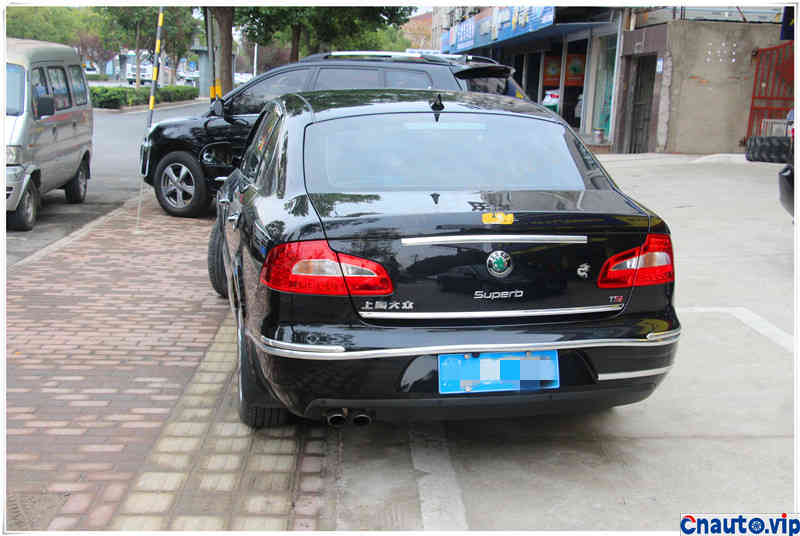

Old shoes are okay, but I’d better replace them with new ones for safety reasons!

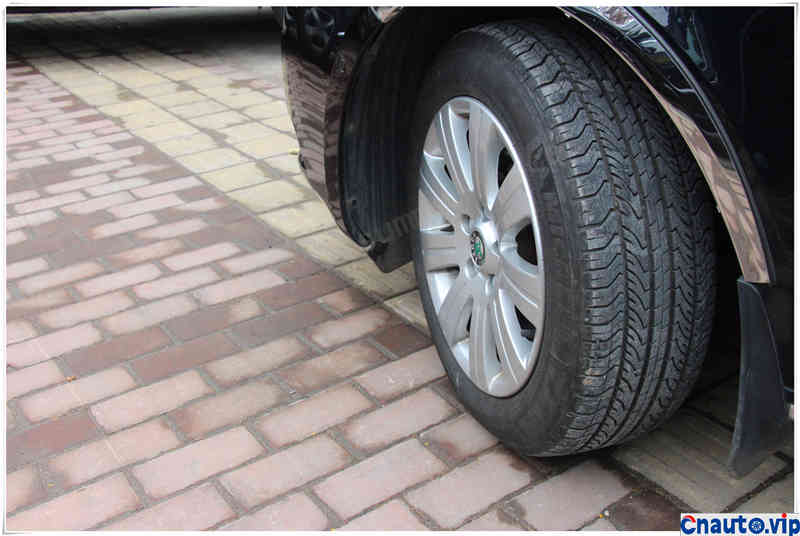

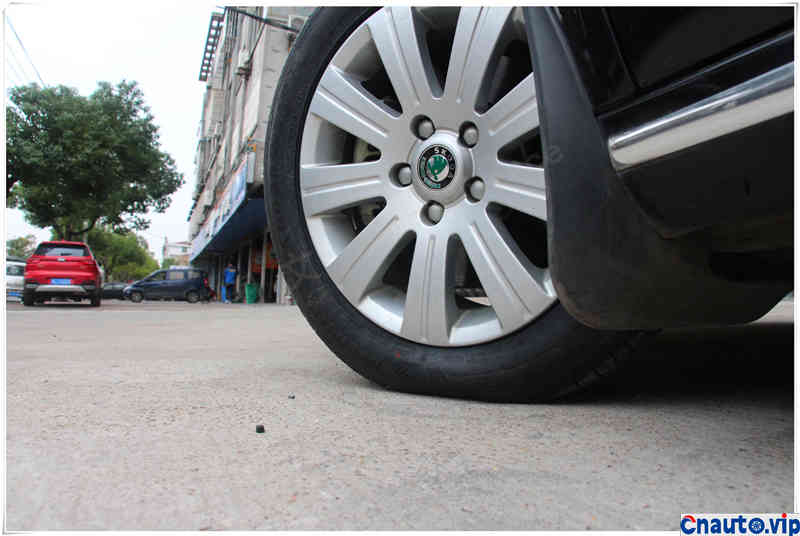

My Haorui is currently in its eighth year, and the car is still the original Michelin tires, model number 205/55R16, 94V. These tires cost more than 1000 yuan each back then. The higher the speed of the car, the higher the requirement for the V-level. Currently, the Michelin model tires are only 91V, but it is enough for ordinary cars. This time I didn’t choose Michelin, but chose Goodyear, which is also a big brand. Let’s experience other brands. For this grade of tires, the selling price for a certain east is about 500 yuan each.

