The method of high-speed Weng sound detection and bearing replacement of “Lao Cai talk about Subaru”

Recently, Lao Cai has been busy moving, and I don’t have much time to go online, but I often open it and have a look at it. The old account is suspended, and I will post a new post later or follow this number with all my car friends. At the same time, in order to serve the majority of Subaru cyclists, Subaru specially moved the Subaru specialized alliance (Zhengzhou shop) to the new store. recently, many motorists have privately consulted about the bearing problem, how to judge whether it is good or bad, how to replace it, and how to avoid abnormal bearing noise to prolong life, and so on. In order to prevent the majority of riders from taking detours to replace bearings and spend more money unjustly, recently there has been a vehicle replacement, and by the way, the replacement process has been sent out.

??? Bearing (Bearing) is an important part of contemporary mechanical equipment. Its main function is to support the mechanical rotating body, reduce the friction coefficient (friction?coefficient) in the process of motion, and ensure its rotation accuracy (accuracy).

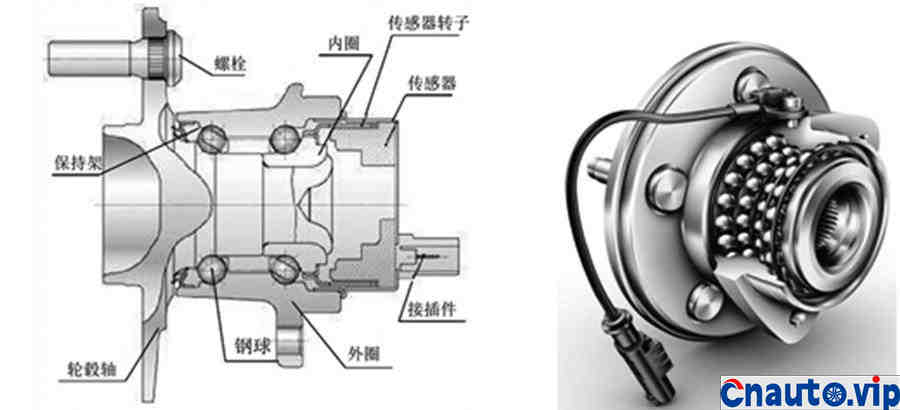

According to the different friction properties of moving elements, bearings can be divided into two categories: rolling bearings and sliding bearings. Among them, rolling bearings have been standardized and serialized, automobile four-wheel bearings generally use rolling bearings, rolling bearings are divided into three types, the first type of tapered bearings (currently continue to be used in buses or trucks,) the second kind of integral bearing, internal and external pressing integrated, (some low-end vehicles are used) the third kind of bearings, which is also the most commonly used bearing in Subaru at present, including flower basket integrated bearings. The third kind of bearing has many advantages, such as direct pressing by manufacturers, high precision, good sealing, convenient and fast installation, long service life, etc., disadvantages need to be replaced assembly, noise can not be opened for maintenance, cost increase and so on. The following are three types of long-term bearings

The top is a tapered bearing, which is currently mostly used for large trucks and customer wheels.

The second generation of outer raceway has a flange for fixing the bearing, which makes the maintenance of the car easy.

The third generation hub bearing is designed with inner flange and outer flange, the inner flange is fixed on the drive shaft with bolts, and the outer flange installs the whole bearing together and fixed on the axle.

How to check the bearing abnormality and the detection method.

When one of the four hub bearings of the car is damaged, you will hear a continuous buzzing sound in the car while driving. (similar to the sound of aircraft taking off). It feels like the whole car is filled with this buzzing sound, and the faster the car is, the louder it is. The following is the method of judgment:?

One: open the window to see if the sound is coming from outside the car. (the sound is most obvious at 80 kilometers per hour)

Second: after increasing the speed (when the buzzing is loud), observe whether the noise comes from the engine. If the buzzing does not change while taxiing, it is probably the wheel bearing.

Three: lift the car (release the handbrake and hang neutral before). When there is no lift, you can use jacks to lift the wheels one by one, and the manpower can quickly turn the four wheels one by one. When there is a problem with the car bearing, it will make a sound. It is completely different from other axles, and it is easy to tell which axle is defective with this method. ??

