[Unboxing every day] Dismantling and maintenance of Zhonghua Zunchi’s speed sensor without signal upshifting and slipping phenomenon

This is a project on gearbox disassembly and repair. Here are different processes for dismantling and repair car gearbox problems. I look forward to everyone’s reading and comments.

The car that came to the store for repair today is a 2011 Zhonghua Zunchi vehicle. It is a 1.8T automatic comfort model equipped with a 5-speed automatic manual transmission (AMT). According to the owner, the speed sensor has no signal and the internal upshifts are slipping.

The car that came to the store for repair today is a 2011 Zhonghua Zunchi vehicle. It is a 1.8T automatic comfort model equipped with a 5-speed automatic manual transmission (AMT). According to the owner, the speed sensor has no signal and the internal upshifts are slipping.

Kilometers traveled: 42118 kilometers.

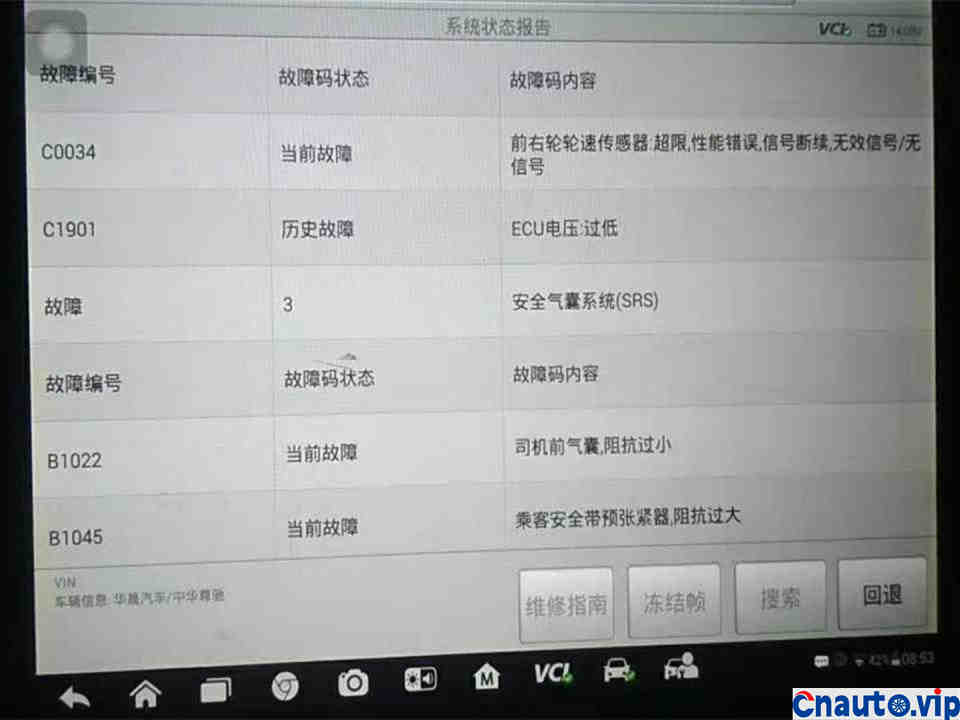

Connect to a computer to detect fault codes;

Open the cabin for inspection and prepare for maintenance;

Remove the power supply;

Remove the air intake pipe;

Remove the chassis on the shelf;

