11 Touran replacement rear balance bar rubber sleeve, connecting rod

In the past few years, when braking at low speeds, there would be a loud crunch at the rear of the car body. I bought a rubber sleeve for the rear balance bar (stabilizer bar) and a connecting rod.

Once, the screws of the rubber sleeve fixing the cover were removed, but the rubber sleeve could not be removed and it was never replaced.

This National Day holiday, I looked for an opportunity to change together.

Once, the screws of the rubber sleeve fixing the cover were removed, but the rubber sleeve could not be removed and it was never replaced.

This National Day holiday, I looked for an opportunity to change together.

The mileage is 255,000.

It is inconvenient to use a single jack to remove the balance bar. Because after the car tilts, the balance bar is twisted and it is difficult to remove. Therefore, a plastic ramp is used and the rear wheel is parked on the ramp for easy removal.

It is inconvenient to use a single jack to remove the balance bar. Because after the car tilts, the balance bar is twisted and it is difficult to remove. Therefore, a plastic ramp is used and the rear wheel is parked on the ramp for easy removal.

important reminder

Important reminder: The ramp did not fit, resulting in later rework.

important reminder

Important reminder: The ramp did not fit, resulting in later rework.

important reminder

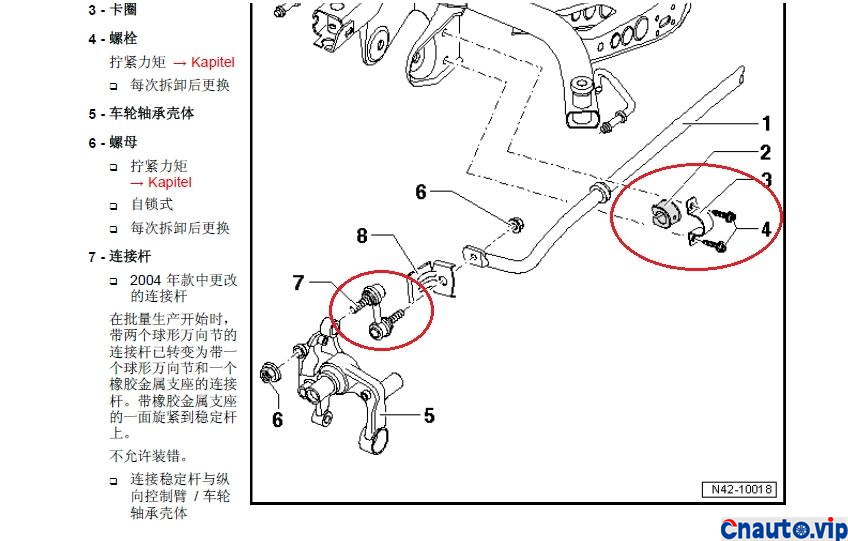

One end of the connecting rod is fixed on the longitudinal control arm, and the other end is fixed on the balance bar. One end of the connecting rod has a ball head and the other end is rubber sleeve. Both of them require an M6 outer 12 angle tool to fix the inner core before unscrewing the nut.

Due to the existence of the tire, there is very little space for disassembling the nuts on it, which requires a small tool to fix the inner core and an open-ended wrench. It is a bit difficult to remove, and it takes some time to remove one side.

On the other side, a horizontal jack was used to lift the car up and remove the wheels, then remove the nuts on the upper part of the connecting rod, and then put the wheels back on the ramp.

I still thought about it later. You can remove the wheels before driving up the ramp, unscrew the nuts on the upper parts of the connecting rods on both sides, then install the wheels back, drive up the ramp and continue dismantling. This may be easier.

On the other side, a horizontal jack was used to lift the car up and remove the wheels, then remove the nuts on the upper part of the connecting rod, and then put the wheels back on the ramp.

I still thought about it later. You can remove the wheels before driving up the ramp, unscrew the nuts on the upper parts of the connecting rods on both sides, then install the wheels back, drive up the ramp and continue dismantling. This may be easier.

Comparison between old and new

Hot Information

Tesla Autopilot and similar automated driving systems get ‘poor’ rating from prominent safety group

April 1, 2024

April 1, 2024 Localization of EV parts without production scalability may not help cut EV price, says President, Amara Raja

March 27, 2024

March 27, 2024

JCTSL may turn bus stands into charging points for e-buses

March 27, 2024

March 27, 2024 You May Like