I. the battery of the original car

There is no need to say much about the advantages of the 17 models since they were bought. The disadvantage mentioned in the forum is that the ① auxiliary battery is easy to run out of power and the system cannot start ② many times. Short distance engine oil is easy to increase except that ① is not touched, and ② is not so obvious after updating the ECU firmware. But there was a problem during the outbreak, ①. The 12V auxiliary battery on the right side of the trunk of the car’s 12V auxiliary battery is originally equipped with Jiangseni, Delkor series, model CMF40L-BCI, with a capacity of 40Ahmin CCA354A. In fact, the maximum current demand of extremely small lead-acid batteries is no more than 150A, and the fuse connected at the back of the positive pole of the battery is 150A. Recently, under the influence of COVID-19, the car drove less, and the battery lost power after two and a half years, and the car could not be started at the beginning of a week. After starting twice with an emergency start battery (immediately bought a 12V emergency start lithium iron phosphate battery after the old scalper said about the car battery), he simply couldn’t open the door with a smart key for three days. At least he studied the door opened by a mechanical key for a long time.

Ma Bao looked for this battery, the original model is more than 1K, the alternative version is mostly 36~38Ah, the price is basically around 350, there are occasional 40Ah, but are more expensive, 800 or so.

Affected by the forum, after buying a car, I bought an emergency start battery, lithium iron phosphate. I haven’t had a chance to use it all the time, but I finally used it this time.

The battery of the original car was produced on March 26, 2017. On February 4, 2020, the battery failed to start for the first time. After the emergency start-up battery was powered on 2, it was found that the number of days that could be parked was even more reduced.

II. Theoretical study and research

In fact, since the first car in the family began to change the battery (the bright sharp in February 2013, the original car is the Valta 60Ah), I always wanted to replace it with lithium iron phosphate battery, but I couldn’t find a suitable or reliable lithium iron phosphate battery, and now I use the third battery.

The 12V lead-acid battery consists of six cells in series with a voltage range of 10.8 to 13.2 V. 90% of the discharge curve platform, 10% of the electricity is 12.2 to 11.7 V.

The voltage of 12V automobile generator is 14.50.25 V according to the national standard (in fact, the electricity generated by the generator is alternating current, which is rectified into direct current, 14.5V is only a valid value, and the actual peak voltage is as high as 20.5V).

4 Lithium iron phosphate battery voltage range is 9.4V~14.6V, discharge curve platform 90% 10% electricity is 13.2-12.8V.

Which is better or worse, we can Baidu, the biggest advantage of lithium iron phosphate is that the life is 4 / 7 times longer than lead acid, the discharge voltage platform is high, the charge and discharge speed is fast, and the weight is 50% and 70% lower than lead acid.

What we use is not a generator, but a low-voltage DC converter called LDC (DC-DC converter) that directly converts 240V high voltage to 12.8V-15.1 V DC to charge the auxiliary battery, which happens to be used for lithium iron phosphate batteries.

I have also seen a hero directly use 4 series of capacitive lithium iron phosphate cell to make a car start battery without a protective board (the kind of engine of a generator, which is said to be fine after 3 years). But considering the life and safety problems, I still need to use a protective plate (after all, I don’t want the above direct 4-string god to have the energy to measure whether the voltage and internal resistance of the cell are consistent, and can eliminate hidden dangers).

Third, self-made ideas

Taking advantage of the epidemic to go to work late, I began to plan to buy my own battery assembly. From the battery shell, lithium iron phosphate cell, protective plate, heat sink, connecting copper sheet, copper bolt, heat conduction silica gel, glass fiber insulation board, copper wire nose, all searched all over, basically settled.

