[Daily car maintenance] Audi Q5 suddenly does not have reverse gear (maintenance)

Today’s maintenance is an Audi Q5 according to the car friend said that when reversing, there was no reverse gear, and the shift was not smooth before, and the instrument indicated that there was no reverse gear, so I went to the store for inspection. This vehicle is equipped with an EA888 second-generation engine, which matches the seven-gear double clutch code 0B5 vertical power package. The 0B5 gearbox is equipped with a lot of equipment in the Audi car. Porsche Marka is also equipped with this gearbox, and there are many reasons why there is no reverse gear. The following reasons can cause this fault, from simple to complex, 1 row of wire failure (usually report the fault in the solenoid valve) 2 valve body, 3 clutch, 4 gear switch, 5 synchronizer, fork, 6 computer, from simple to complex one by one. After 2pr 3 hours of troubleshooting, the mechanical fault is locked in the gearbox, and the specific problems need to be disassembled.![]() After several days of maintenance, the vehicle will be returned to the car friends on time. Thank you for their trust.

After several days of maintenance, the vehicle will be returned to the car friends on time. Thank you for their trust.![]()

Common sense of car maintenance and repair, the cause of car failure can be found here. If you want to know more about your car, here is a good way to supplement your car knowledge. No matter for me or for you, it is an opportunity to get to know each other and the beginning of making new friends. It may not be reproduced without the permission of the original work![]()

Common sense of car maintenance and repair, the cause of car failure can be found here. If you want to know more about your car, here is a good way to supplement your car knowledge. No matter for me or for you, it is an opportunity to get to know each other and the beginning of making new friends. It may not be reproduced without the permission of the original work

When the car friend came, the instrument always indicated the fault, but arrived safely, and then we checked the fault.

