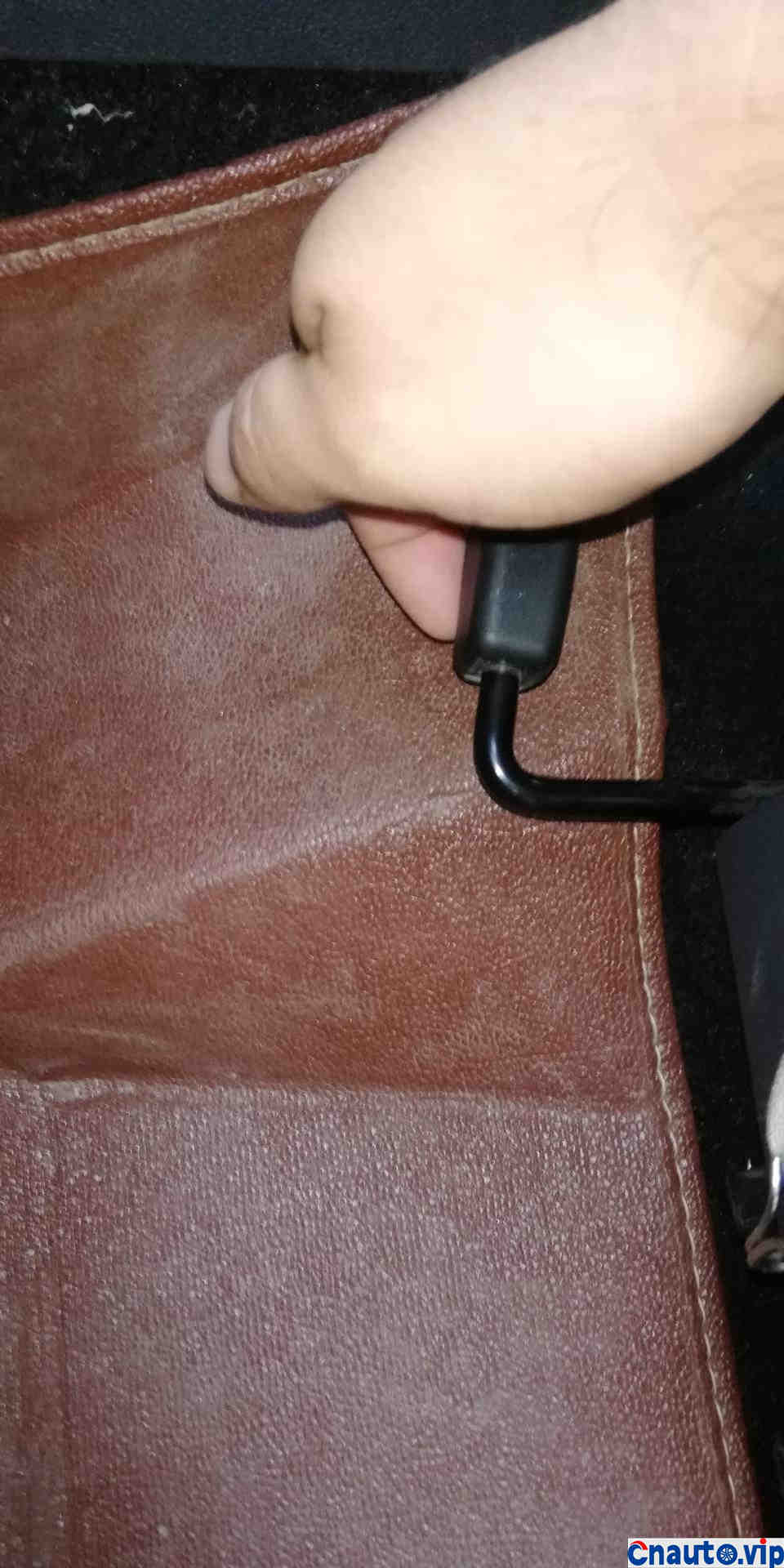

I can’t lift this place. It’s a bit jammed. It seems that sometimes the seat is not adjusted in place back and forth.

I checked it myself and found no abnormalities. I still need a professional teacher to check it.

This needs to be checked in the sheet metal workshop. After the after-sales service, he drove directly there.

After driving after the sales, I took photos.

We drove to the sheet metal workshop and waited for the instructor to come and inspect it.