My Haorui is currently in its eighth year, and the car is still the original Michelin tires, model number 205/55R16, 94V. These tires cost more than 1000 yuan each back then. The higher the speed of the car, the higher the requirement for the V-level. Currently, the Michelin model tires are only 91V, but it is enough for ordinary cars. This time I didn’t choose Michelin, but chose Goodyear, which is also a big brand. Let’s experience other brands. For this grade of tires, the selling price for a certain east is about 500 yuan each.Recently, the weather here was suddenly cloudy and rainy. I finally found a Tuesday when it didn’t rain and went to the store for installation and construction.

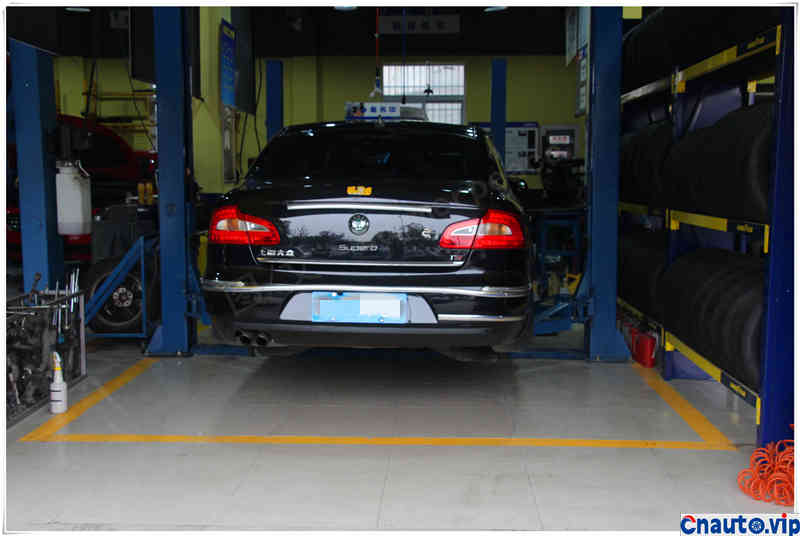

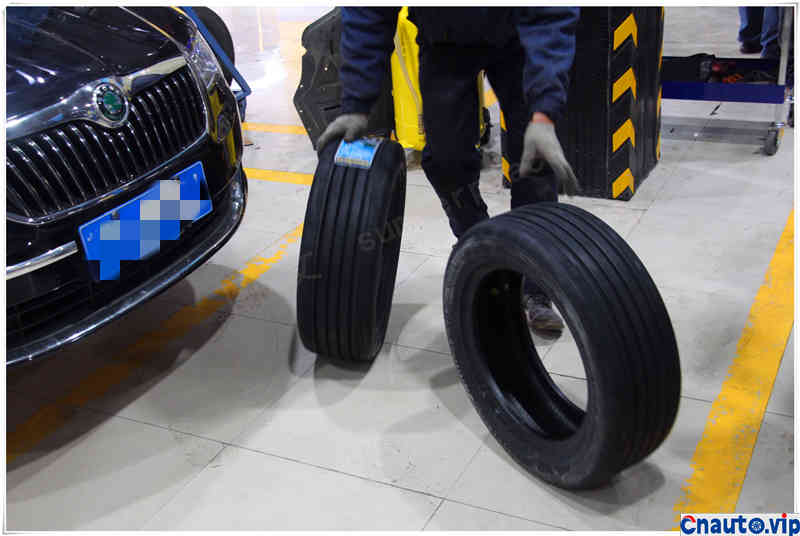

The store, not too far away from me, will arrive soon. Business here is good, and the store is a bit busy.