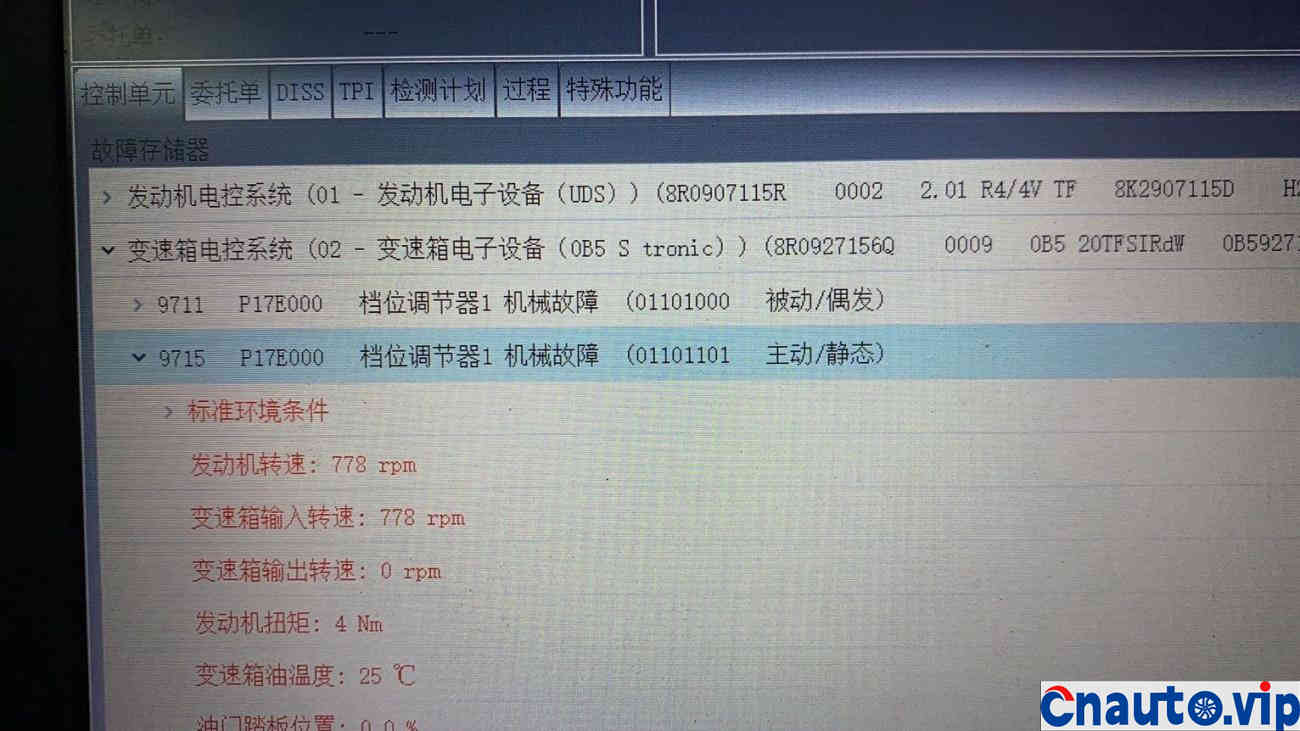

The fault code read by the computer, and then we began to check for possible faults.

At first, the fault code misled us for a while, thinking that it was a gear failure, but we looked up the data and thought that the logic was wrong.