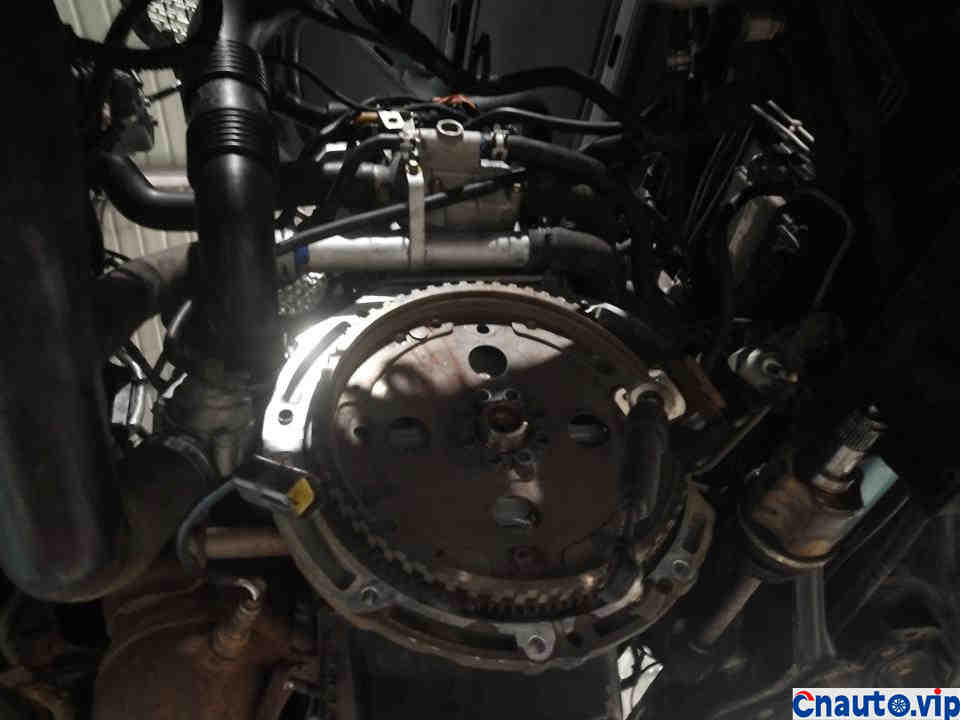

Chassis;(engine on the left, gearbox on the right)

Remove tires;

Remove the oil valve bolts under the gearbox to prepare for draining oil;

Drain internal transmission oil;

Remove the transmission connecting bolts;

Detach the gearbox and prepare to remove it;

Falling gearbox;

The cabin after removing the gearbox;

Separated couplers;

Put it on the workbench and prepare to disassemble the gearbox;

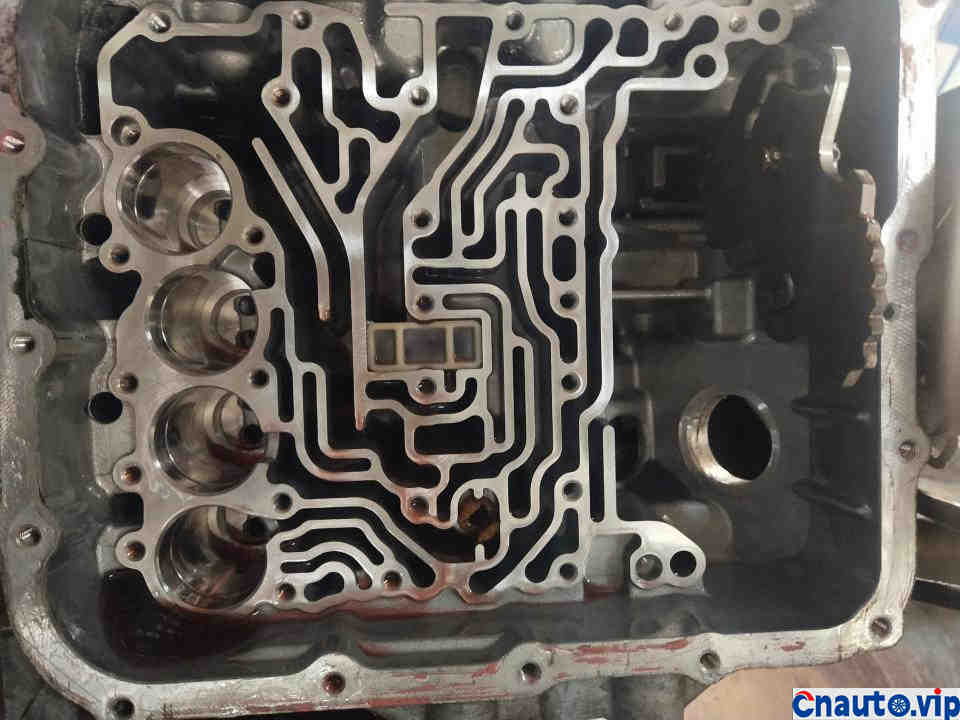

disassembled oil pan;