Tell me what you think:

1. Due to the limitation of the shape and size of the battery, the external size of the battery box is suitable for 198X128X200 (220C), and the internal size is limited to 184LX117wide X179 high (price 72.5). The cell has been looking around on Mabao for a long time, not because the charge and discharge current of the second-hand battery is too small (mainly the charging current, mostly recommended 0.1C, according to the cell of 75Ah, it is 7.5A, can not be used directly), but the size is not suitable. Until occasionally found a new 20Ah A123 cell, size 150X140X14, internal resistance less than 0.5m (59 / chip). This shell can be put into 8 pieces, 2 and 4 strings are just right, the key is to support 30C continuous discharge, 2 and up to 1200A, short-time discharge support 50C, but also reached 2000A you can stand it! There is a gap of 34mm on one side of the long end, and the protective plate and heat sink are enough. There are 12V start-up battery and 48V light hybrid battery module specially for cars on A123’s official website, so I still trust A123’s battery. Another idea is to use four strings of 105Ah Li energy (single cell size 130X36X200, supporting 1C charging and 3C discharge) without shell assembly.

2. Protection board: find a 300A same port protection board for automobile startup (unit price 300), the continuous charge and discharge current can reach 300A, and the discharge current can reach 1500A in a short time.

3, other copper bolts, thermal conductive silica gel, heat sink have found the link (a total of 50). The copper connection sheet and fiberglass board are all machined (80). Together with some other connecting wires, solders and so on, the overall material cost is about 1000 yuan.

Everything is ready to add a shopping cart, ready to place an order.

IV. Accidental discovery of finished products that meet the requirements

In the second solution, that is, four strings of 105A billion lithium energy monomers (this cell can be charged at 1C, discharged at 3C, 4 strings of 144X130X200, plus the height of the connecting screw 205mm, the end 144plus the protective plate 7mm can also be added to the heat sink, the width direction can not fit into the battery box mentioned above, but it can be installed into the extremely small battery position, which is intended to be wrapped with polyimide tape. The advantage is that it can store 1.2 kilowatt-hours of electricity (almost catch up with the storage of high-voltage batteries), and you can use a high-power inverter to boil water and cook) when looking for that kind of brass 19mm and 17mm battery pole (this thing is not easy to find at all), I occasionally find that his home also makes a start-up battery that claims to use A123System cells, and the price is more favorable. Communicate with the store and say that it is used for military products, but the only pity is that the pole column of this type of battery is a small pillar of the national standard. The price is a little cheaper than making it yourself. After careful communication, I hesitated to issue an order and tried to buy a piece. During the epidemic, both the store and the express delivery were quite powerful. After receiving the goods, I did a charge and discharge test. There was basically no temperature rise during charge and discharge, and the capacity basically met the requirements. The voltage measured before loading is 13.28V.

The battery pole which is intended to be matched to the second scheme has a bolt hole at the bottom.

After receiving the goods, the 4.5kg was less than (forget the specific number, using the kitchen electronic scale of the measuring range 5Kg, forgot to take pictures at that time), and carried out a simple capacity test, no 12V high-power appliances, cut off two sections of electric furnace wire in parallel, the measuring instrument is relatively simple, and the nominal capacity can reach 80% + for protection.

Fifth, the installation process and the solution of the pole problem

1. ① first removes the three Phillips screws in the red circle at the bottom of the trunk; ② removes the side baffle, which is clasped, just pull it to the side.

2. Remove 3 fixing bolts for ① and inner hexagonal sleeve and remove the cross-shaped fixing steel frame. ② removes the positive and negative terminal with an inner hexagonal sleeve. ③ removes the old battery and replaces it with a new one. ④ restored cruciform fixed steel frame. ⑤ restores the side bezel and the bottom partition.

Use the installed picture when removing the old battery without taking a picture. The hose for deflation is no longer needed, as long as there is no sound in the waves.

Because the pole column of lithium iron phosphate battery is brass, at the beginning, a conical spring sleeve was wrapped with 6mm2 single copper wire (diameter 2.7mm) and placed on the pole, because the brass surface is not like lead, which is soft and easy to deform and get stuck, the brass surface is smooth and hard, and the taper is still very sharp at 1:9, it is very easy to slip, and the spring sleeve is easy to slide upward when tightening the positive and negative pole clamp. Later, I went to a non-ferrous metal store to buy a small section of 18X2 copper tube, processed it into an open sleeve, put it on the battery pole, and barely stopped slipping. In fact, it is recommended to use brass pole manufacturers, no longer according to the national standard 1:9 taper to process brass pole, I think directly take the diameter of the middle height of the cone into a cylinder (the specific size is said in the appendix).

