Moderator, please ask me a question about the heater (attach the maintenance process).

Hello, moderator, opened several times today, before the warm wind is very good, now feel the warm wind is not hot, touch the warm air pipe is hot, the warm air return pipe is not too hot. Moderator, do you have a waterway map of the 212 heating air system? Could it be that the pipe is blocked, or is there a valve that can’t be opened?

Thank you in advance, and I wish the moderator and everyone a happy New year! Business is booming!

Thank you in advance, and I wish the moderator and everyone a happy New year! Business is booming!

The warm wind is not hot, so I didn’t want to fix it, but the car won’t drive anyway.

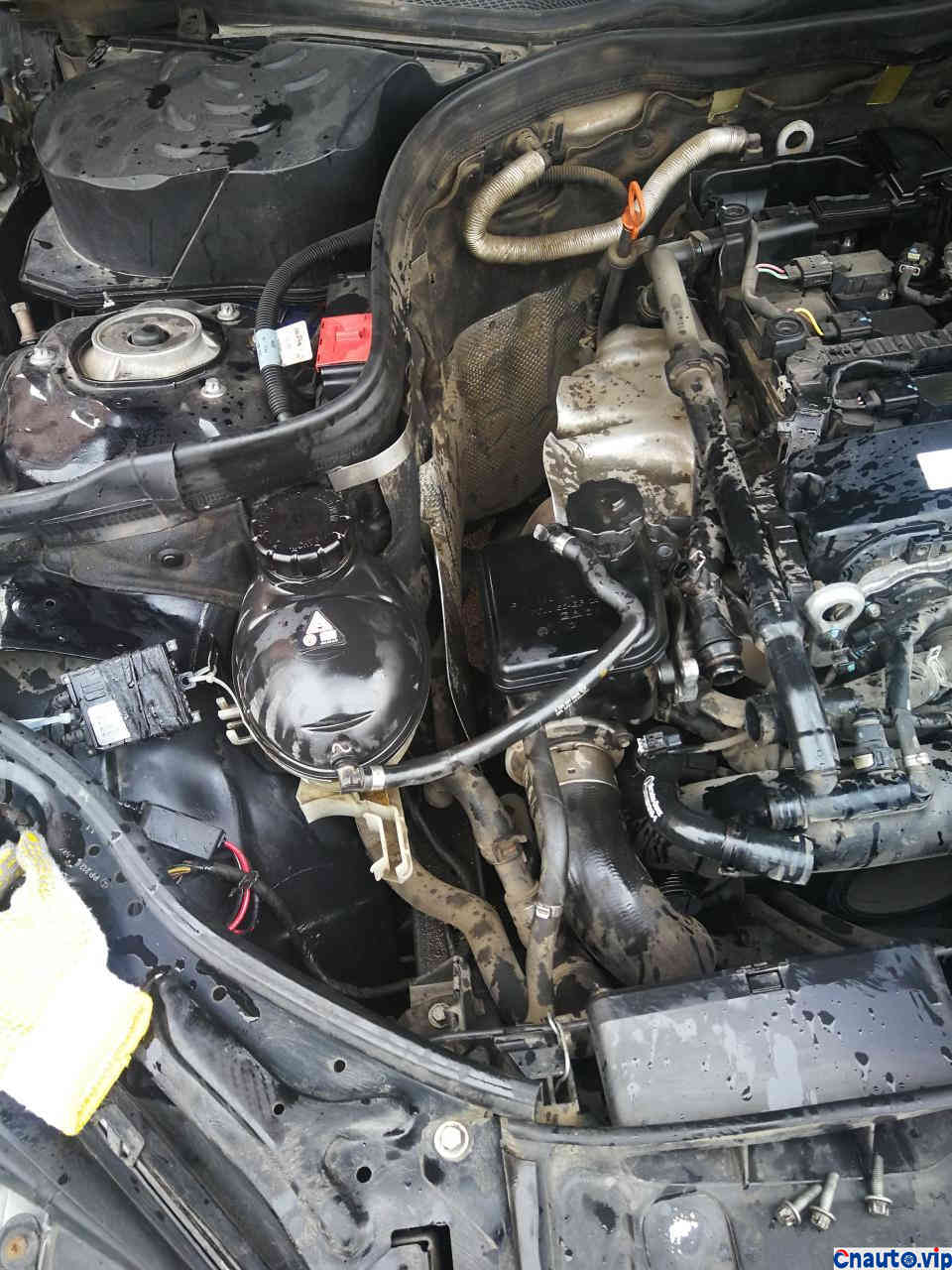

For well-known reasons, I decided to do it while I stayed at home during the Spring Festival. According to the advice of the moderator and the students, first try to see if the small water tank is unobstructed. When you blow from here, you can see the antifreeze coming out of the overflow kettle very smoothly. Eliminate the blockage of the small water tank.