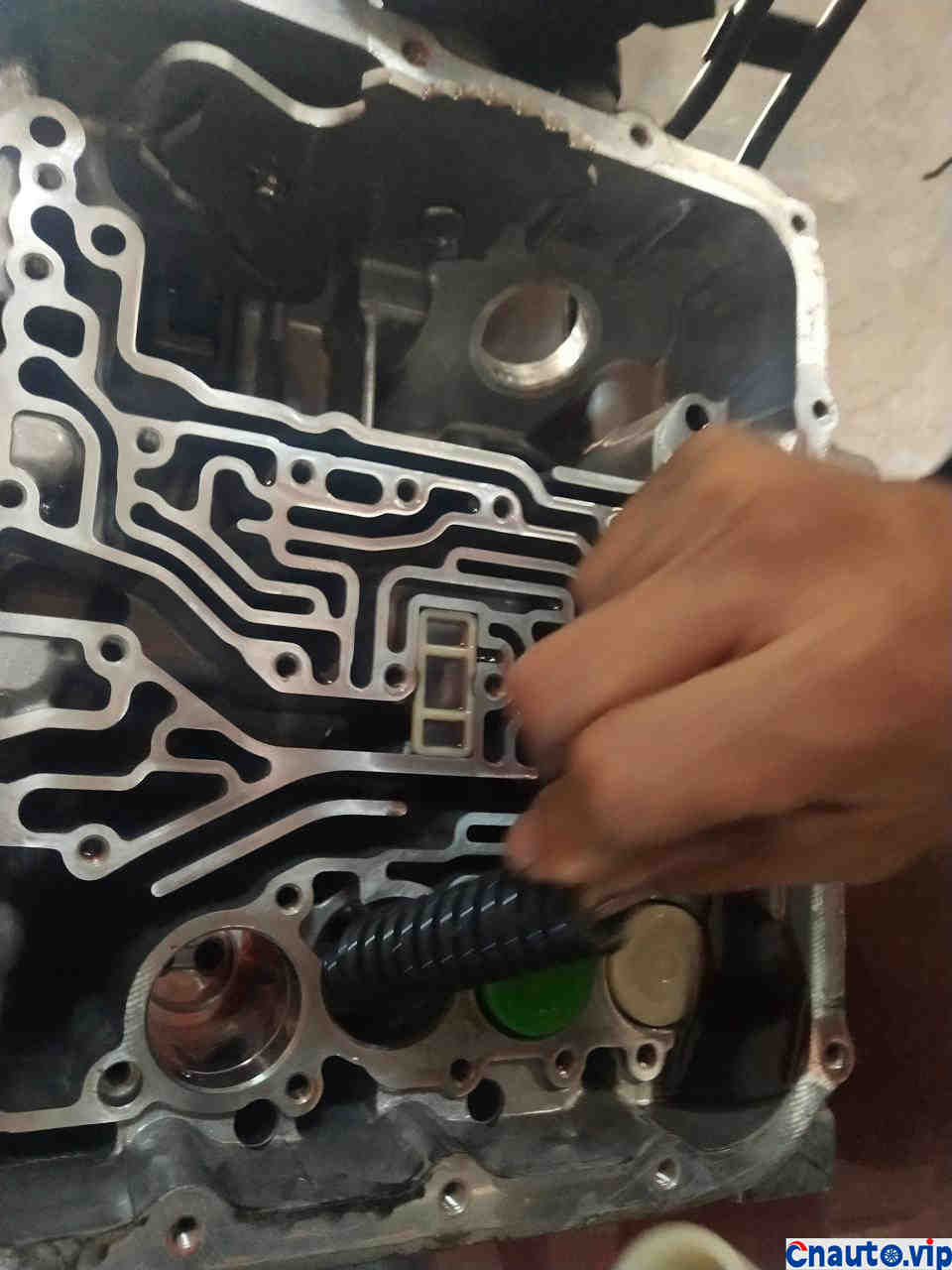

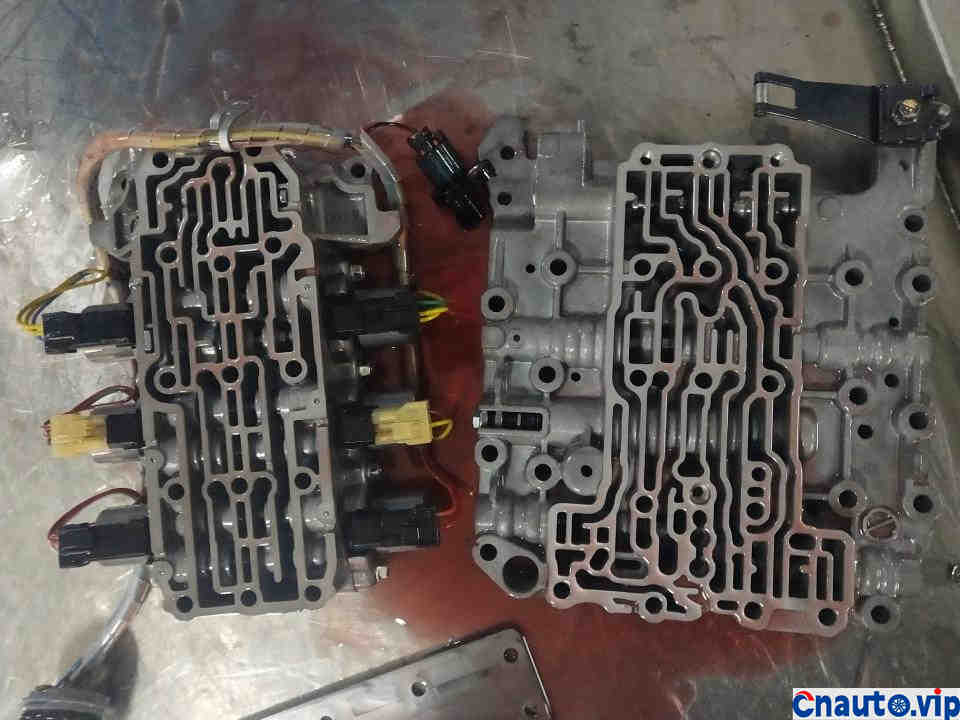

Removing the valve body electromechanical;

Disassembled valve body electromechanical;

Removing the accumulator;

Remove accumulator;

Remove the accumulator;