Positive pole column, 6mm2 copper single core wire winding. Pay attention to that 150A fuse.

VI. Use effect

After loading, it ran for about 1 hour and 30 kilometers, and the measured voltage was 13.32V. At present, it has been stable between 13.22 and 13.66V. When the engine starts, the sound becomes lower (the analysis should be that the voltage is higher, the ignition is more sufficient), and the running time of the cooler becomes shorter (in the past, after pressing the brakes on Power, the engine runs for about 5 minutes, but now it stops for 2 minutes, it should be that the high full voltage of the small battery will give a signal to the LDC, less charging to the small battery, indirectly reducing the engine load, notice that the environment is basically the same, all in the basement. The temperature is relatively constant, and the influence of coolant temperature can be ignored.

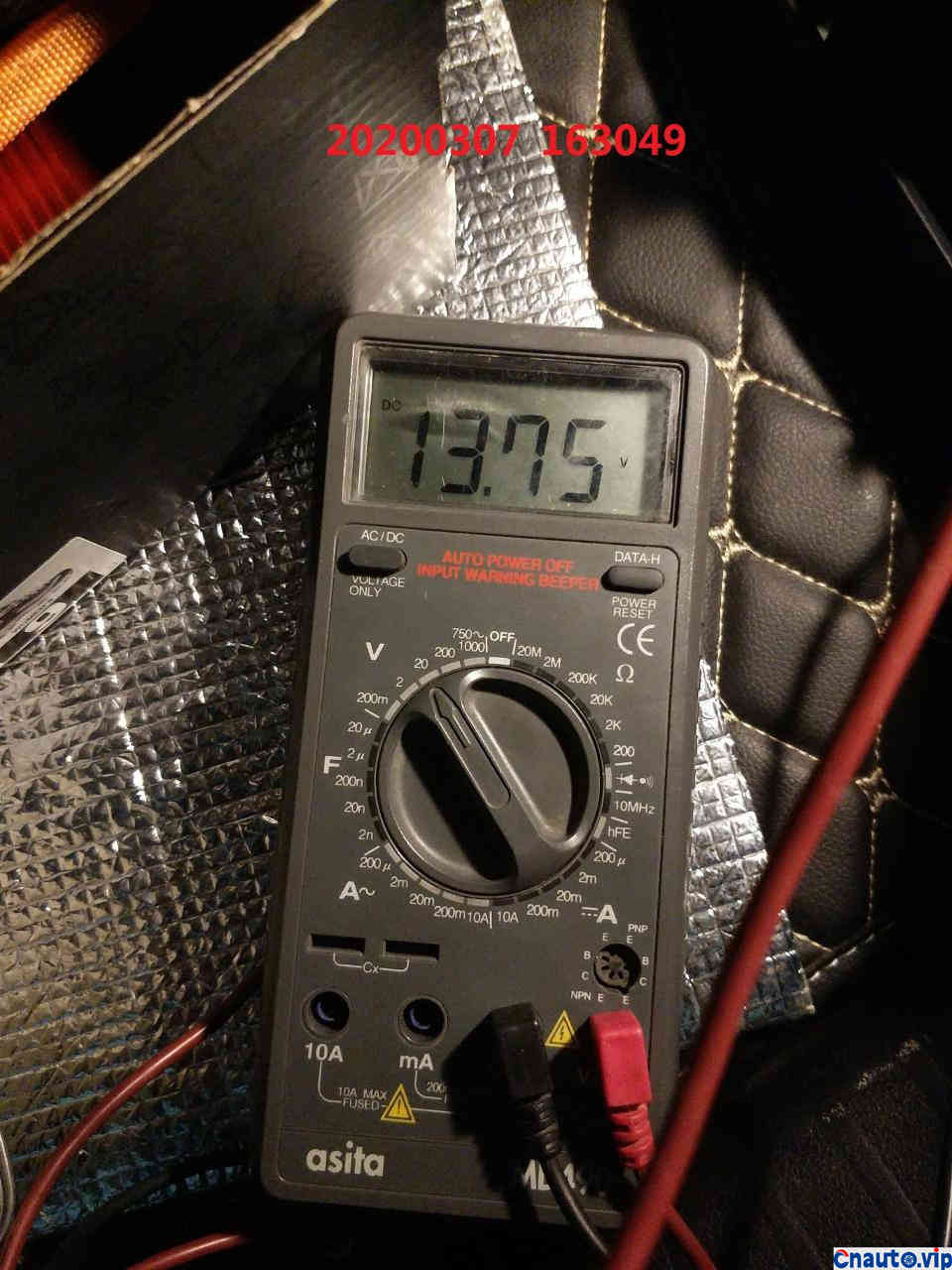

The auxiliary battery voltage instability or charging logic problems that have been widely discussed before, and the fuel injection lag caused by voltage instability tested by Lao scalper (unfortunately he quit our forum) led to the problem of increased oil (Lao scalper has been looking for a lead-acid battery with a battery standby voltage of 13V, but without a great god of practice) can only rely on later to experience slowly. But for these times, the initial voltage is 13.32V, the voltage after unlocking the door for 7 days is 13.25V, and the voltage after Ready is 13.75V. If the fuel injection lag mentioned by the old scalper occurs when the voltage is lower than 12.1V (I can’t remember exactly how much V he said, a well-remembered warrior told me), I will pay attention to the subsequent oil level measurement (this article will not elaborate on it).

After installation and running for more than 30 kilometers, lock the pre-test voltage of the car. The timestamp on the picture is the file name “IMG_20200301_124753.jpg” of the referenced phone photo.

The voltage measured after opening the door after parking for a week.

The voltage is measured after landing.

7. Suggestions for everyone

