[Flower Pepper Car Maintenance] Some precautions when disassembling and disassembling car oil bottom screws (to prevent oil bottom leaks)

Share some vehicle repair and maintenance cases from time to time. Let more people know some tips in daily car use, maintenance and testing. Know more about cars with cars!

Audi A4L comes to the store for major maintenance, which is great health care.![]() 6W km vehicle oil replacement operation, oil, three filters, spark plugs, inspection belt, oil change and so on.

6W km vehicle oil replacement operation, oil, three filters, spark plugs, inspection belt, oil change and so on.

But today’s story is not about the major maintenance of vehicles, but about a small screw.

But today’s story is not about the major maintenance of vehicles, but about a small screw.

As I wrote in the picture, the disassembly and disassembly of every screw of the car is not casual, a simple thing, if you ignore the key points, it will be compared to lose your temper and make you feel bad.

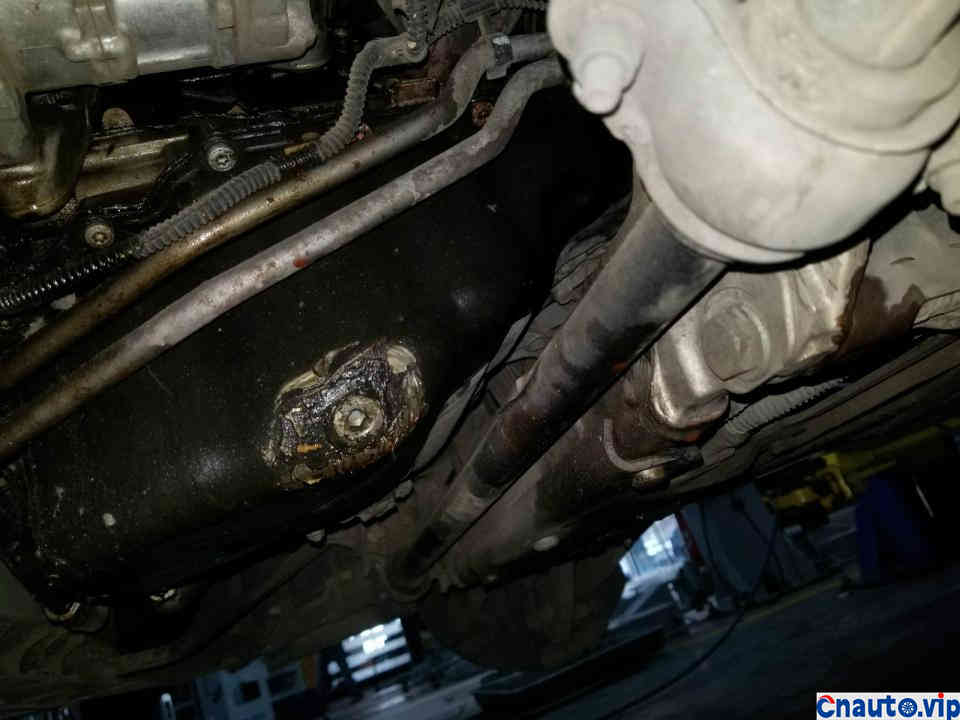

This is today’s protagonist-oil pan drain screw. (gravity oil discharge) We unscrew it every time we maintain it and let the oil flow out through the hole of this screw, which is the main function of setting this screw. Of course, some vehicle oil screws due to material problems and so on are not suitable for gravity, but the choice of pumping oil, here do not explain in detail.

It is obvious here that the oil is leaking at the oil bottom screw, and it should have leaked before it was very old, and the car owner has put a thick layer of glue here to plug the oil leak. The problem of oil leakage has been solved, but it has brought difficulties for the next disassembly and assembly of the oil screw, and the installation of the oil bottom screw will become more and more serious again and again (its tightening torque has changed, and you can only use more force to tighten it. More completely), and finally completely scrapped, can only be replaced with the oil pan.

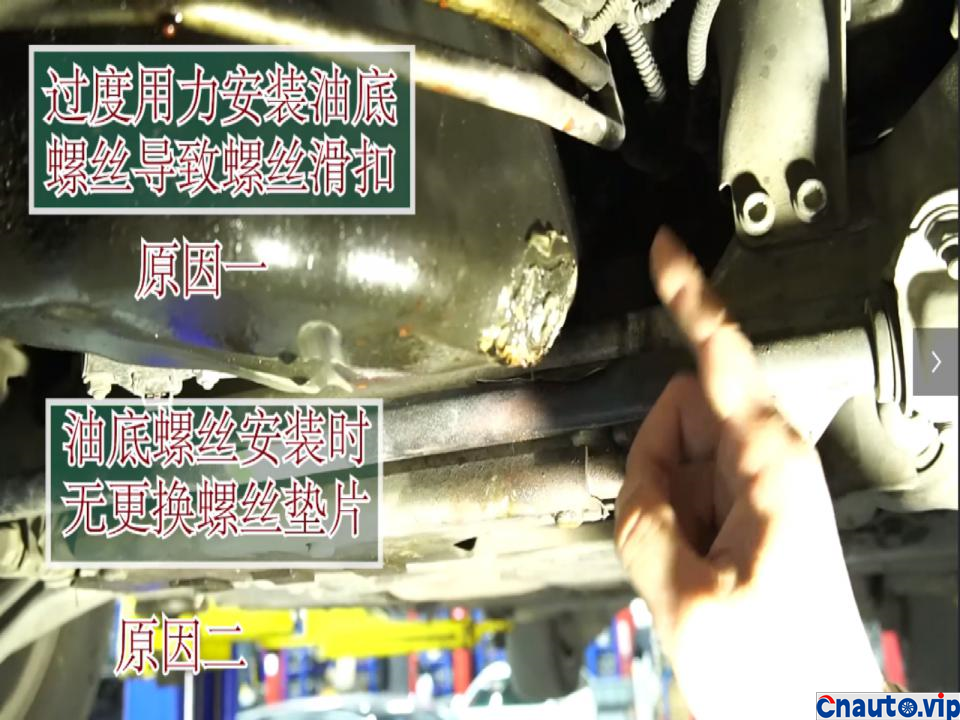

Most of the reasons for this problem are caused by improper operation. As for what reason let’s watch it together.

