The name Volvo is Latin and means “rolling forward.” Volvo Cars ‘nameplates are made of steel-a circle (iron mark) with a diagonal arrow. The design idea for this sign originally originated from the Swedish steel industry, which is known for its durability.

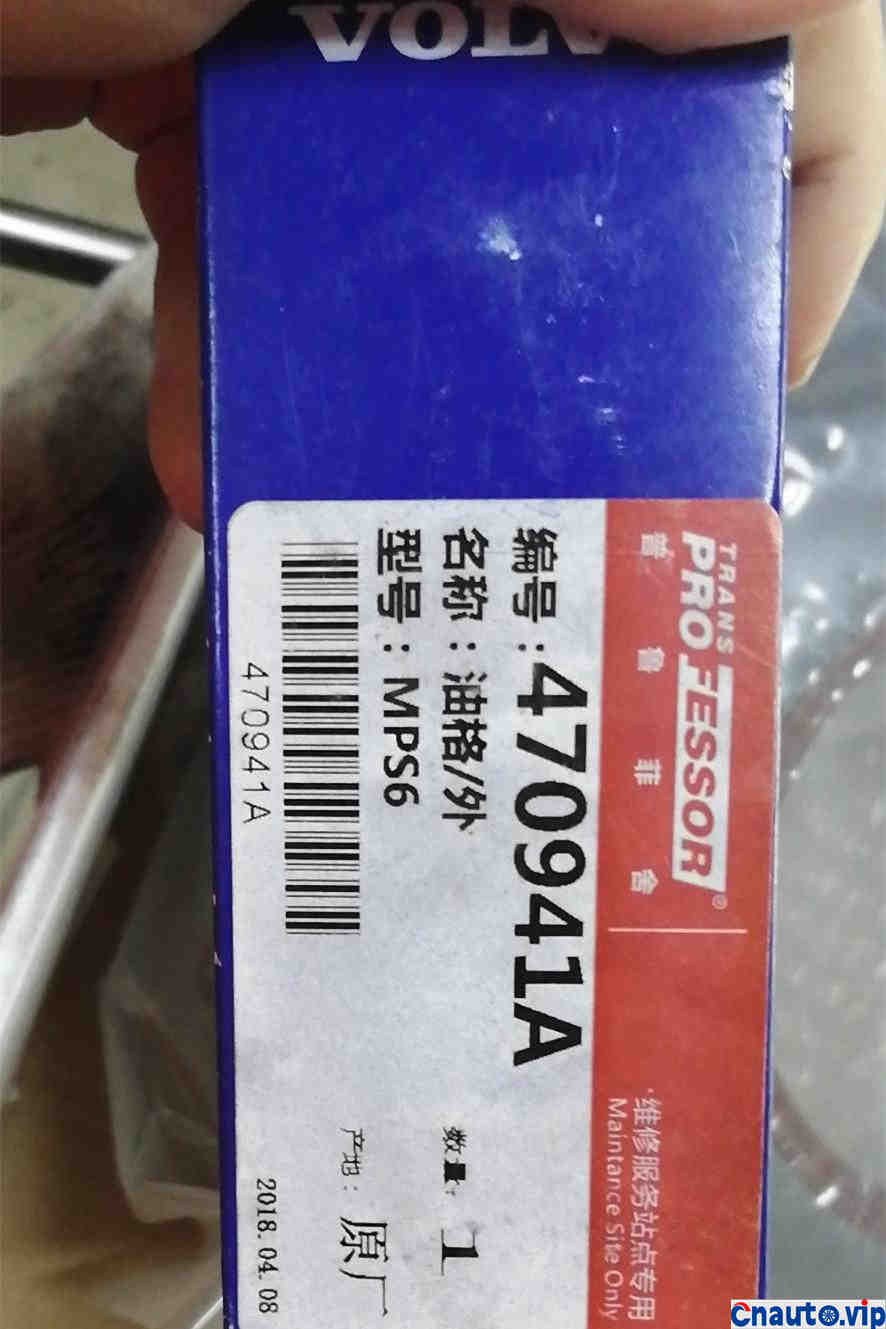

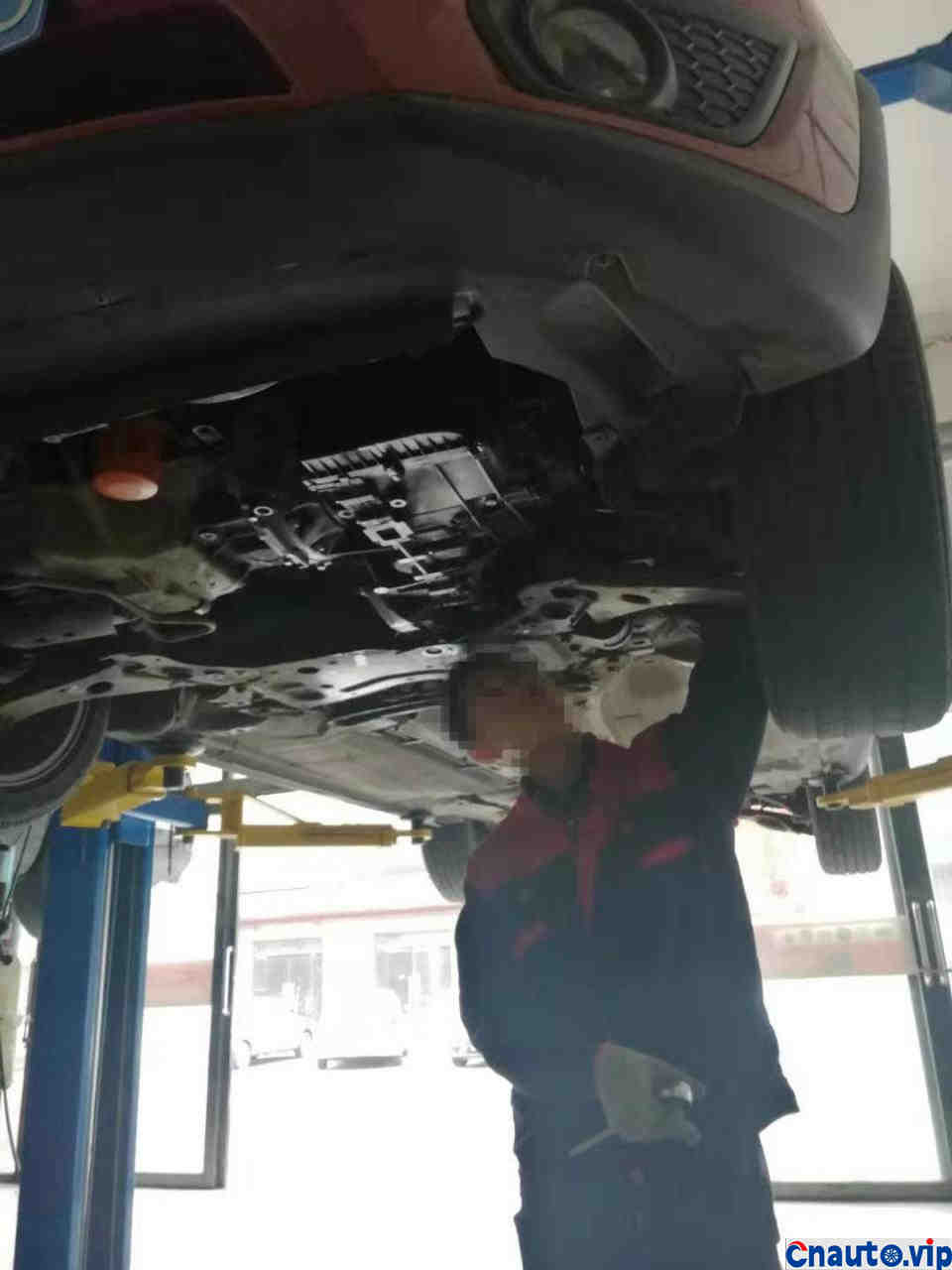

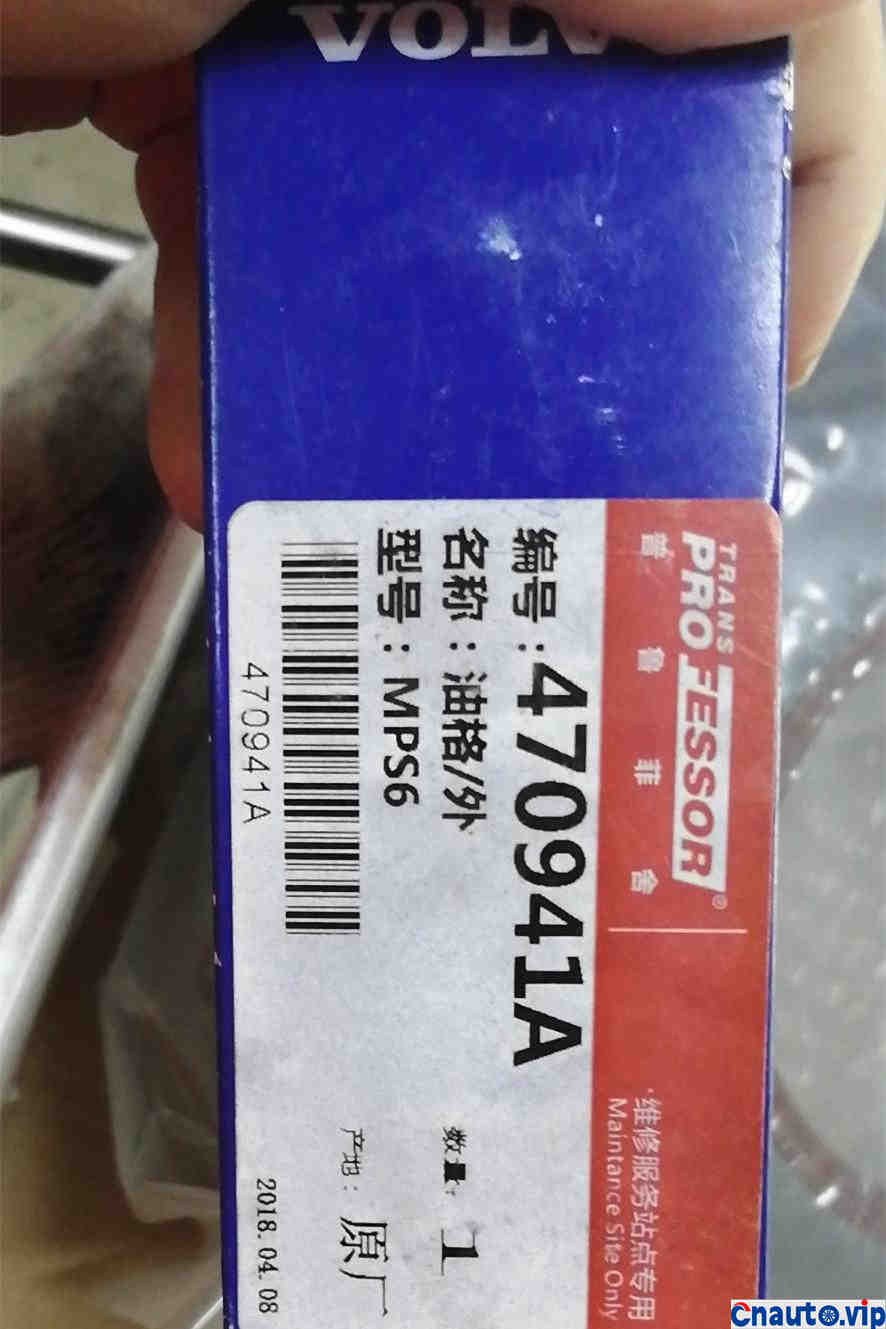

The car that came to the store for repair today is a Volvo C30 2011 2.0 R-Design. It is equipped with a gearbox: automatic 6-speed MPS6/6DCT450 dual clutch transmission. Next, let’s take a look at what’s wrong with this car’s gearbox.