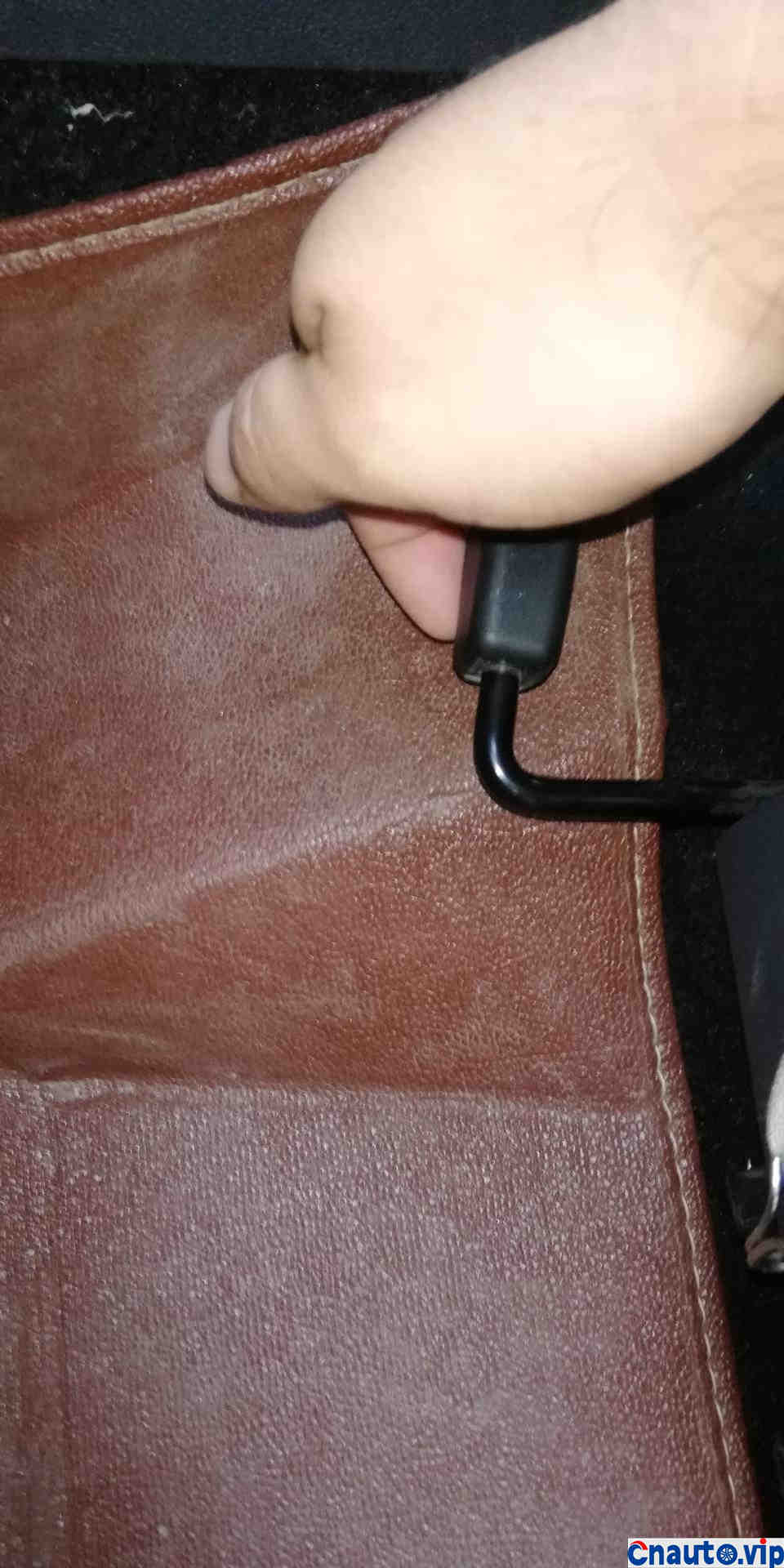

The master pushed the seat back and forth a few times, but it seemed that something was wrong and something was stuck.

After moving back and forth a few times, something might get stuck on the guide rail. I broke it back and forth vigorously several times, hoping to get rid of it.

The master was checking for what stuck on the guide rail and took out the mat. The assistant factory mat I gave when I bought a car is ready to be replaced after a while. The division looked for the foreign object, but couldn’t find it.

I also checked and found no other foreign objects.

It is also possible that the guide rail is stuck. After all, it is a mechanical part that greases the guide rail.