The above is a simple introduction and judgment of the bearing, the following is the replacement process

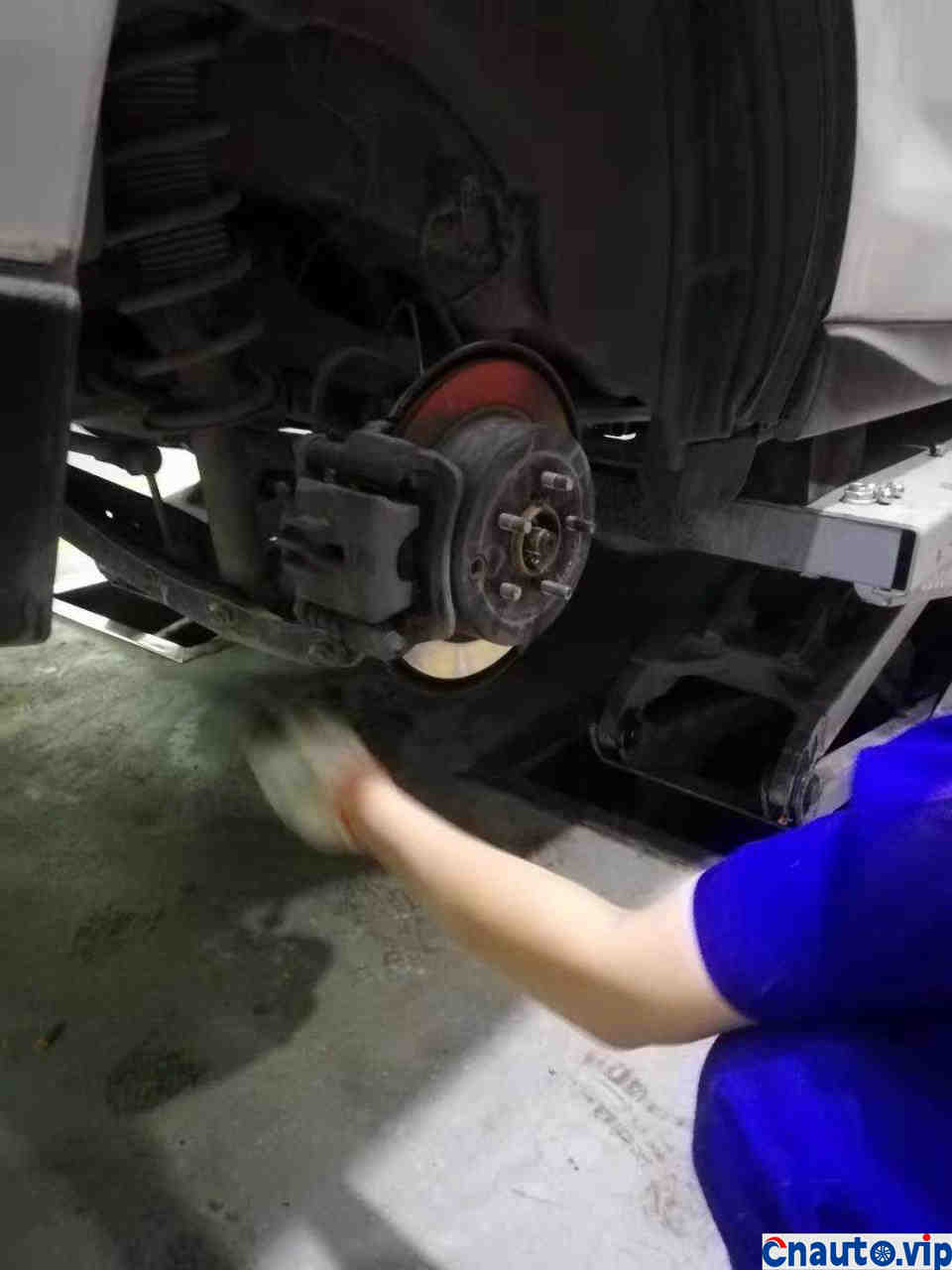

The vehicle lifts the vehicle steadily and removes the rear wheel.

With a screwdriver or small crowbar, reset the brake sub-pump. (open the brake master pump refueling cover and clean it in time if the brake oil spills over. The brake oil is corrosive to a certain extent. )

Remove brake sub-pump and sub-pump support

Remove brake sub-pump and sub-pump support

Send off the handbrake (if the ground is operated alone, cover the wheel before releasing the handbrake to prevent the wheel from slipping)

Take air on one of the 8 screws, push the brake disc out, and remove the brake drum

It’s full of hand brake dust.