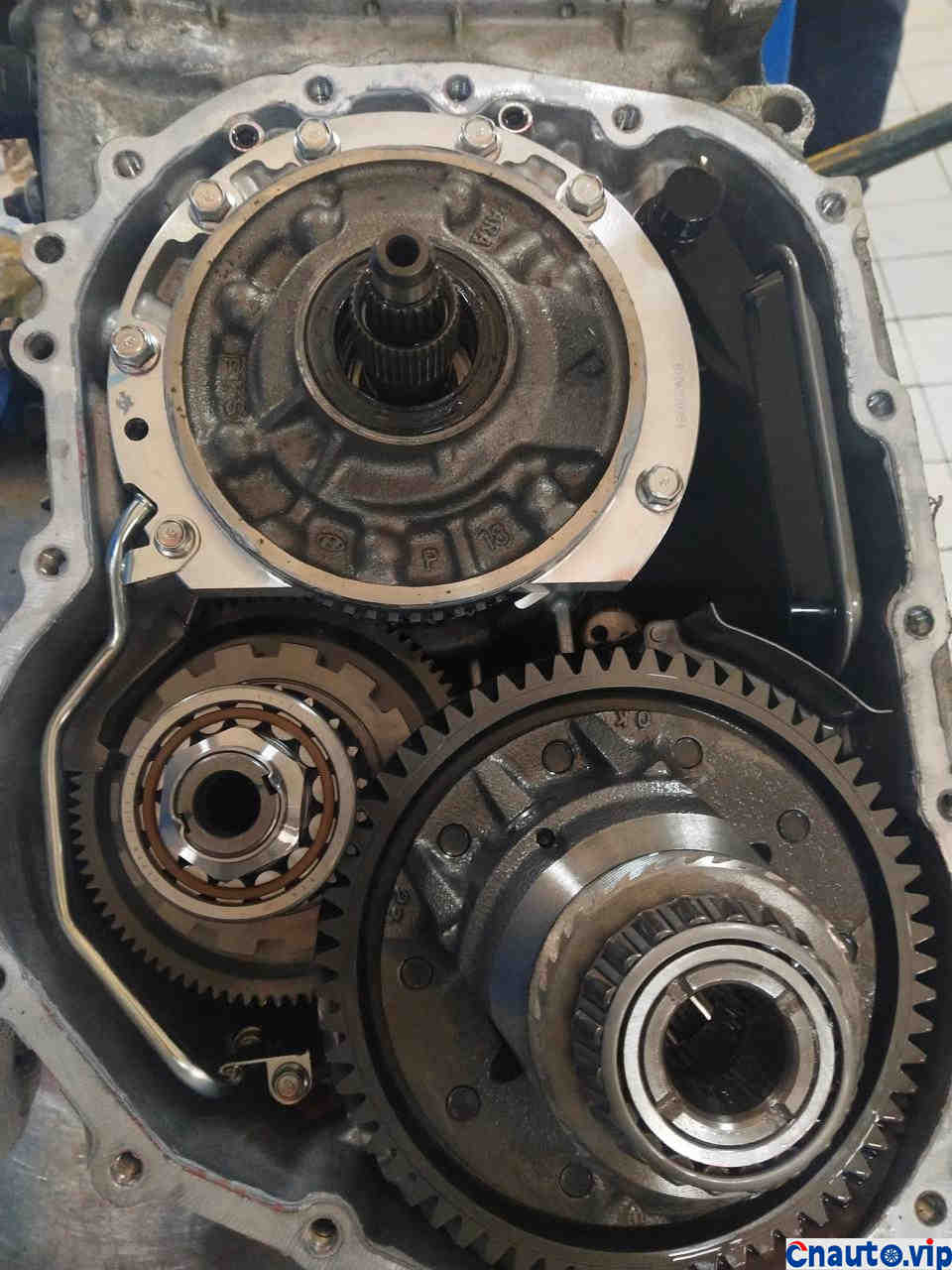

Remove the front shell of the gearbox;

Removed oil compartment;

Oil pump base;