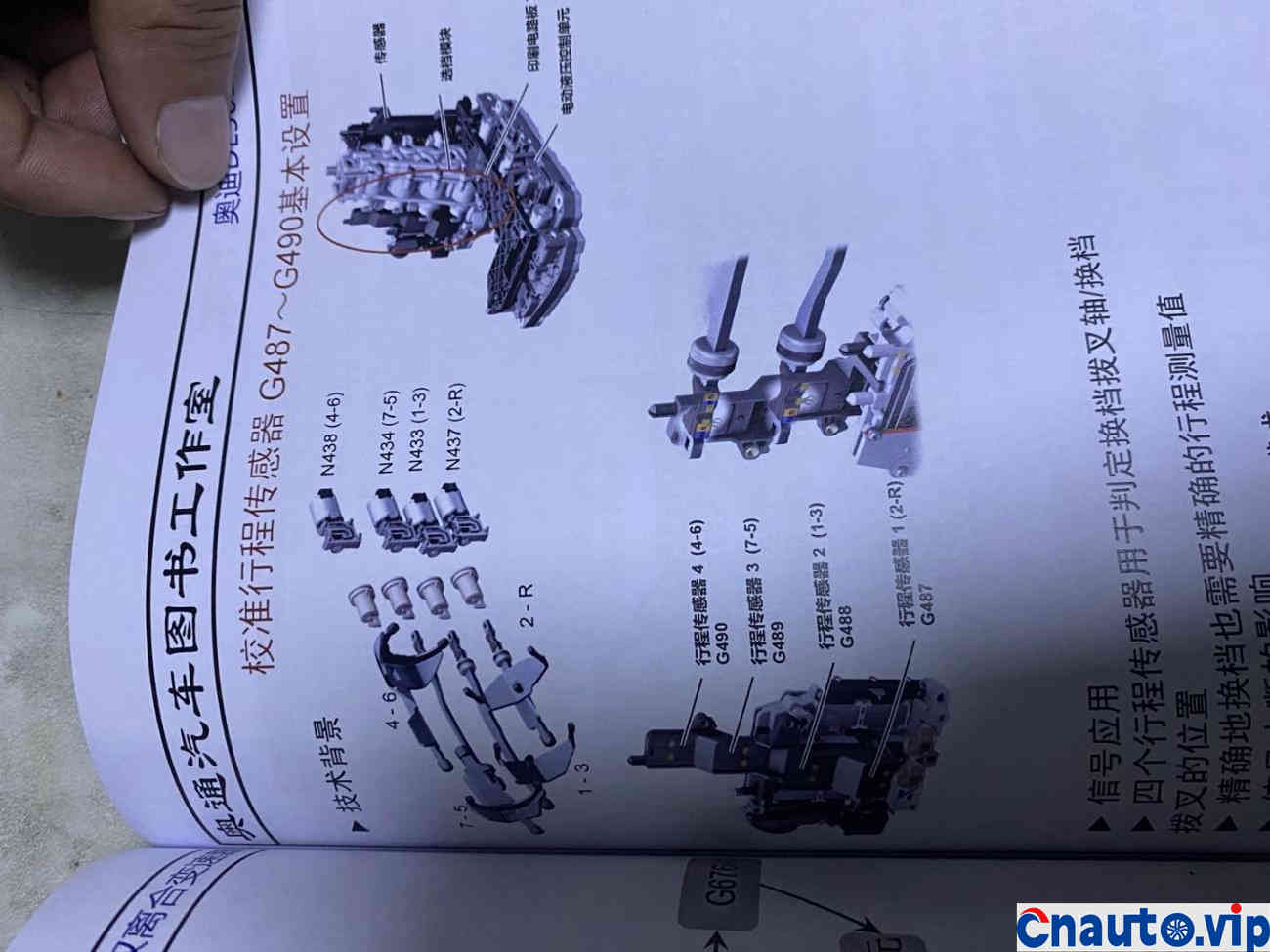

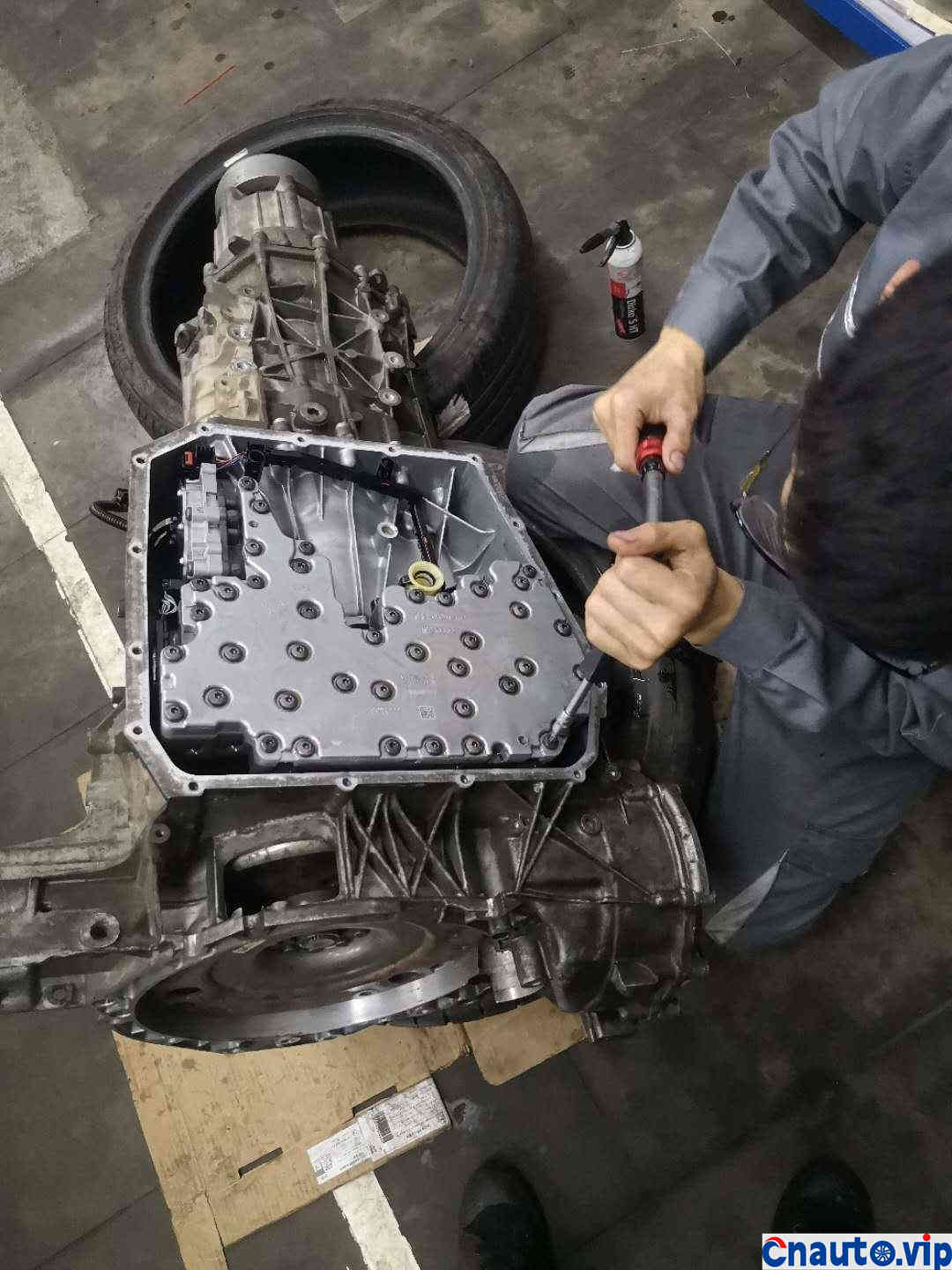

The picture shows the core part of the gearbox of the electromechanical control unit, which is equivalent to its brain.