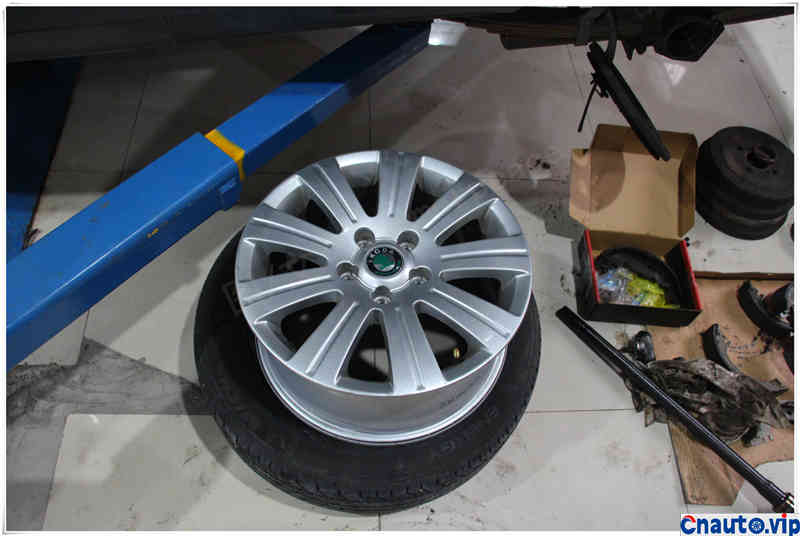

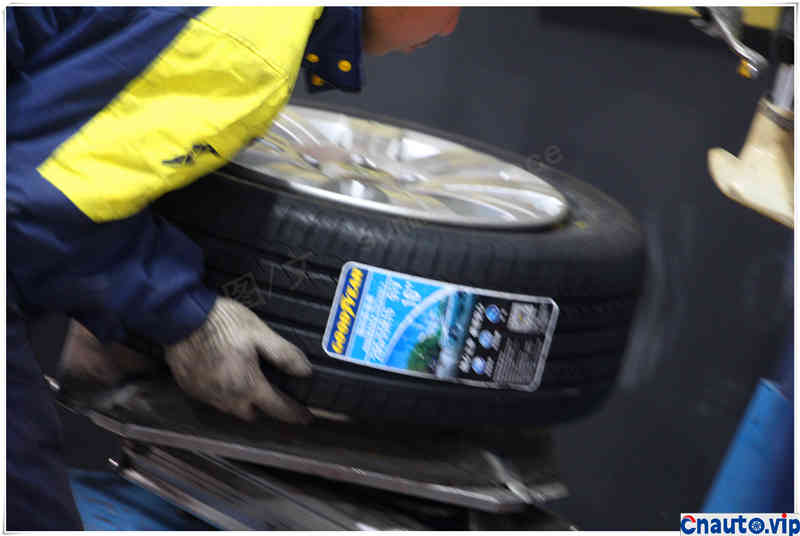

The boss drove my car into the store. Then, I asked the master to show me the four newly arrived tires. Let’s show it first. The model number is 205/55R16 Yiride, 91V, which matches my car exactly. The tire production cycle is 19 years, 20 weeks and 21 weeks, two respectively, which should be in May. Generally, tires need to be placed for several months to stabilize the rubber, which is just right.

The texture of the tire is interlaced with horizontal and diagonal, which is suitable for different road conditions. There are four drainage grooves in the middle, which effectively prevents “slip” in rainy days.