The red body has a fashionable appearance and elegance. The front face is more masculine in the traditional family style, and the tail is round and sexy.

Kilometers traveled: 95043 kilometers. The instrument shows that the fault light has reported a code, and it seems that it really needs some good maintenance.

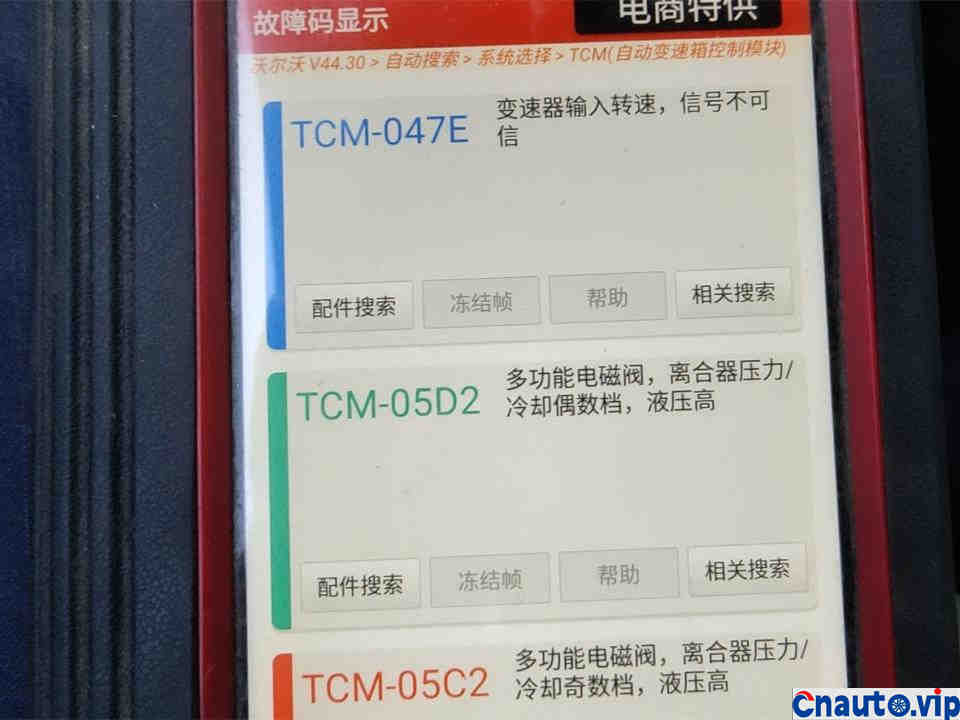

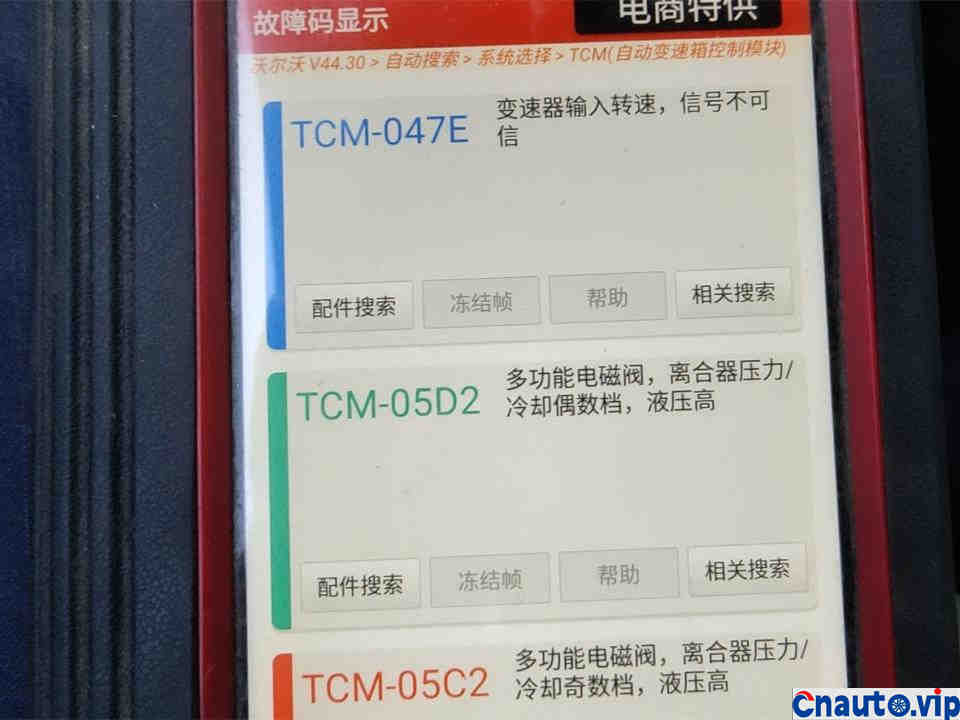

Connect to the computer to detect the internal fault code of the gearbox:

1. Transmission input speed, the signal is not credible;

2. Multi-function solenoid valve, clutch pressure/cooling even gear, hydraulic pick.

3. Multi-function solenoid valve, odd clutch pressure/cooling gear, high hydraulic pressure.

Both the interior of the gearbox and the electromechanical control unit need to be repaired out of the box.

Prepare for open-box inspection, repair and open-box;(neat engine compartment, obvious Volvo logo).