This is the hand brake, the vehicle parking automatically relies on two out-of-chip supports to fix the vehicle.

Loosen the ball cage big nut

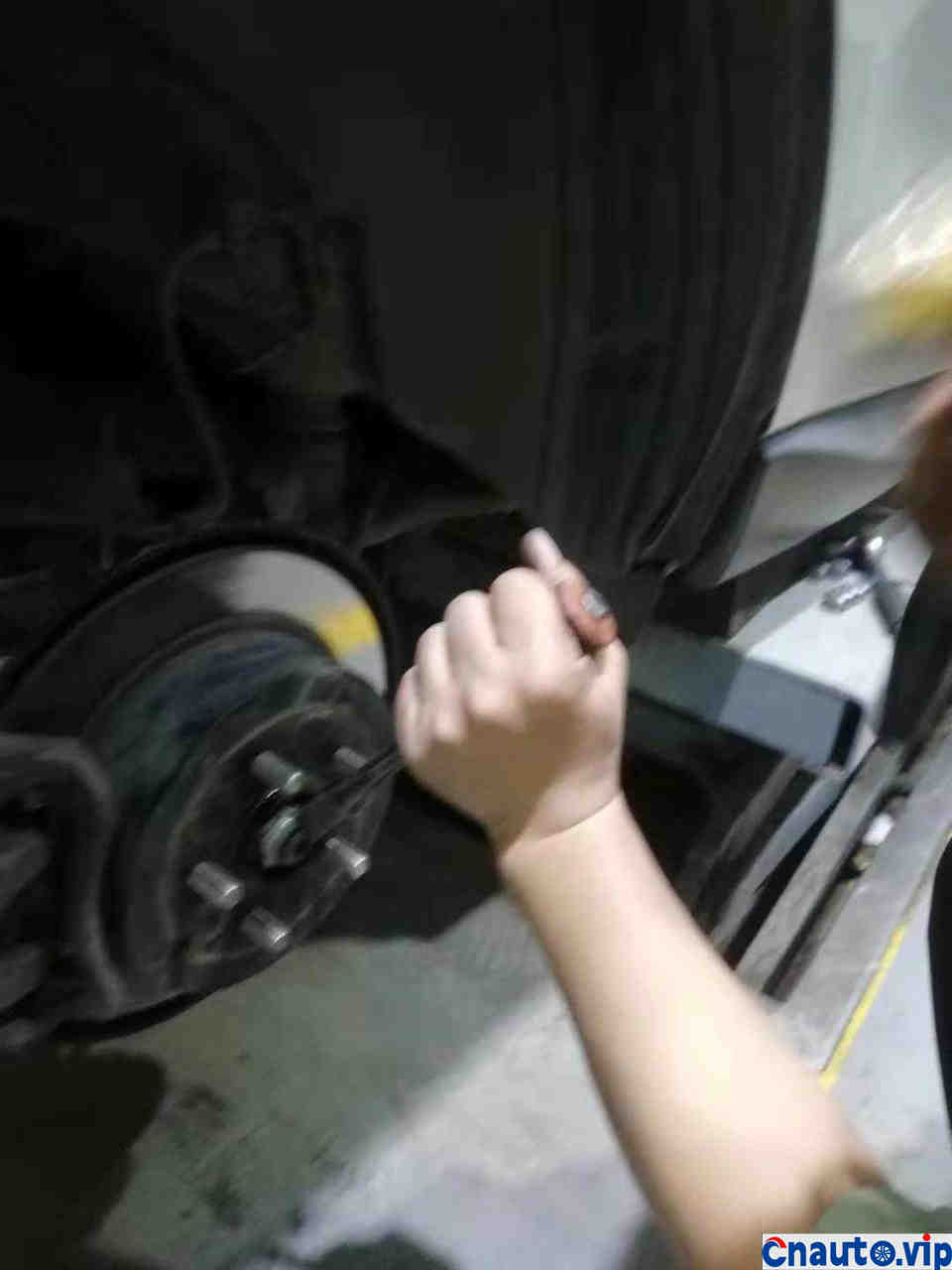

Remove the four screws on the back of the bearing

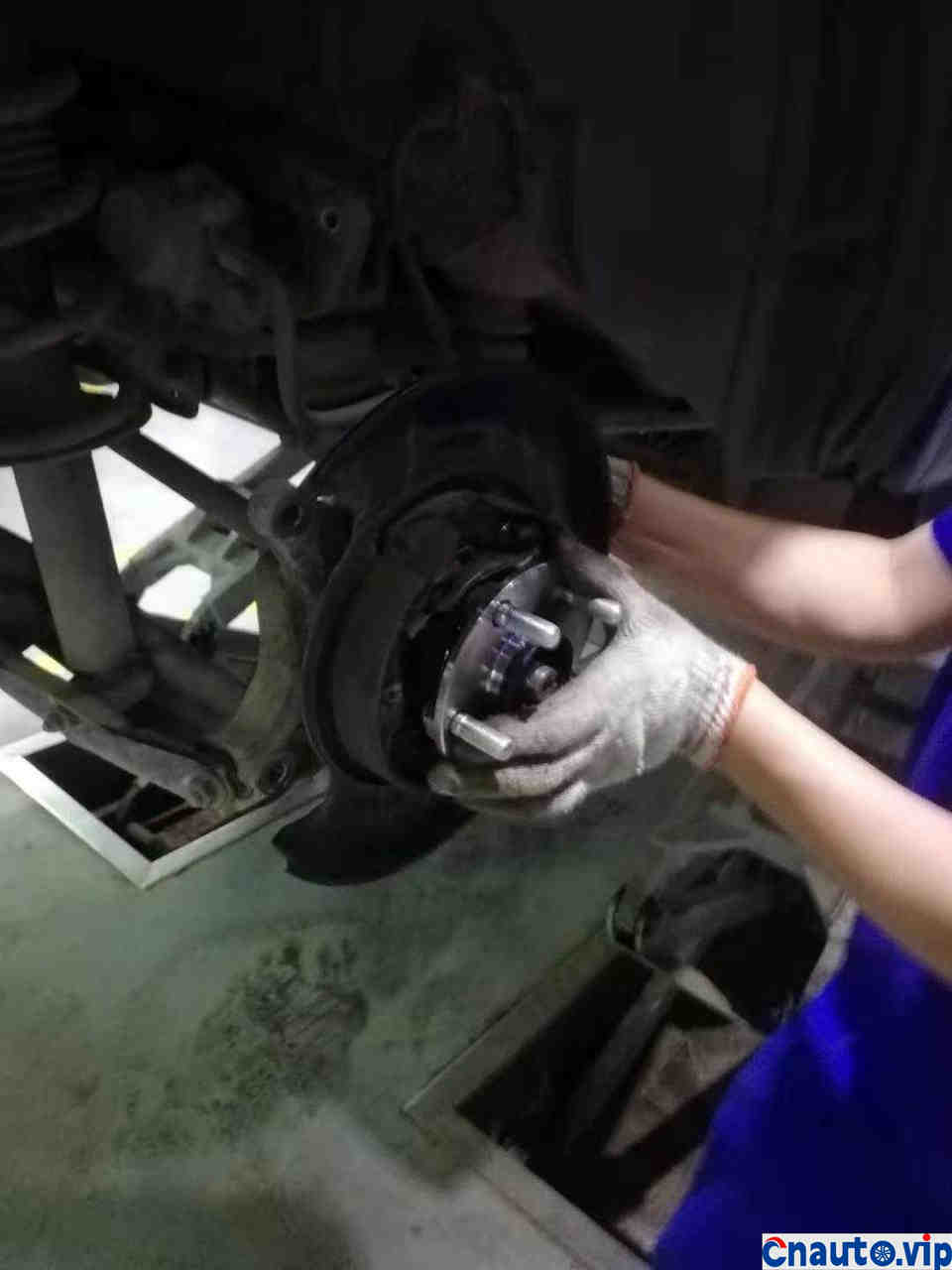