Here I list two reasons.

One: when installing oil bottom screws, they are not installed in accordance with the prescribed torque, and most of the time they are operated by hand feeling that they have been tightened. At this time, you may have exerted too much force, the screws are too much belt slips, or even elongated. Once the screw is lengthened, the sealing performance will be reduced, and then the oil may slowly seep out during your long driving, and when you maintain it, you may think that you did not tighten the oil last time. So this time you will better tighten it (glue, wrap a layer of film, etc.) and enter a dead cycle.

One: when installing oil bottom screws, they are not installed in accordance with the prescribed torque, and most of the time they are operated by hand feeling that they have been tightened. At this time, you may have exerted too much force, the screws are too much belt slips, or even elongated. Once the screw is lengthened, the sealing performance will be reduced, and then the oil may slowly seep out during your long driving, and when you maintain it, you may think that you did not tighten the oil last time. So this time you will better tighten it (glue, wrap a layer of film, etc.) and enter a dead cycle.

Two: when we disassemble the oil bottom screw, we will find that there is a small gasket at the oil bottom screw. Yes, he is also one of the culprits. Under normal circumstances, we need to replace this small gasket every time we remove the oil bottom screw. But very often you forget its existence (or even ignore it) and do not replace it. Finally, there is an oil leak because of its uneven force. There are also some rare reasons for which you are welcome to add.

Oh, by the way, some external factors also exist, but this is an example, that is, the so-called accident, which we can’t prevent, so we can only remind car owners to drive carefully.

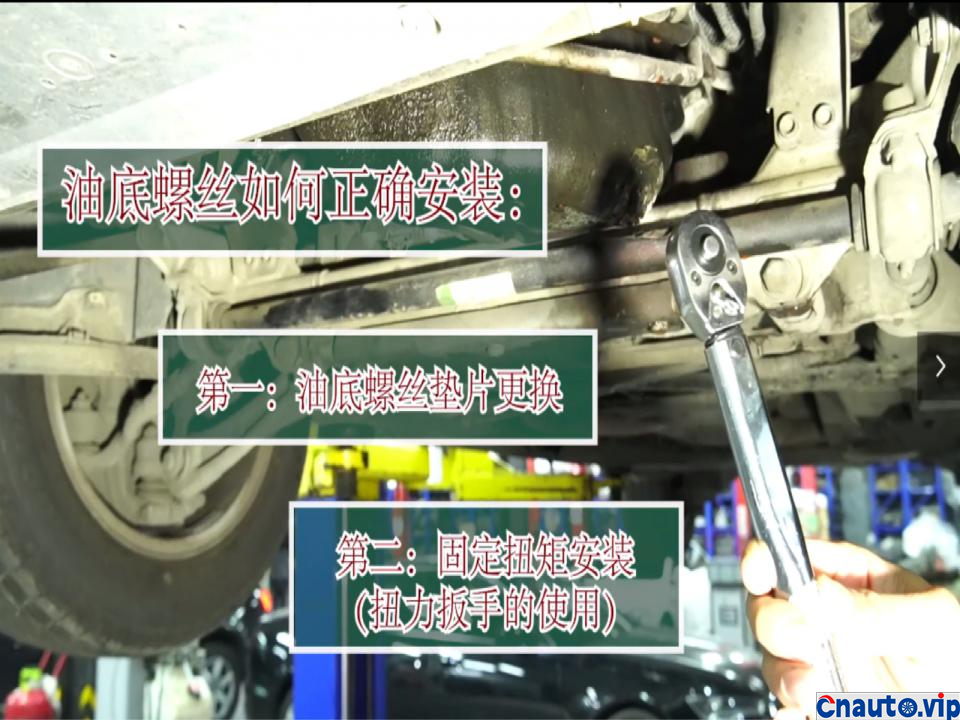

With regard to the installation of car screws, what we recommend here is the torque wrench. Adjust the fixed torque and click to install it.

Torque wrenches are divided into three types: large, medium and small, and some of them are semi-hung according to different vehicles.![]() Some pickups and some cars depend on your use, which is convenient to buy.

Some pickups and some cars depend on your use, which is convenient to buy.![]() . No kidding, it’s almost over here.

. No kidding, it’s almost over here.

Torque wrenches are divided into three types: large, medium and small, and some of them are semi-hung according to different vehicles.

Finally, remind car owners: after moving the car oil screws, please try to do these two points in my picture, if you do not have this condition, you can not force it, it can only be anti-microcosmic!

Thank you for watching! It’s over.

Thank you for watching! It’s over.

Hot Information

Tesla Autopilot and similar automated driving systems get ‘poor’ rating from prominent safety group

April 1, 2024

April 1, 2024 Localization of EV parts without production scalability may not help cut EV price, says President, Amara Raja

March 27, 2024

March 27, 2024

JCTSL may turn bus stands into charging points for e-buses

March 27, 2024

March 27, 2024 You May Like