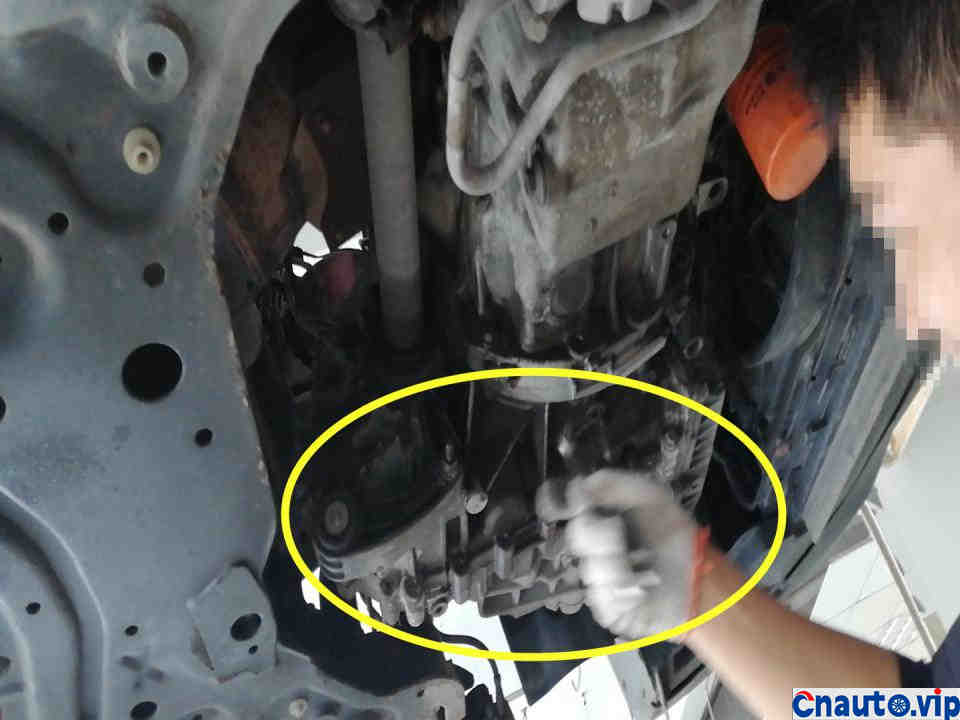

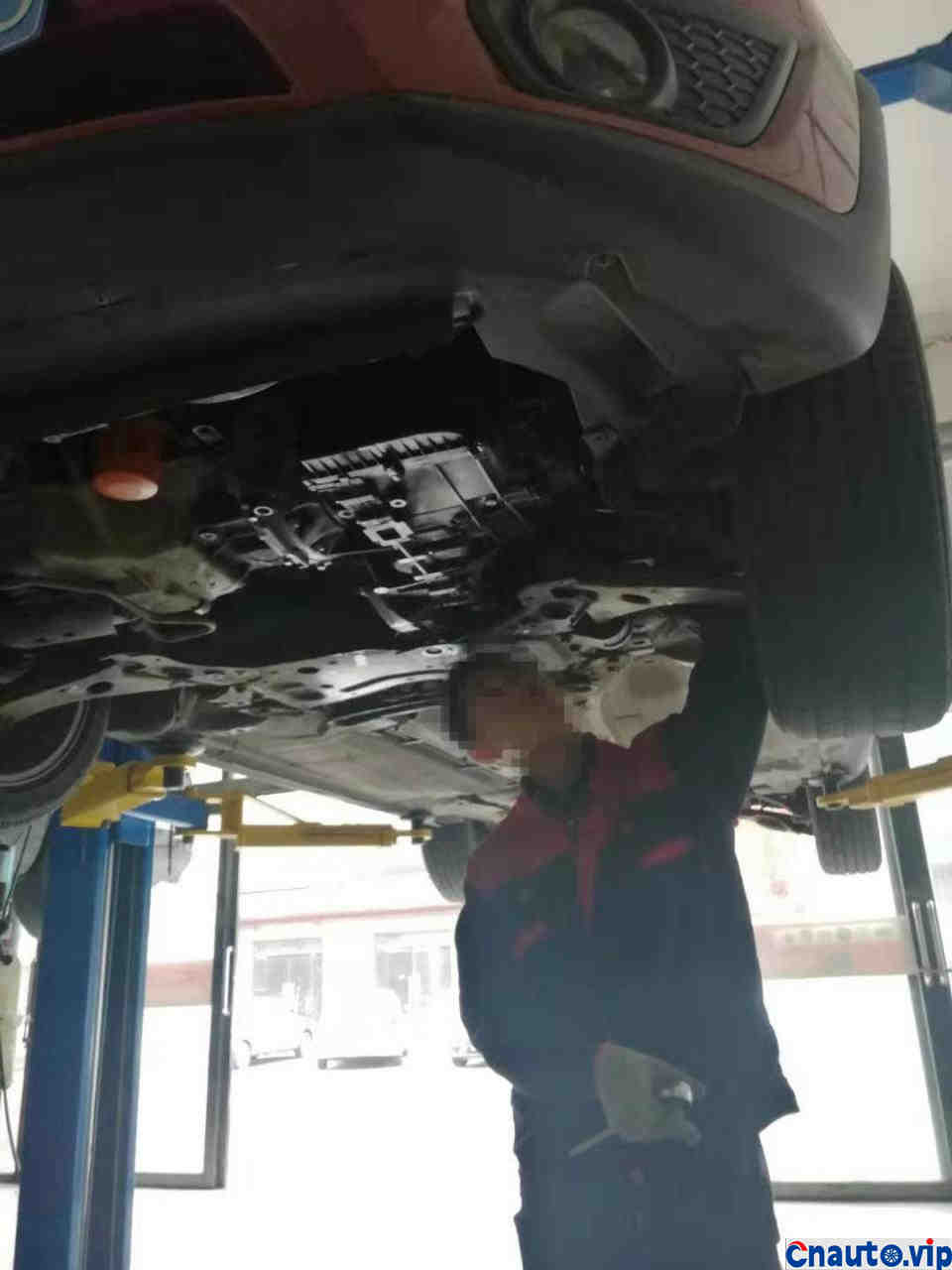

Prepare to remove the gearbox,

The maintenance master is carefully dismantling it;

