Fault repair for the front chassis cover lock of the 2006 old classic Focus sedan MT

I was at home during the holiday on May 2. I wanted to open Xiaofu’s cabin cover and look at the oil dipstick. In the end, I used a key to open it. Unfortunately, the key was idling, but it couldn’t be opened. It was found that the claw at the end of the lock was broken and the plastic parts were aging. I finally opened the cover by making my own tools.

The claw on this side is also broken.

The claws on both ends were f * cking broken. It’s just that the connecting rod is still good.

Remove it all and take it home.

I checked several accessories stores on a certain treasure store, but no one paid attention to you. I think it’s over for the holidays. There was no choice. I had to rush to use the car the next day. When you get angry, deal with it yourself!

Digging through an aluminum alloy plate at home. Mark and punch. The aperture is 10 mm.

Digging through an aluminum alloy plate at home. Mark and punch. The aperture is 10 mm.

Saw open with a hand saw.

Two aluminum claws. Put on vise and process the file.

Remove the broken clip at the end of the lock head and make two holes. The distance between the holes is determined according to the situation. The diameter is 3mm and the depth is about 6 to 8 mm.

Anchoring teeth are machined at the root of the aluminum alloy claw, which can be inserted into two holes made at the end of the lock cylinder.

The processed aluminum alloy clip and the other end of the connecting rod of the lock are also processed in the same way.

Use good glue to glue the aluminum alloy clip and the lock head firmly.

The end of the lock is also used to glue the aluminum alloy clip and the lock firmly.

After making, go to the car and install it. The opening of the aluminum alloy claw should be slowly trimmed with a file until the groove of the plastic ball fits in slightly tighter so that it will not fall off.

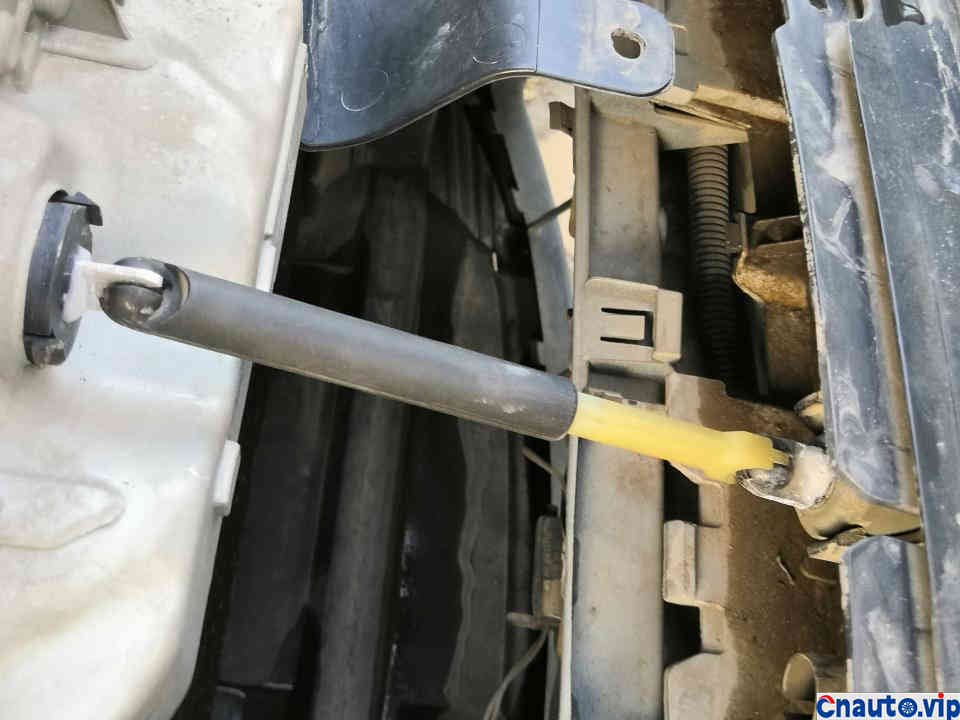

Picture of the lock side after installation.

Effect of installation on the entire sides of the connecting rod. Done! The aluminum alloy claws will never break again until the connecting rod ages and breaks. Wait until a few days and buy a connecting pole to replace it. Forever trouble.

I hope this post will be helpful to Fuyou who have hands-on skills.

Hot Information

Tesla Autopilot and similar automated driving systems get ‘poor’ rating from prominent safety group

April 1, 2024

April 1, 2024 Localization of EV parts without production scalability may not help cut EV price, says President, Amara Raja

March 27, 2024

March 27, 2024

JCTSL may turn bus stands into charging points for e-buses

March 27, 2024

March 27, 2024 You May Like