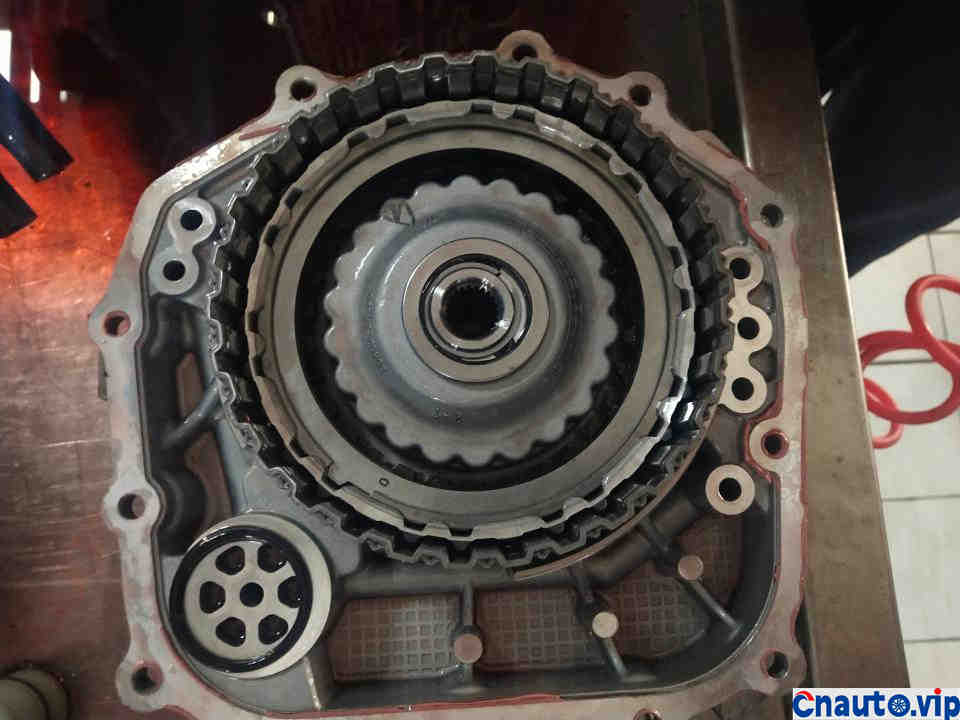

Worn friction discs;(need to be replaced)

disassembled gearbox parts;