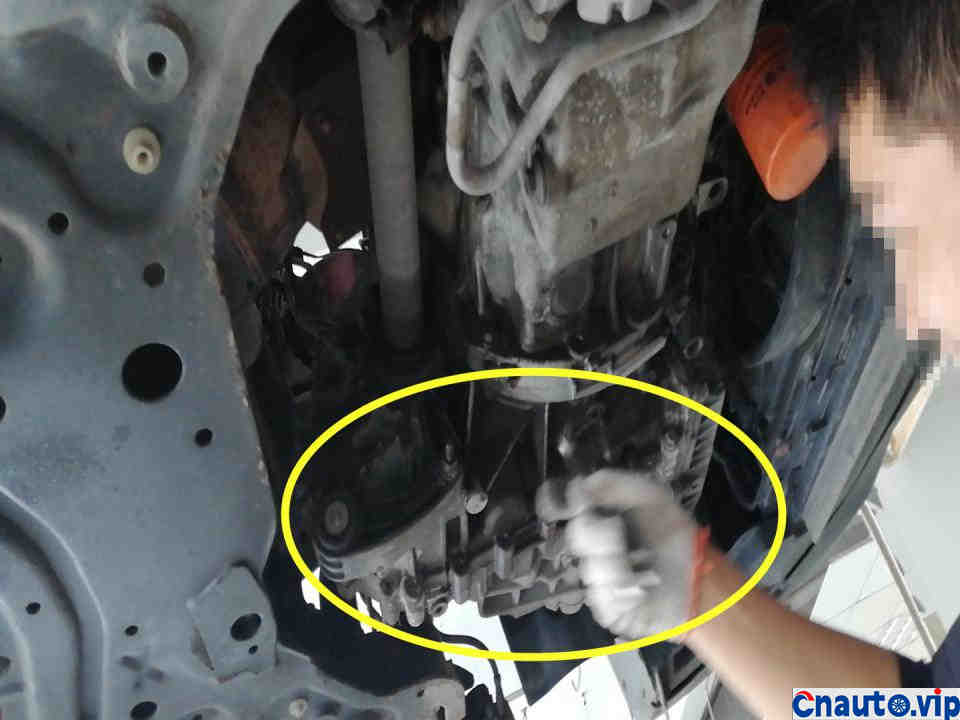

The upper shelves are being disassembled;

Drain the oil inside the gearbox;

Remove the connection between the gearbox and the engine;