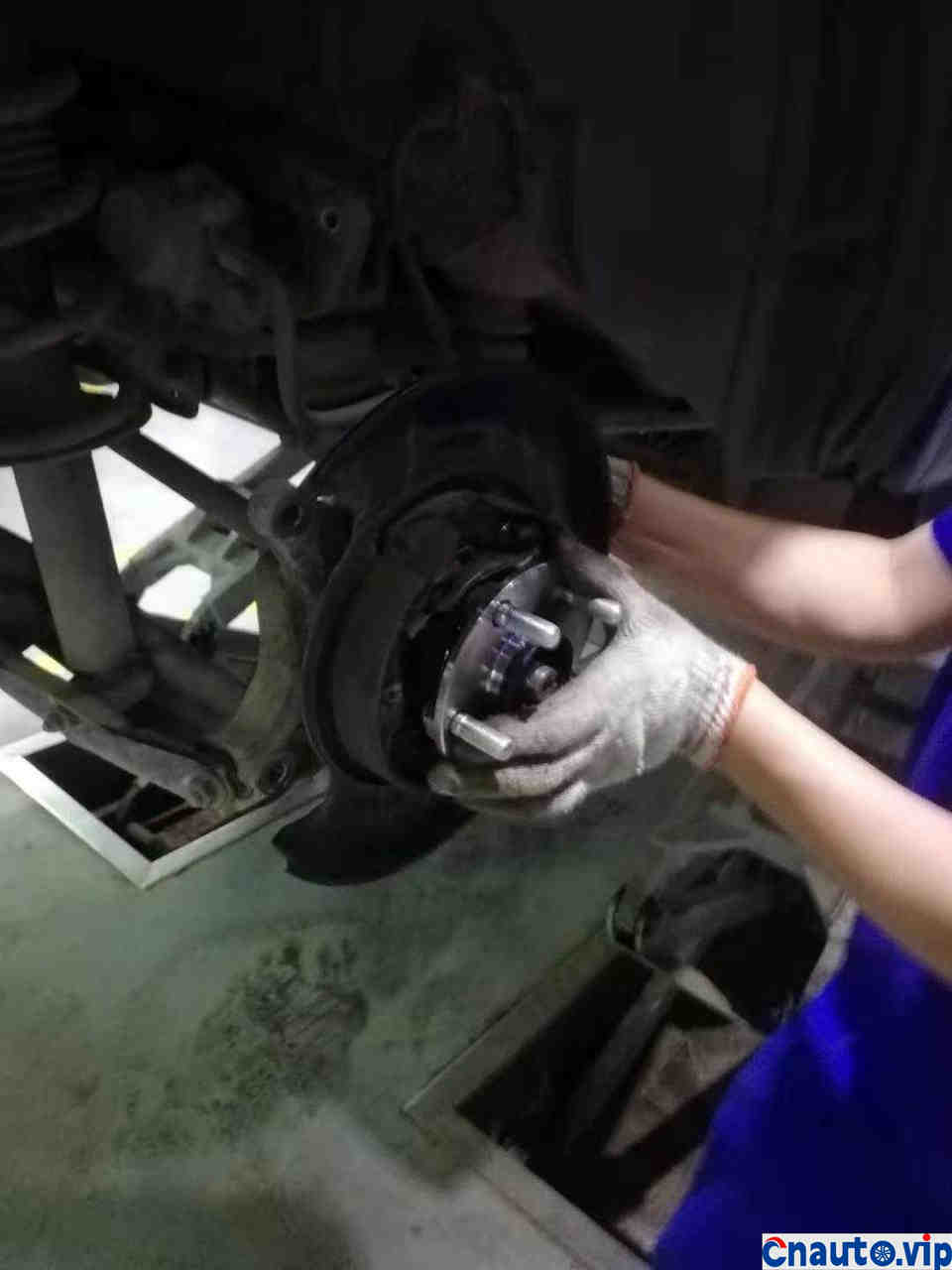

Remove the connecting plate and bearing

Then remove the bearing, and the all-in-one bearing, including the screws, is attached

Compare the new with the old, and remember to pay attention to the quality of the bearing.

Recently replaced bearings

Enter the installation process

In a good position

Start fixing the screw

The rear screws are fastened and the accessories are installed.

Install brake drum

Install the brake sub-pump bracket and pull as little as possible, because the brake tubing is soft and must be fixed when removed.