For well-known reasons, I decided to do it while I stayed at home during the Spring Festival. According to the advice of the moderator and the students, first try to see if the small water tank is unobstructed. When you blow from here, you can see the antifreeze coming out of the overflow kettle very smoothly. Eliminate the blockage of the small water tank.

Thanks to the moderator and the indescribable reminder. So I decided to take a look at the solenoid valve. In order to make it easy to dismantle, I first earned a circle in the community. Heat it up a little bit. Carelessly, I didn’t unscrew the lid of the kettle. The warm air pipe spurts a lot of antifreeze. Ow, my antifreeze. If you unscrew it, it will flow from the small pipe into the kettle.

You can see it when you open it. This valve is crooked. It’s stuck around the corner. As a result, sometimes some thermal antifreeze passes through, there is a little warm air, sometimes it is completely blocked, and there is no warm air at all. So it’s hard to judge the point of failure.

A black coil that generates magnetic force for electrification. Completely airtight.

Inside this is the rod of the valve.

You can see that the pole of this plug is broken.

It should be inserted in the hole on the right, and the rod is connected. Now, when the rod is broken, it will not move when it retracts (opens the valve). Making it impossible for hot water to pass.

This is normal. If the pole isn’t broken.

A normal family photo.

Now the family photo.

If you want to connect the broken pole from the front, it’s not easy to do it. If you hit the hole, it’s too deep. Decided to start with the ass. Open it.

The steel file was filed a few times and the kitchen knife cut it. It’s very thin, and it opens at once.

This is the pole that broke. The pole was inserted in an iron dune. When the shell is electrified to produce magnetic force, the iron dunes will move. A real solenoid valve.

We have to connect it.

I got it with glue.

File flat at the joint, making it easier to move up and down.

After an experiment, it was so sticky that it opened as soon as it was broken. I decided to punch the hole and use the mortise and tenon structure. The electric drill seems to be difficult to control.

Use a crane grinder, this is more fine.

It went well in the eye. It’s not broken.

I planned to connect with a cotton swab rod, but later I thought that if antifreeze came in, it would soak, and this bamboo might not work for a long time.

Bamboo sticks have been eliminated.

The aluminum sheet used, cut well, interference fit. File some holes in the edge, make thorns, heat the windproof lighter, put some glue in the hole, and insert it.

Insert one end of the left hand first, and also deal with the right hand end.

Got it. It’s solid.

File at the joint.

Waiting for the final assembly.

What should I do with this missing ass? This is a seam sealed with glue, and then the butt is sealed. After hanging for a whole day, I feel that the intensity is not strong enough. So I wrapped it with raw material. Later, I wanted to use solder again, but I felt that I was not sure of soldering, and the 600 watt iron head of the unit was broken and could not be used because it had not been repaired. Decided to use physical methods. Raw material belt and bottle cap.

This rubber ring was useless later.

Apply sealant for car repair to seal a large circle around it. The raw material belt wrapped inside in the middle is very strong as soon as the screw is tightened.

Close the lid and tighten the hoop. The lid is just the right size.

Finished product.

The plastic bottle cap is right to the bottom. The error of thickness is less than 1 mm.

It’s loaded. It doesn’t look good. I’m going to try it sometime, as long as I don’t miss it.

Thanks to the moderator boss, XUCHENGHONG911, braised Page, can not describe the strong support of 2017 and the concern of the students, I do not know whether the repair can be used, I will try for a period of time to report the use.

I wish the moderator and all enthusiastic students a good meal, a good drink, a good home, no fever, no cough, and a smooth passage!

Thanks to the moderator boss, XUCHENGHONG911, braised Page, can not describe the strong support of 2017 and the concern of the students, I do not know whether the repair can be used, I will try for a period of time to report the use.

I wish the moderator and all enthusiastic students a good meal, a good drink, a good home, no fever, no cough, and a smooth passage!

Hot Information

Tesla Autopilot and similar automated driving systems get ‘poor’ rating from prominent safety group

April 1, 2024

April 1, 2024 Localization of EV parts without production scalability may not help cut EV price, says President, Amara Raja

March 27, 2024

March 27, 2024

JCTSL may turn bus stands into charging points for e-buses

March 27, 2024

March 27, 2024 You May Like