Do it yourself to repair the trunk cover support shaft

At the beginning of the year, Toukai has been taken care of. Who would have thought that in May, I found that the trunk cover support shaft was cracked. I thought it should not be within the warranty range and it was not a big deal. I just had to find a way to repair it myself. Unexpectedly, it took a lot of trouble. Now I will share the maintenance process with all motorists for reference. If you encounter the same situation in the future, you can avoid taking some detours.

When putting things in the trunk, I found that the left trunk cover support shaft had been peeled off. I wanted to lift the cover up to see clearly, but I didn’t expect it to just tear it open.

I took off the cover plate and took it home to study it. I wanted to use an electric drill to drill holes and screw the cover plate and support shaft, but I was afraid that it would affect the appearance.

The surface of the trunk cover plate is covered with a layer of material similar to fleece. The rubber supporting shaft is made of hard plastic. You can see that there are traces of glue on the surface of the supporting shaft, and the fleece on the cover plate has been stained. I feel that the characteristics of the fleece material are not suitable for bonding. If they are subjected to certain external force, both will be peeled. The manufacturer’s design result should not be comprehensive enough.

With my own judgment, I found tools to clean up the residual glue on the hard plastic support shaft.

To be honest, the quality of the glue used by the manufacturer is really good. It takes a lot of effort to clean it. It took nearly an hour to clean the surface of such a big thing. It was really cleaned bit by bit with a wallpaper knife.

In pursuit of perfection, I wanted to clean the surface very thoroughly, but my fingers had objections.

Ordered a set of hot melt adhesives online.

Prepare for construction.

Glue the surface of the supporting shaft.

I used a wallpaper knife to slightly clean the fleece on the corresponding position of the cover plate to avoid falling off after secondary bonding. At the same time, I also applied glue and fixed the two by hand for a period of time.

Facts proved that the hot melt adhesive had no effect. If it was not adhered, the hot melt adhesive on the surface of the support shaft could easily be torn off, and the first battle failed.

After making do with it for a while, I came to the 4s store to do the first insurance in June. I talked to the after-sales technician about the situation, replied it was a small matter, and took out 502 to help me bond it for free.

It turned out that the two were still stubborn and could not get along well, and their efforts failed again.

I still want to thank the Aika Forum. I chatted privately with the car friends I met in the forum and gave me advice that I could use engineering structural glue.

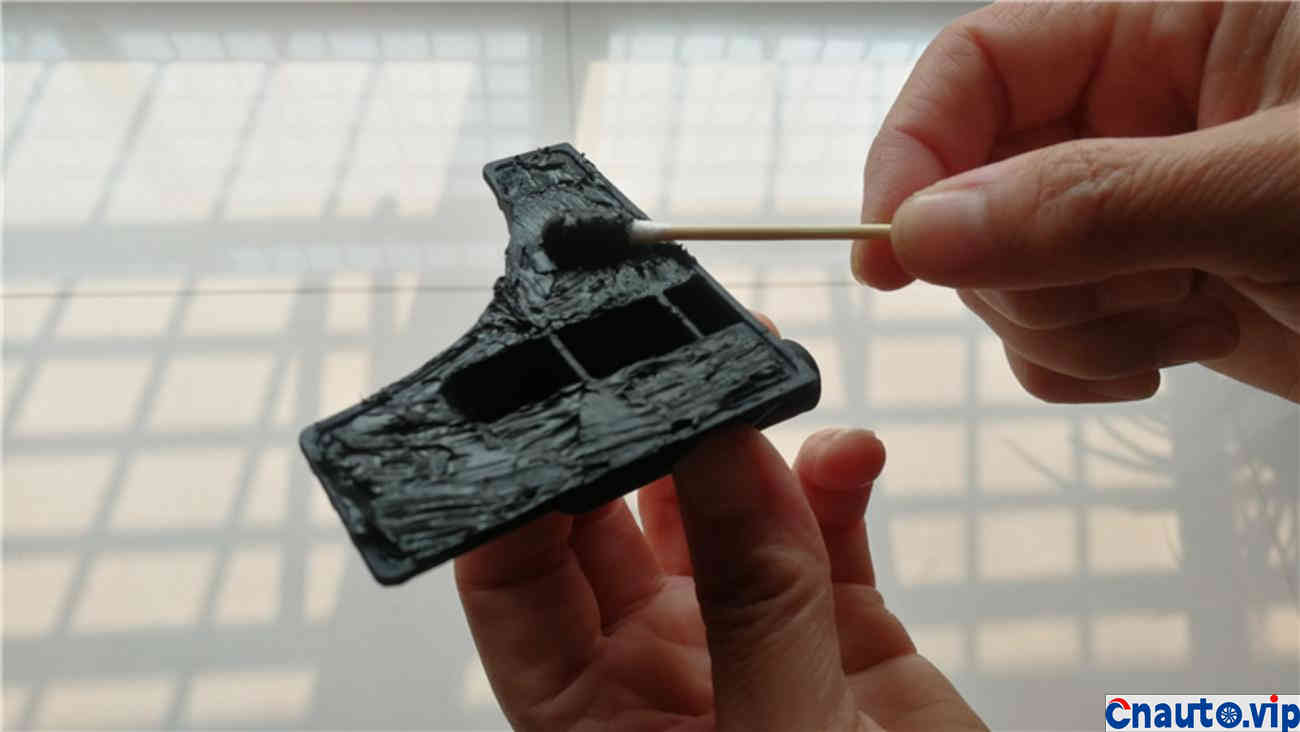

I specially bought black structural glue and applied it evenly with a cotton swab on the surface of the supporting shaft.

Apply some accordingly on the cover plate.

I specially found a very heavy big nut from my work and pressed it and fixed it for more than 24 hours. It is worth celebrating. After trying it, I couldn’t pull it off. The two are finally together happily again.

Properly installed, the trunk cover opens and closes freely, perfect!

Hot Information

Tesla Autopilot and similar automated driving systems get ‘poor’ rating from prominent safety group

April 1, 2024

April 1, 2024 Localization of EV parts without production scalability may not help cut EV price, says President, Amara Raja

March 27, 2024

March 27, 2024

JCTSL may turn bus stands into charging points for e-buses

March 27, 2024

March 27, 2024 You May Like