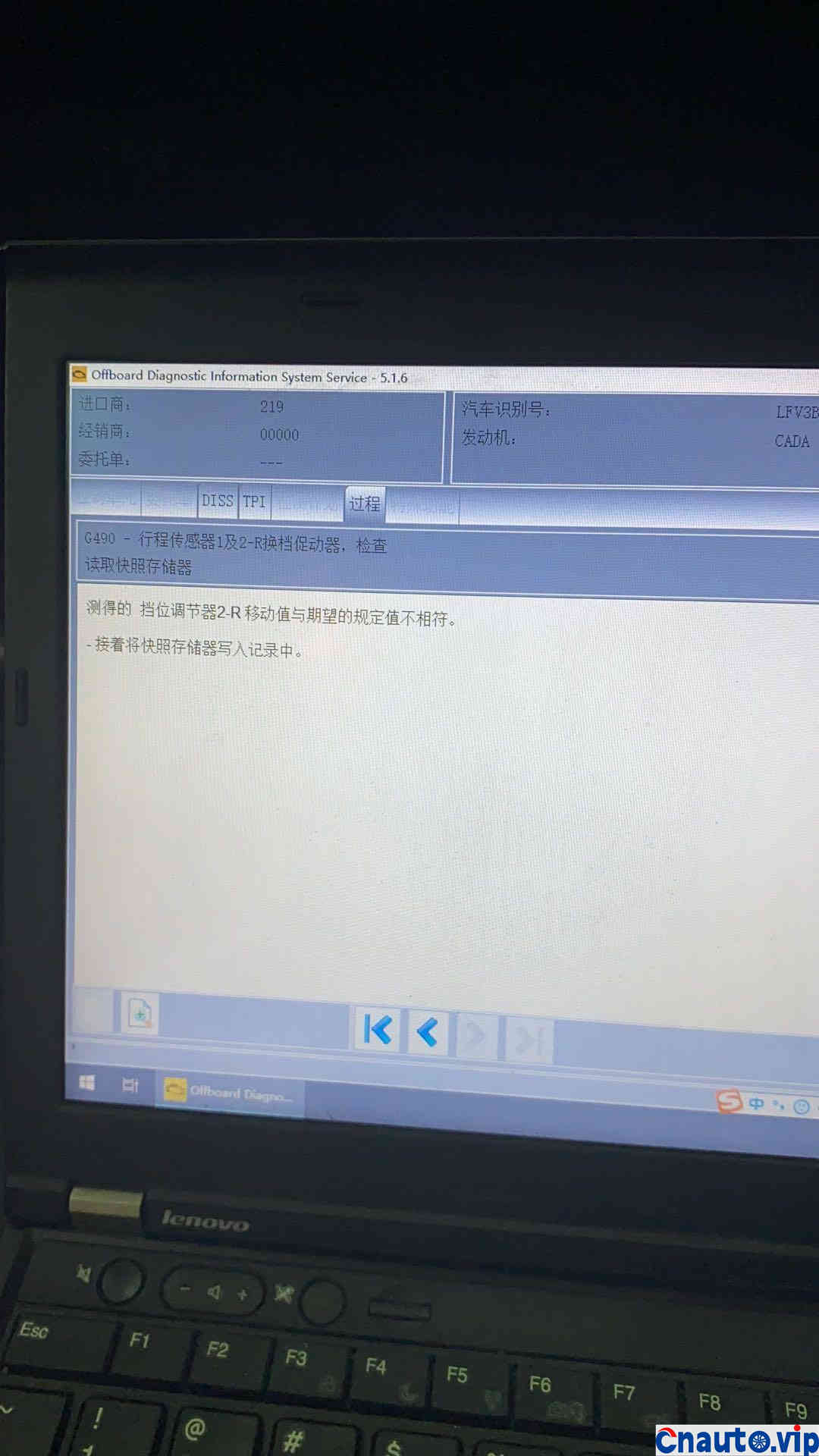

In the end, we determined that the fault was in 2 R reverse gears. who would be a mechanical problem because these two gears share the same fork? However, it is very troublesome to check the interior and we have to dismantle the gearbox. In line with the principle of caution, we first rule out the three possibilities of valve body, computer and wiring.