Because the platform voltage of lithium iron phosphate battery is at least 0.8V higher than that of lead-acid battery, if you want to change lithium iron phosphate battery, there should be no need to change any circuit. But it is best to add this kind of protective plate. According to my actual measurement, when the lead-acid battery is fully charged after landing, the measured voltage of the generator is generally about 14.1 V (Volkswagen car, RMS, peak voltage 19.9 V; other vehicles have not been measured). According to the information I have consulted, the overcharge protection voltage of the protection board is 14.6V (refers to 4 pieces, in fact, the protection mechanism is that no matter which charging voltage is higher than 3.65V, it will enter the protection).

Most of the water of the online battery is too deep. If you really want to replace the lithium iron phosphate battery, you must ask the brand and model of the battery. If the battery’s official website can be verified, the capacity can be basically guaranteed. It is not recommended that the kind of cell assembled with cylindrical cells such as 32650, the more cells, the more difficult it is to ensure consistency. Second, the capacity of this kind of cell is generally around 6Ah, and most of the connections are made with nickel spot welding. the resistivity of pure nickel is 5 times larger than that of pure copper. Even if the nickel chip between the cells is calculated according to 0.2X10mm, it is at most 2mm2. Per square millimeter carrying capacity is based on 10A/5, and the long-term load current is 4A. Even if the 60Ah capacity is 10 and 4 series, the continuous current is more than 40 A. If the oil fault is fired several times in a row, I doubt whether this kind of battery can hold up.

The low temperature resistance of lithium iron phosphate battery is not as good as that of lead acid battery, which is similar to the low temperature environment of minus 20 or 30 degrees outside in the northeast, so we should not use lithium iron phosphate.

To the very car owner’s advice, do not choose too large capacity, directly buy 40Ah is enough; the original car 40Ah but low voltage, battery effective capacity utilization is certainly lower than lithium iron phosphate. And a battery of this size, with an A123 cell, can only do 40Ah (unless A123 has a new suitable cell). If you assemble it yourself, there is no need to use a cell with such a high charge and discharge rate as A123, because a maximum of 150A is enough, try to choose those large units, not cylindrical ones (space utilization problem, wiring complexity) but there are not many cells that want to find the right size.