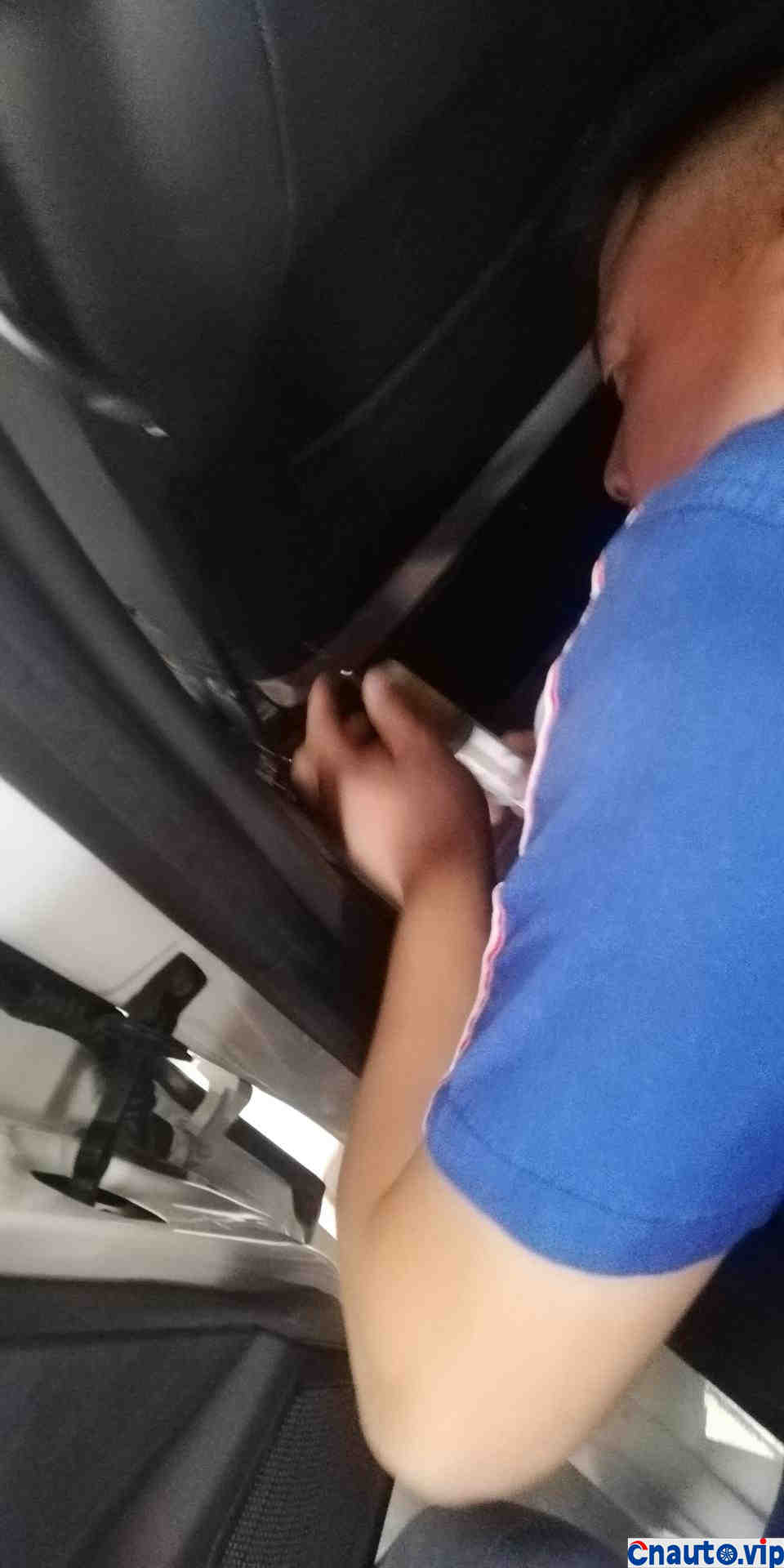

The front and back of the guide rail must be oiled, and the master carefully applied it with the oiled needle tube.

Not a single structural part was missed, and it was all oiled.