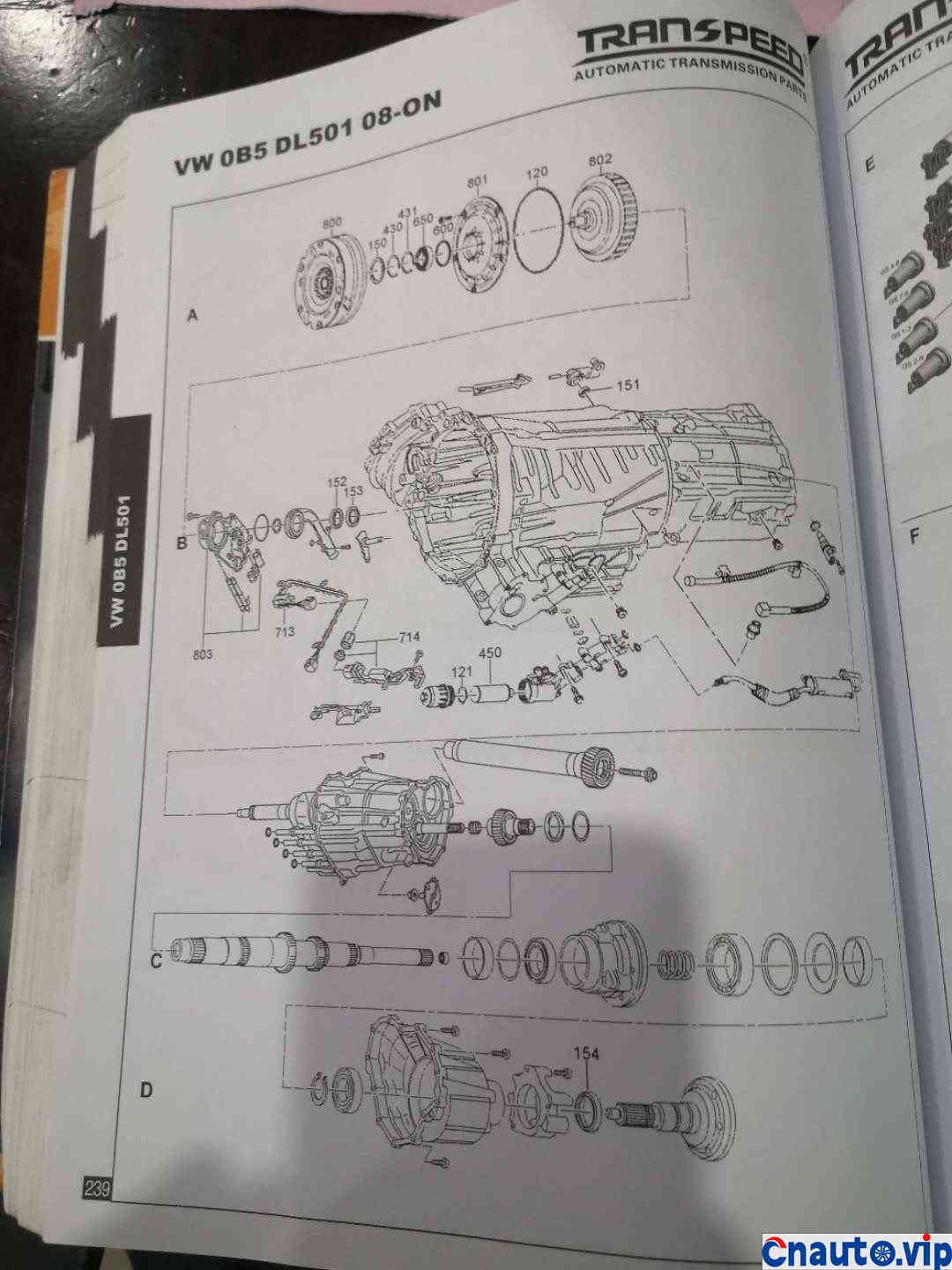

Access to data

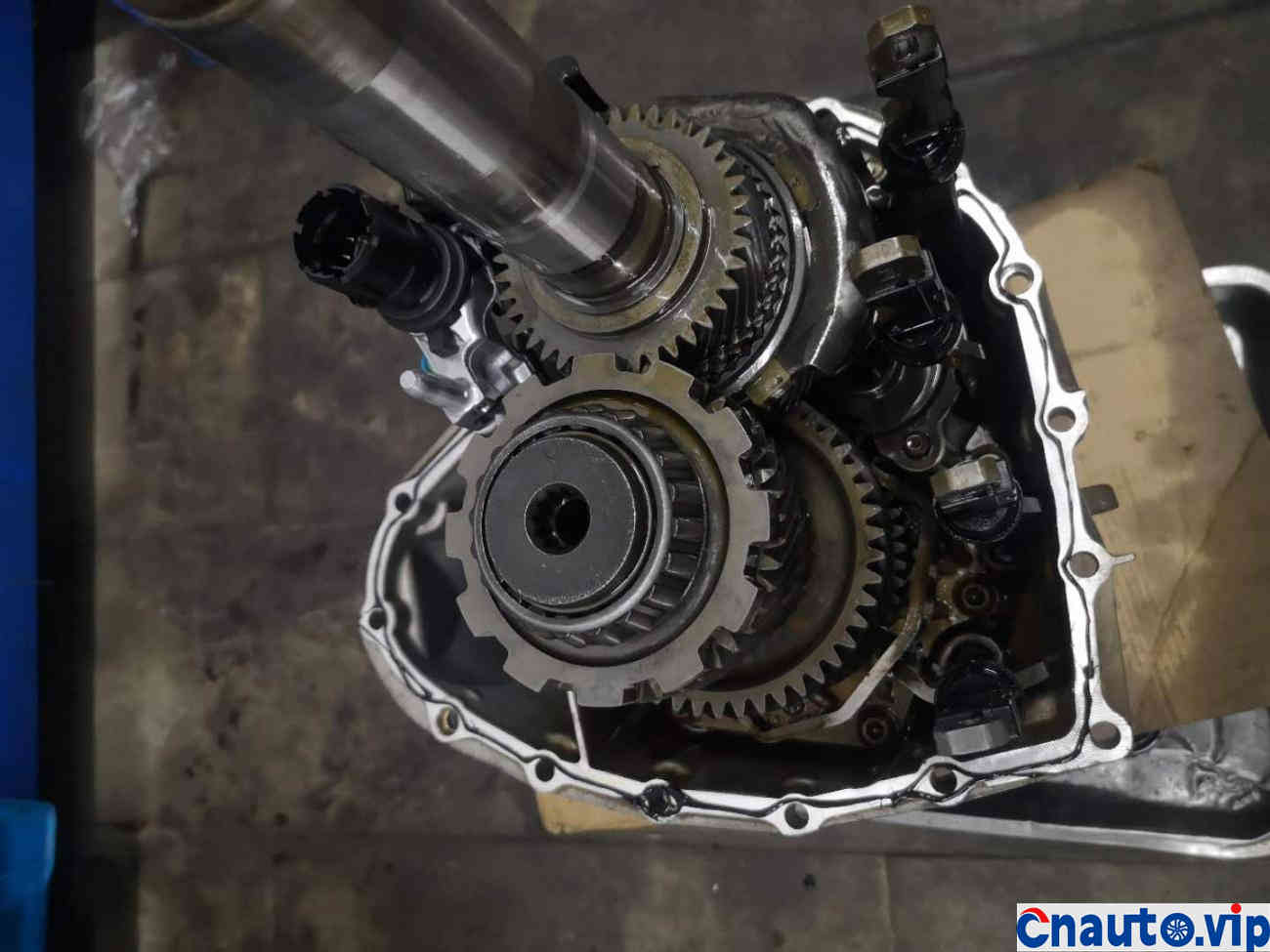

Internal structure

When we replaced the valve body unit, we found that the gearbox had been repaired. It is said that the internal problem should not be big.

