[Tractor DIY] Optimize pipelines and move towards standardized cabins

A while ago, in order to prevent the waste valve of the old car from breaking down on the road due to cracking and leaking due to being too old, he simply made a renovation and bought a corrugated pipe for direct connection. The original heating function was abandoned. After using it for a while, the effect was OK. There was no abnormality in driving, and there was no problem of missing coolant. But they are all fixed with cable ties. Firstly, they are afraid of being damaged by heat after using them for a long time. Secondly, they are not aesthetically pleasing. I still like the original factory standard style. Recently, we have obtained some pipe clamps and straight pipes and are ready to further improve and standardize them.

It is this type of pipe clamp, as well as straight pipe, that is used for further specification.

One end of the straight pipe is 8, but I didn’t pay attention to how much it is at the other end, because I only need an 8 at one end.

The pipe clamp is an original accessory product and is used to fix 2 pipes and keep them at a distance.

One end is a buckle design, which is very clever.

The other end is an opening card.

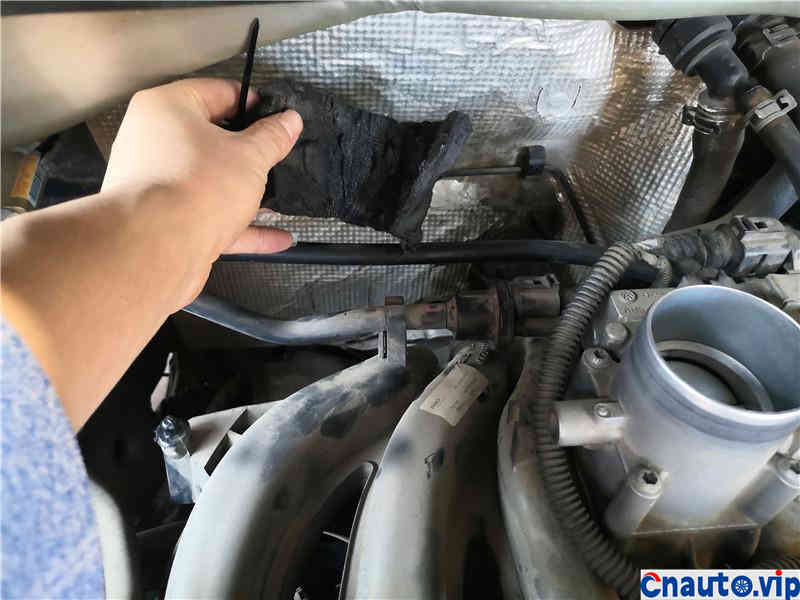

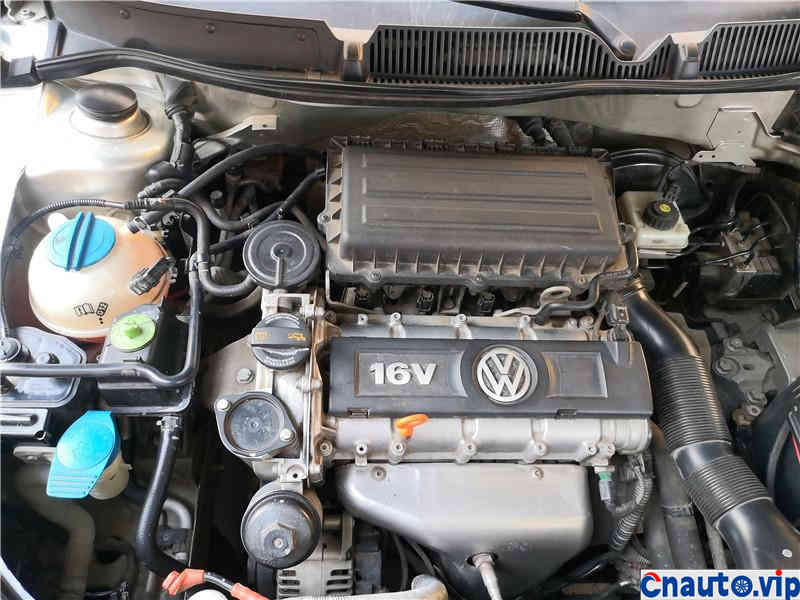

Open the engine compartment.

The original abandoned pipe was still in its original position and was not damaged. I stuffed it with a tissue for fear of getting dirty things in. I considered that if I needed it in the future, I could restore it at any time.

Prepare to use this straight pipe to plug it against dust.

Exactly match, haha.

After trying to match, one end was sealed with a hot melt gun.

It’s simple, just seal it off so that dust cannot enter.

The air filter assembly was opened to expose the complete transformation.

After thinking about this period, I also wrapped it with hot-air cotton and fixed it with the tie. I used it first because there was a lot of stress on this side, and I wrapped it more comprehensively, and the tie straps were alternately wrapped, which was very firm.