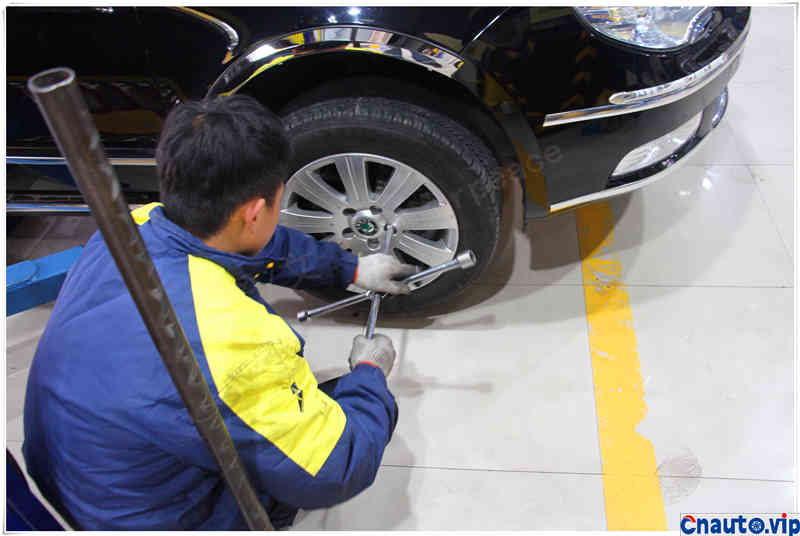

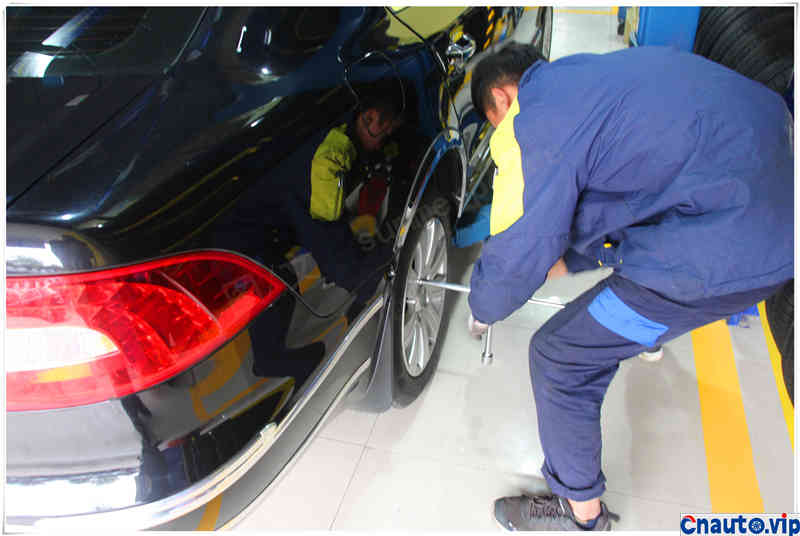

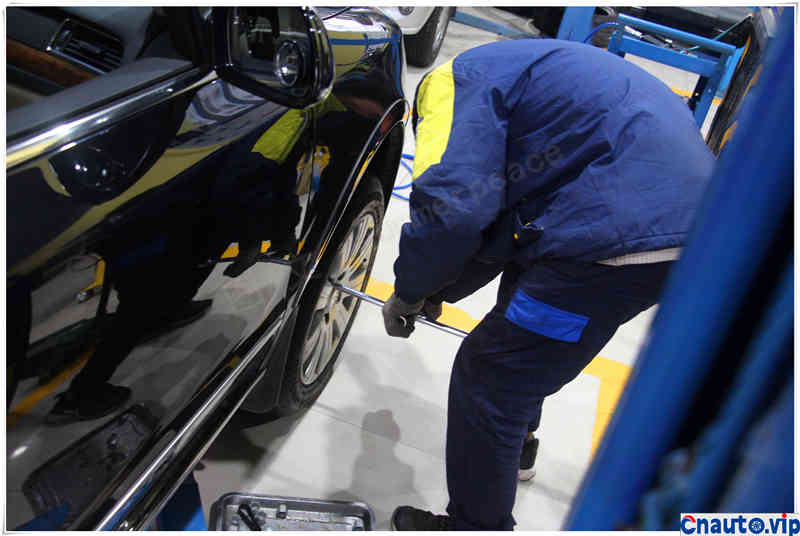

Next is the specific construction process. Young master, remove the wheels of the original car first. I reminded you to use Haorui’s special clip to remove the plastic cap.

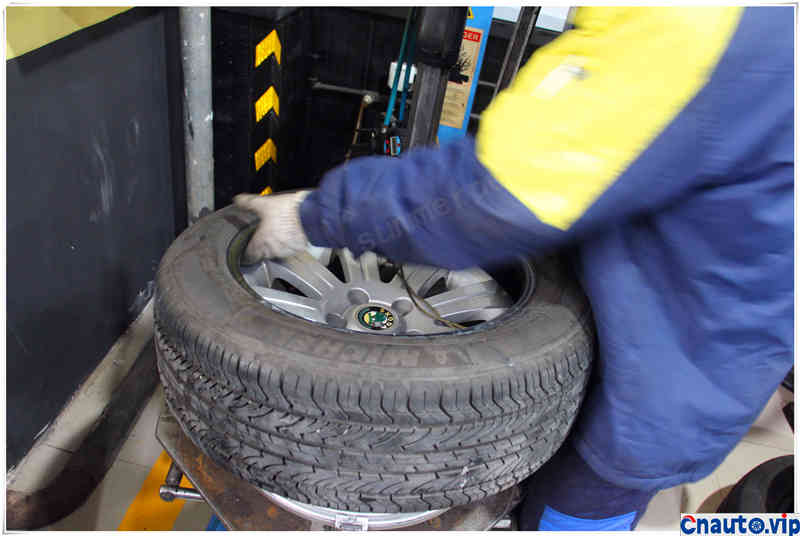

After removing the wheel, the master began to scrape the tire. Deflate first, then use a special tool. Every time a master removes a wheel, he puts the wheel hub on the old tire to avoid bumping the wheel hub directly on the ground. The entire process was operated in a standardized manner and the wheel hub was not damaged.