We replaced a set of spare experimental electromechanical units borrowed from our friends to see if the fault had changed.

The computer is replaced together, anyway, it has to be removed, and the replacement of the computer needs to remove the guard against theft.

We need to replace the transmission oil, 7-gear wet double clutch transmission special oil. There are two kinds of oil in the gearbox. Different

It takes about 2.3 hours to install and remove the valve body.

The inner filter element we replaced is Mahler’s, the oil base pad is authentic Erlingmi, and the quality is guaranteed.

Hopefully put him on, the result is disappointed, the fault is still the same, needless to say now the remaining internal failure, the specific reason is only to disassemble the gearbox to check the interior. The next day I started to unpack the gearbox.

The next morning, the engine was fixed and the gearbox was disassembled.

It took a long time to remove the gearbox, and three screws broke and needed to be replaced.

Re-remove the valve body and disassemble the gearbox

The picture shows the double clutch of the gearbox, in which there are two sets of clutch plates, air tube 1.3.5.7. And 2.4.6.R several gears, when he has a problem, there will be no gear, when disassembling, it is found that there is a lot of sealant disassembled, it seems that for some time, the interior should not be decomposed, I do not know what the reason for maintenance, today we are going to solve the problem.

The structure of this transmission is not very complicated.

What you see now is the oil pump and the input shaft.

Classify the disassembled screws and mark them.

The outer ring screws of the gearbox are all replaced with new ones, and the aluminum alloy screws are replaced together under certain conditions. The screws are about 25 yuan each.

The front drive shaft, I didn’t expect it to be hidden inside.

This is the gearbox, we check next to the place where problems may occur, visual observation did not find iron filings and abnormal wear, the gearbox can basically be ruled out, but this step suggests that the shift switch will be replaced with a new one. After all, it is easy to have problems in the later stage of the shift switch, and the key is that the replacement and removal of the gearbox is expensive, so we replaced a brand-new shift switch.

Install a brand new gear switch.

The possibility of the gearbox is discharged, and then put it back.

Internal structure.

The shift switch of the brand-new original factory is not quite the same as imagined.

The double-sided oil seal isolates the gear oil and the valve body oil, and we replace the brand new imported Codick oil seal for insurance.

Looking back, we disassembled the clutch, and the first fault appeared in front of us.

The clutch burned out.

The friction disc has gone on strike completely because of the high temperature.

Not the worst I’ve ever seen.

The burning is very serious, so why did the clutch burn off? there must be some other reason that will cause the clutch to burn off. We also found the reason why the clutch burned out.

When we fix the clutch, it still takes some skill to fix this thing. Fortunately, some friends used their special tools with the help of their friends.

Two oil seals ordered.

Solenoid valve that needs to be replaced.

Due to the late time, it was installed back the next day.

The conditions are limited, so we have to wrap the gearbox with thin film to prevent foreign bodies.

Continue to assemble the gearbox the next night, and there are other things to do during the day.

Install the block switch wire harness.

Installation and maintenance instructions to tighten the clutch screws.

The plug inside the gearbox is not easy to install.

The tail shell also needs sealant.

The torque of valve body screw is about 10 Nm.

Reinstall the strainer.

No sealant is needed to replace the new gasket, and the sealant can not be used everywhere.

The gearbox was really heavy when it was dismantled.

The next day to install the test drive, re-online anti-theft test trouble thoroughly eliminated, road test 70km shift normal OK.

After several nights of overtime maintenance, the vehicle was finally delivered to the riders on time. Thank you for your trust. When we encounter problems, we will study them and find ways to solve them.

Hot Information

Tesla Autopilot and similar automated driving systems get ‘poor’ rating from prominent safety group

April 1, 2024

April 1, 2024 Localization of EV parts without production scalability may not help cut EV price, says President, Amara Raja

March 27, 2024

March 27, 2024

JCTSL may turn bus stands into charging points for e-buses

March 27, 2024

March 27, 2024 You May Like