VIII. Appendix

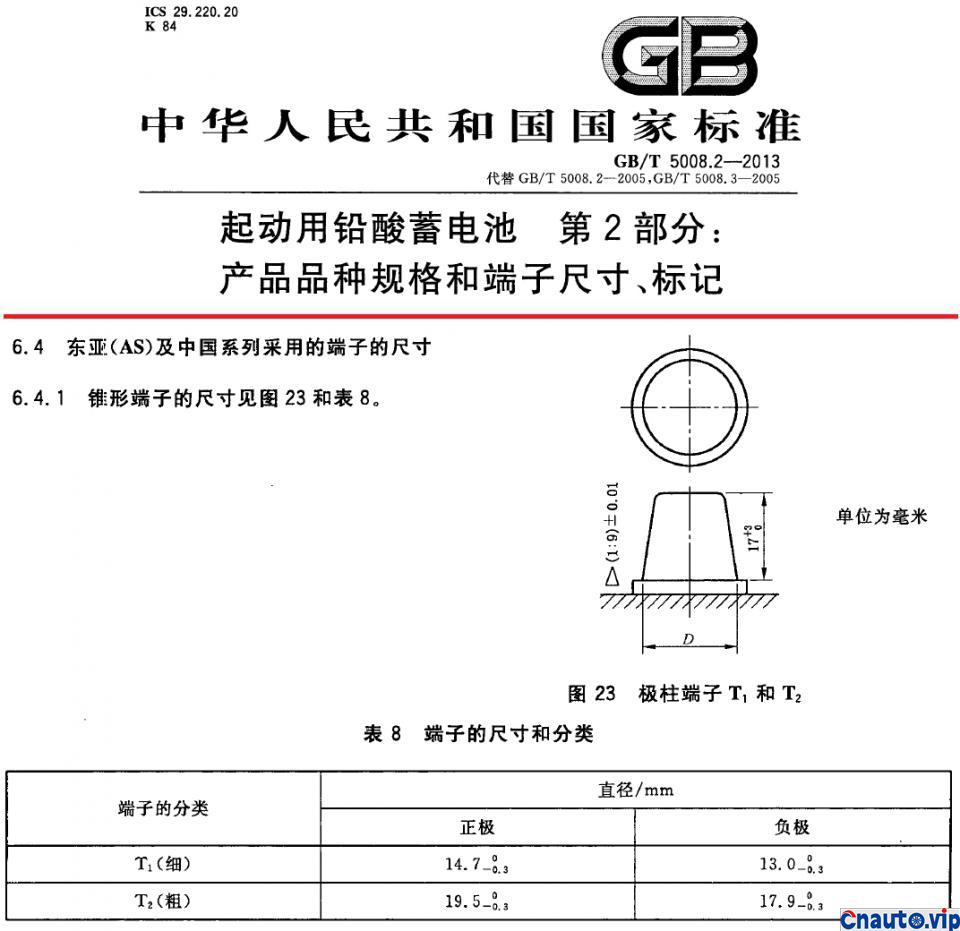

1. The pole of the GB battery:

There are two sizes of battery terminals in the national standard.

If it is made of brass, it is recommended that the manufacturer make a cylinder directly.

T1 (thin) positive 13.7 negative 12.0

T2 (coarse) positive 18.5 negative 16.9.

Or change the taper to 1:20.

2. A123 cell official website: * / automotive/products/cells/

3. Introduction of A123 12V startup battery: * / automotive/products/systems/12v-starter-battery/

4. If you assemble it yourself, the battery case suitable for very small Business:

If you use it very wisely, you must choose inverse L or 38B19-L.

The above content is simultaneously posted in Auto Home.

Feedback on long-term use

9.1 to 2023.2.27, three years ago. No problem.

April 1, 2024

April 1, 2024