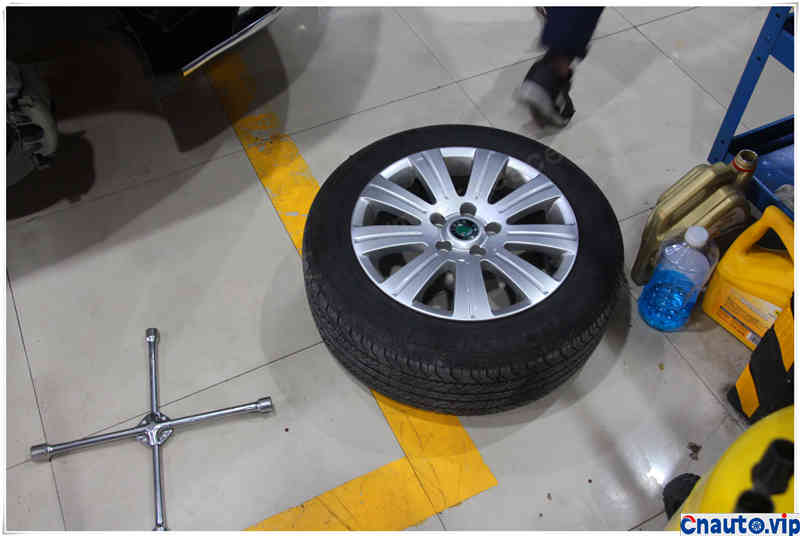

After the demolition was completed, a young master came to help at this time. First use a steel wire ball to remove the rubber and oil stains on the wheel hub.

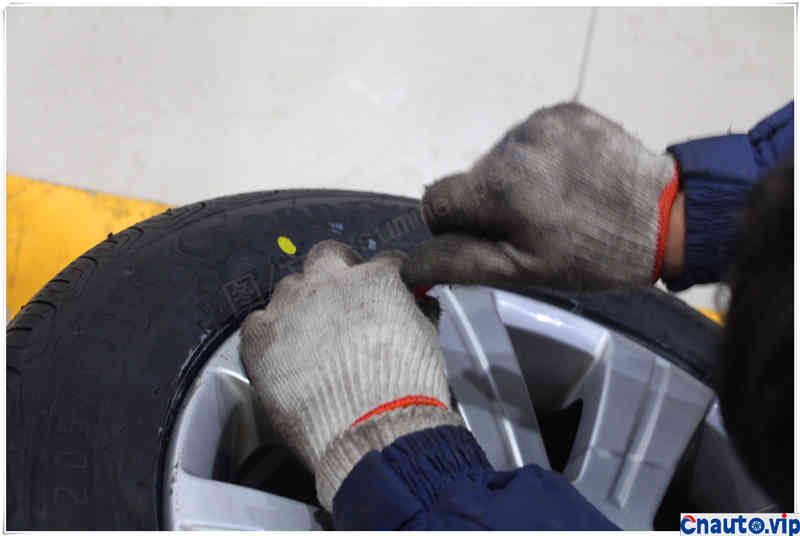

Then the master rolled over new Goodyear tires. Two more masters put on tires, which naturally made it much faster. During the installation process, apply some oil to the edge of the tire to facilitate construction.

Soon all four tires were installed, and it was time to inflate. When inflating, you will hear a “snap” sound, which is the sound of the tire being held into the right position by the gas and contacting the rim of the wheel hub.