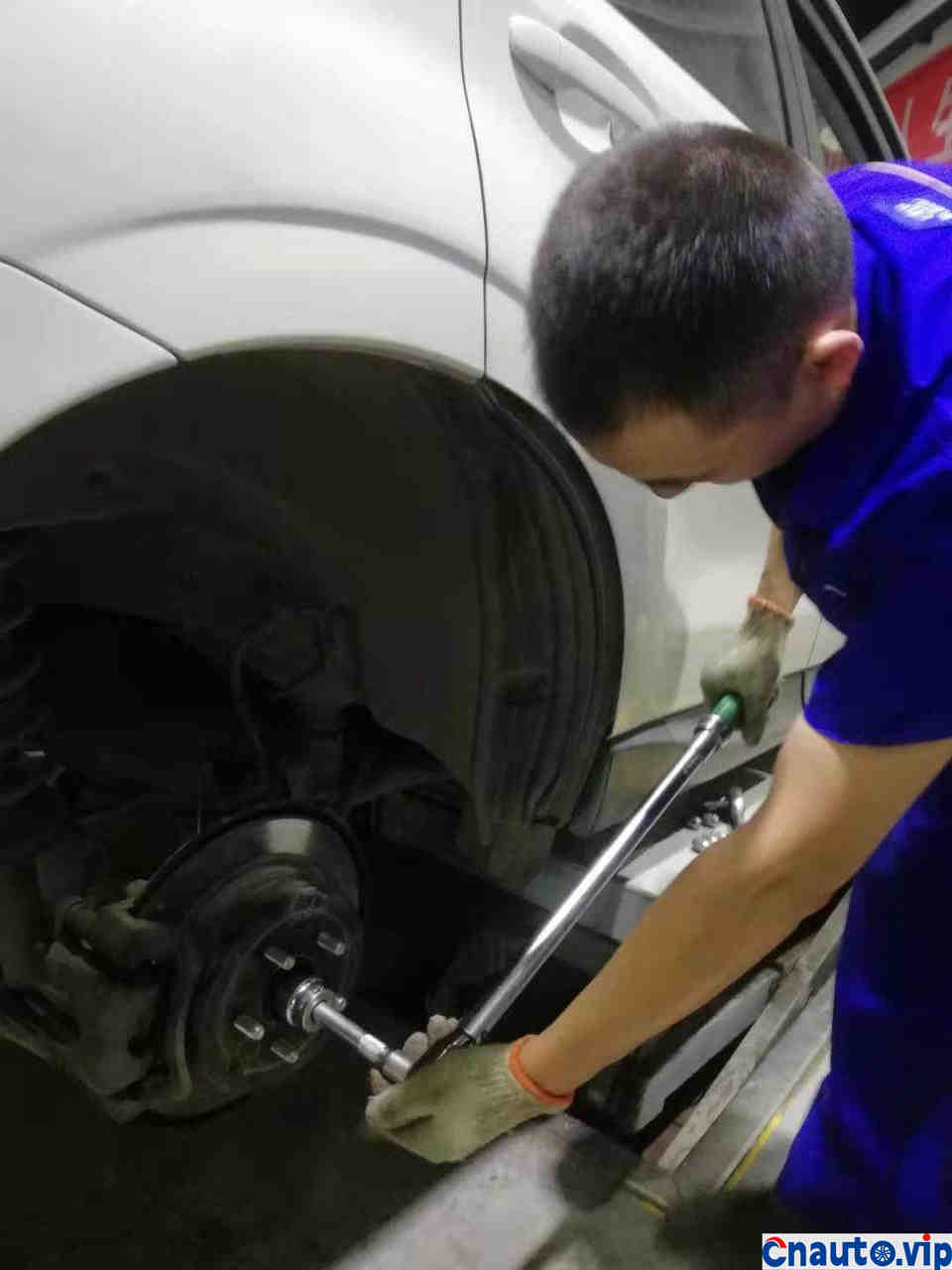

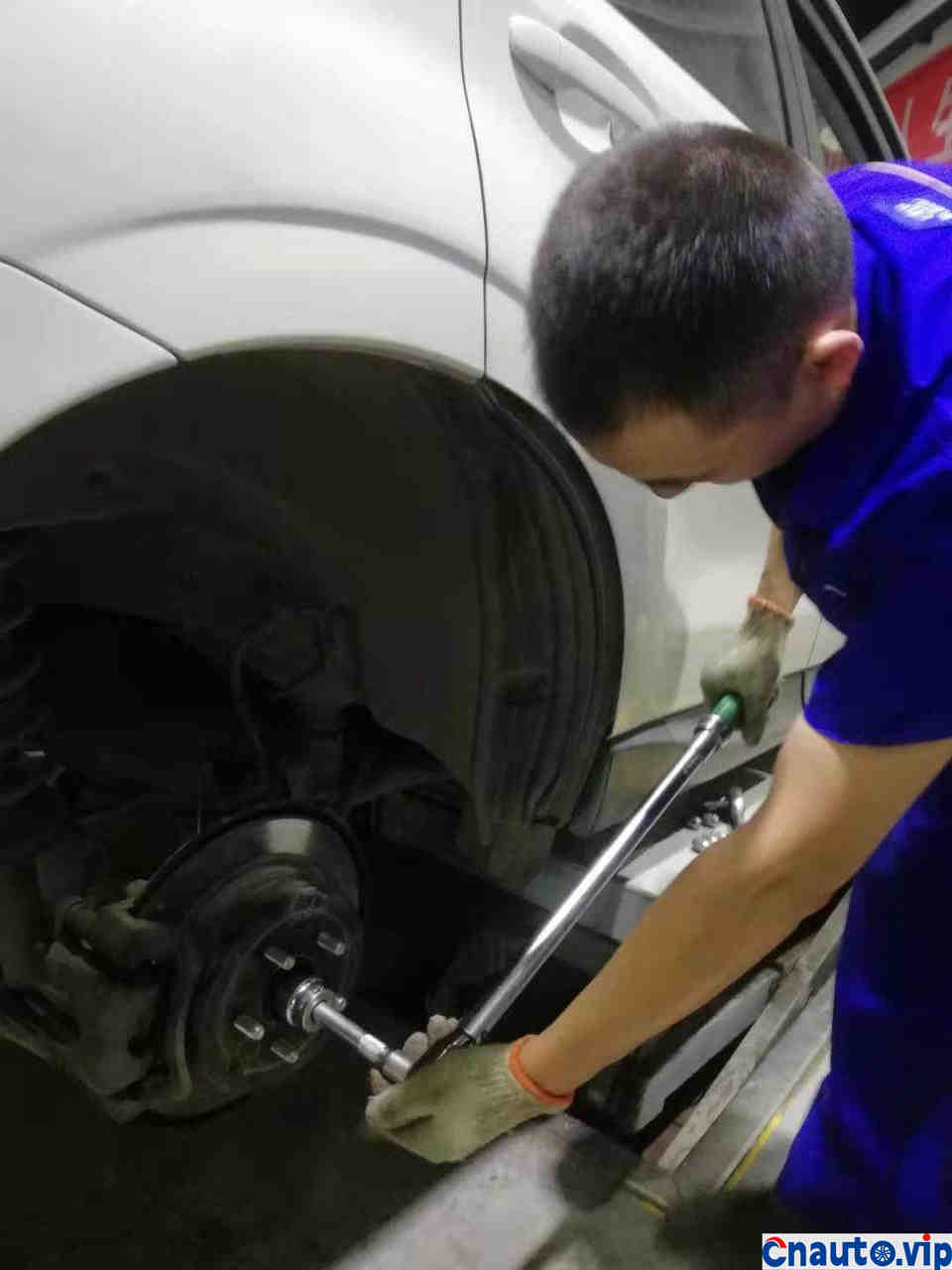

Tighten the middle big screw

Adjust the twist you need

Fasten to standard value

Then lock the nut and drive for a long time, causing the screw to loosen.

Locked nut

The installation of tire bearings has been replaced.

Front and rear bearings in the use process, such as wading in summer, such as water depth less than half of the wheel driving will directly affect the service life of the bearing. So in the rainy season every summer, do not let your car wade as much as possible, if you have to drive on a road that is as shallow as possible. After the bearing enters the water, the water, oil and friction will turn the grease into emulsion and lose the original lubrication effect. The lack of grease accelerates the wear of the needle roller and the inner and outer sleeve of the ball bearing, and the bearing noise comes out after a long time.

Replacement of bearings is recommended to choose a specialized shop, specializing in familiar with the vehicle structure to avoid a lot of detours, the quality of accessories has an absolute advantage.

After the introduction, I hope it will be helpful for the majority of cyclists to use the car. I want to know more about vehicle maintenance. Welcome to leave a message, and the next issue will be more exciting.

April 1, 2024

April 1, 2024