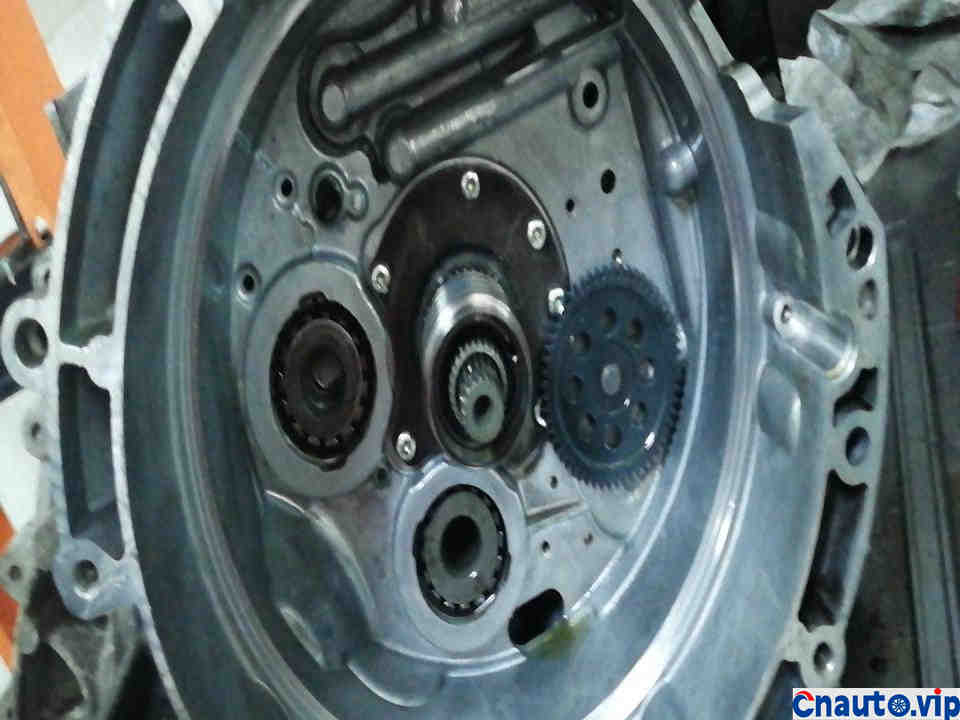

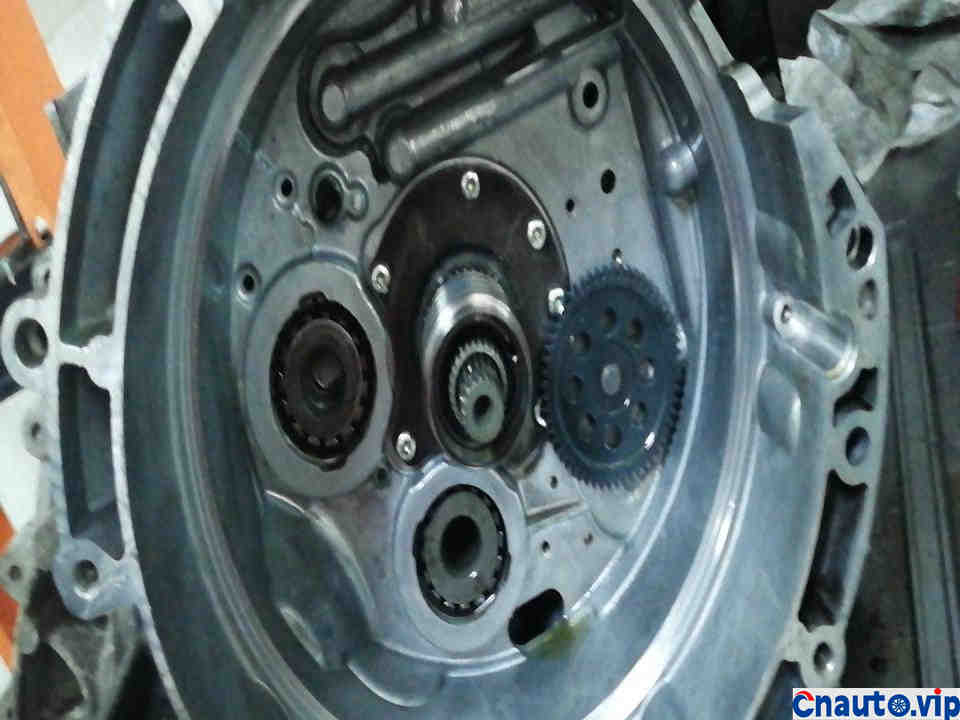

Internal diagram of the gearbox after removing the shell;(gear distribution is clear and tidy)

Clean transmission housing and parts;

Replaced electromechanical control unit valve body;

Gearbox oil pan;(iron filings from worn internal gears)

The steel plates and friction plates in the gearbox are being tested and installed (replacing worn parts), and the gearbox is being assembled;

Schematic diagram of the internal casing of the transmission

Replacement of new oil seals;

Replace internal gasket pack and sealing pack

Replacement of original oil compartments;

Install it on the shelves to ensure that the bottom bolts and brackets are firmly installed, check for oil leaks, and then conduct test for gearbox use.

After the master’s test run was completed, the gear shifting was normal without setbacks, and the vehicle was delivered after maintenance.

This gearbox repair was mainly due to the failure of the gearbox electromechanical control unit and the wear of internal friction plates and gear parts, which caused the gearbox failure repair.

April 1, 2024

April 1, 2024