The place where it is fixed with the carbon cylinder valve is the key that needs to be changed. After all, this method can work, but it is not convenient to replace the parts in the future.

Remove wrapped insulation cotton and cable ties.

Prepare to replace it with pipe clamps.

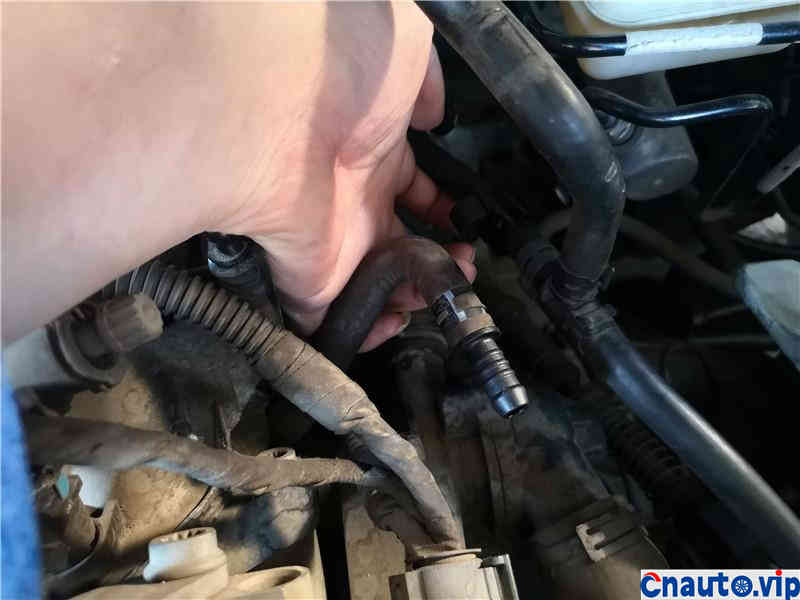

One end of the pipe clamp is fixed on the carbon cylinder valve pipe.

Tighten the pipe clamp.

In addition, the modified pipe is fastened into the pipe clamp.

This is in place and provides a good fixation and separation effect.

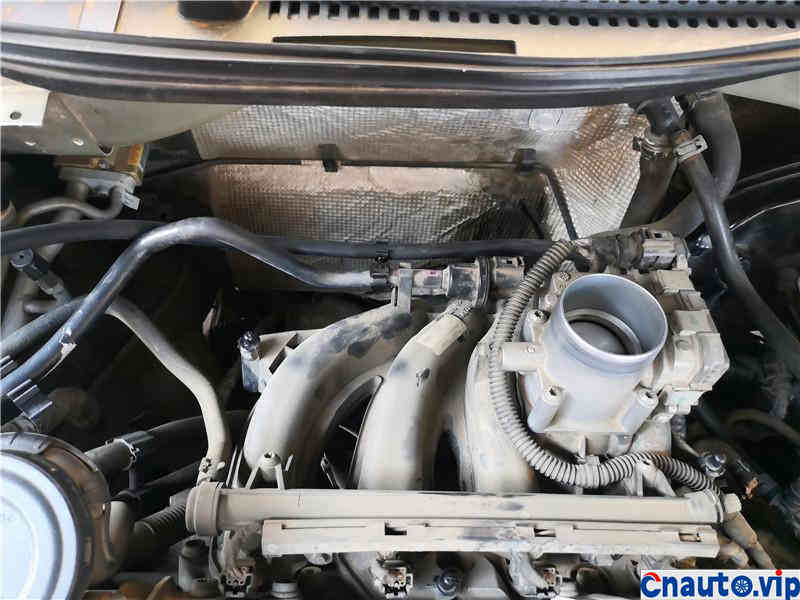

Looking at it from a distance, it is more standardized.

The original pipe on the coolant side is empty like this, shaking left and right, and it also needs to be fixed with pipe clamps.

One end of the empty pipe is plugged into a sealed straight pipe to provide a shielding effect.

Then fix it with pipe clamps.

This section also requires pipe clamps.

It’s a good match. It’s good.

It turns out that those connected to small antifreeze water pipes also use direct shielding.

To avoid shaking, also use pipe clips to fix it.

OK, after further renovation, although the functions of the original car are abandoned, they can be restored immediately with a pair of pliers.

After further improving the specifications, the hidden danger that the original pipe may shake in the engine compartment for a long time has been avoided. At the same time, it is ready for recovery at any time in the future, transformation and subsequent perfect integration are made.

Hot Information

Tesla Autopilot and similar automated driving systems get ‘poor’ rating from prominent safety group

April 1, 2024

April 1, 2024 Localization of EV parts without production scalability may not help cut EV price, says President, Amara Raja

March 27, 2024

March 27, 2024

JCTSL may turn bus stands into charging points for e-buses

March 27, 2024

March 27, 2024 You May Like