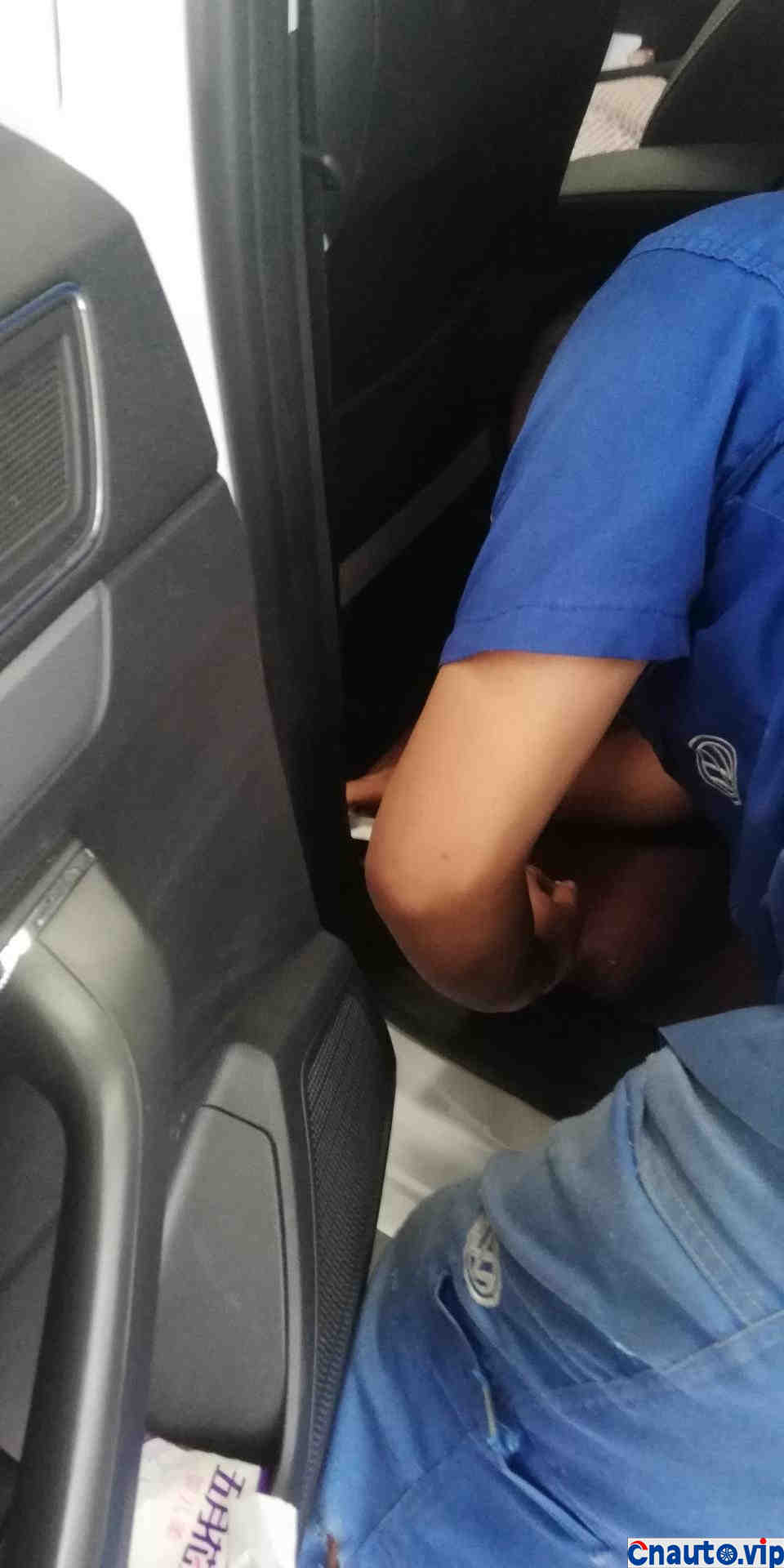

This place is quite difficult. After all, it is under the seat. It is troublesome to remove and it is a little difficult to oil. The master is really dedicated and maintained this position for a long time.

A needle tube with a needle, this master is giving an injection to the car. I hope I can cure my stuck problem.

Finally, the master tried it again, and it seemed that it was getting better. Use it first, and it would not affect the use.

Give a close-up of the hard-working master. Close-up clothes and tools. People will not take pictures anymore to protect privacy. Many hard-working front-line maintenance workers, like this master, are not afraid of dirty and tiring work.

The master also helped inspect other structures that needed oiling.

Oiled the hinge and limiter of the door. This can prevent abnormal noises.

All three door connection points have been lubricated.

After the inspection, I came to wash the car. Car washing was good. There was an automatic car washing machine in the shop. One step and two minutes to wash.

After washing the car, it is completely new and beautiful. Ready to go home.

April 1, 2024

April 1, 2024