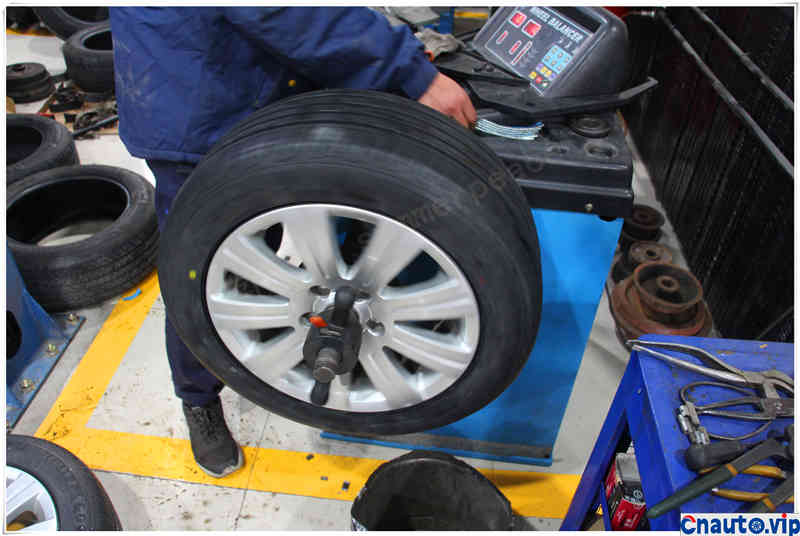

Then, the two of them began to check whether the tires were leaking, and then began to do dynamic balance after checking that there was no error. This is very necessary. After all, due to the structural characteristics of the wheel hub, the quality of each part is different.

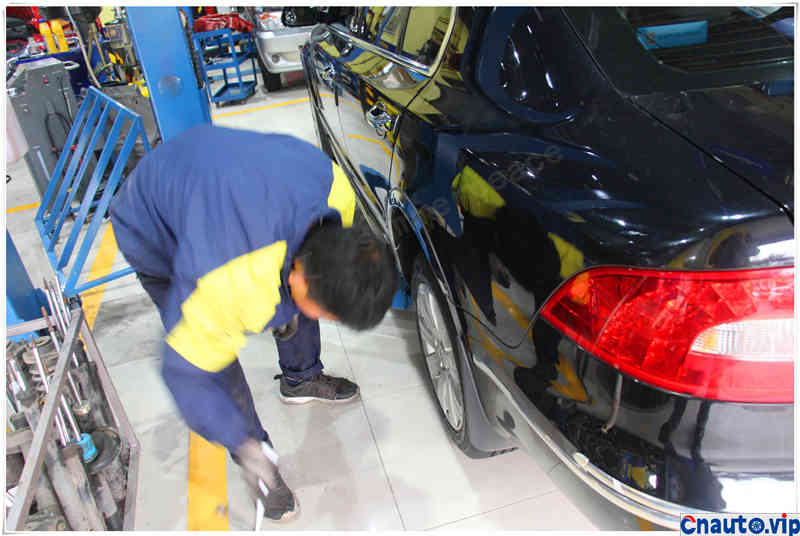

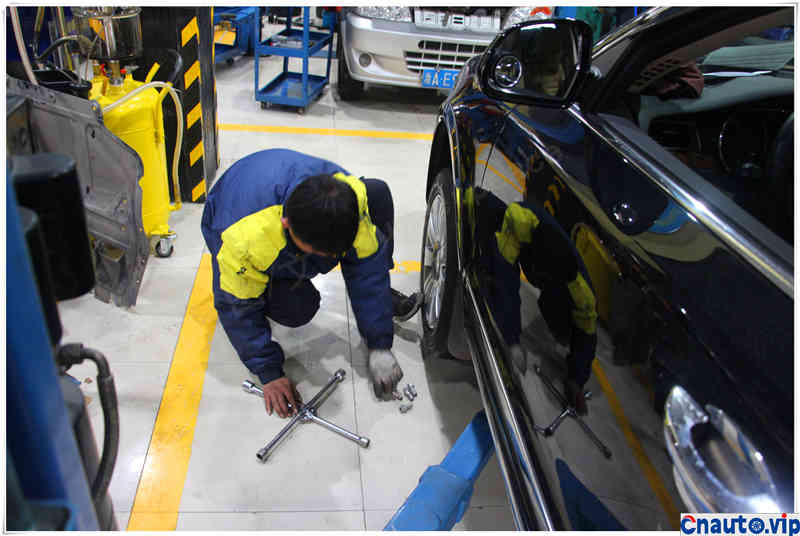

After finishing the dynamic balance, we began to load it back into the car. When installing it, the screws must be twisted diagonally, and then the car is lowered and the tires hit the ground. At this time, the screws on the tires are tightened and the plastic nut caps are installed.

This is how it’s done. Look, Hao Rui, who has put on Goodyear’s new shoes, is more energetic!

I drove the Haorui and walked for a while. When I started from a standstill, I felt a strong feeling of the tires grabbing the ground; during driving, it was very quiet; when braking, the horizontal grains and diagonal threads of the tires showed excellent friction.

April 1, 2024

April 1, 2024  March 27, 2024

March 27, 2024

March 27, 2024

March 27, 2024