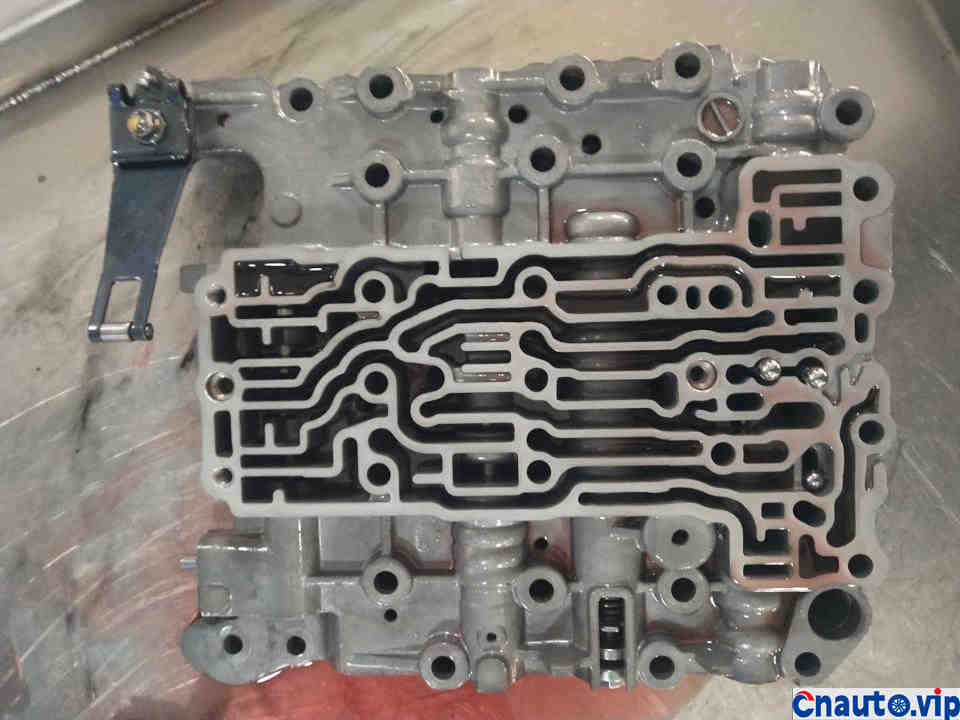

Disassemble the valve body for electromechanical maintenance;

Dismantling and maintenance;

The master tested that the back cover drum was relieved;

Rear cover drum replacement;

Assembly on the rack;

This gearbox disassembly and maintenance mainly involves pressure relief from the rear cover drum, valve body repair, and internal friction discs are worn; then the internal parts are cleaned and the gearbox oil is replaced. After the assembly is completed; after the master test, the fault is cleared.

Friendly reminder: When the vehicle is in use, if the vehicle feels frustrated and locks up, in serious cases, it will lead to failures such as not moving, high fuel consumption, and poor shifting quality, which will directly affect traffic safety and threaten the safety of the driver and the passenger. Therefore, during the daily maintenance of the car, the safety issue of the automatic gearbox must not be ignored.

Friendly reminder: When the vehicle is in use, if the vehicle feels frustrated and locks up, in serious cases, it will lead to failures such as not moving, high fuel consumption, and poor shifting quality, which will directly affect traffic safety and threaten the safety of the driver and the passenger. Therefore, during the daily maintenance of the car, the safety issue of the automatic gearbox must not be ignored.

Hot Information

Tesla Autopilot and similar automated driving systems get ‘poor’ rating from prominent safety group

April 1, 2024

April 1, 2024 Localization of EV parts without production scalability may not help cut EV price, says President, Amara Raja

March 27, 2024

March 27, 2024

JCTSL may turn bus stands into charging points for e-buses

March 27, 2024

March 27, 2024 You May Like