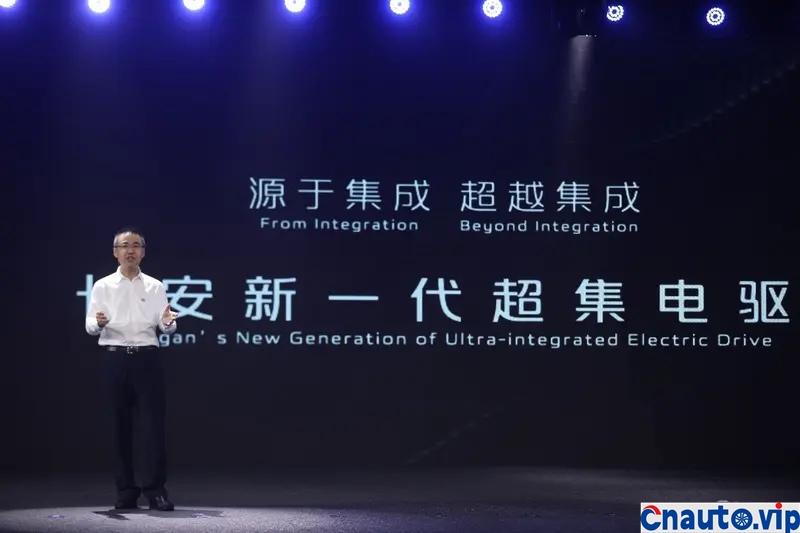

Is electric drives also involved? The advanced path to all-in-one integration

I am not only an electronic enthusiast, but also an old car owner in Changan. These two days often see in the group of car friends to discuss: what benefits can the new generation of supercollector drive bring to us in Chang’an? In this regard, I thought for a long time, found that one or two words are not clear at all, and finally decided to talk about their views through the platform of the forum.

Electric drive can be said to be the heart of a pure tram, which affects acceleration, slope climbing, range, etc., and plays a very important role in the tram. As a result, electric drive has also become a “must-compete” for major car companies, both old traditional car companies and new car-building forces are beginning to study how to make electric drive more powerful.

As early as 2018, there were more than 200 electric drive manufacturers in the announcement of new energy vehicles in China. At present, some products have been exported, represented by independent motor suppliers such as Shanghai Electric Drive, Jingjin Electric, Shanghai Daxun and so on. In addition, BYD, BAIC New Energy, Changan, Weilai and other vehicle enterprises are also carrying out electrical system research and development. Moreover, electric drive has experienced several technical iterations from single to integrated, from all-in-one to multi-integration. In terms of shape, the development and evolution of electric drive is like the evolution of mobile phones, from the original corded phones, to mobile phones, functional phones, to now smart phones, the size is getting smaller and smaller, more and more functions.

From the perspective of development, integrated design is indeed the trend of the times, and the experience it can bring to car owners is certainly better. The early development of electric drive system is limited by technology, each electronic device is separate, large size, heavy weight, and not efficient enough. Therefore, in recent years, the major automobile companies have focused on the integrated research and development of electric drive.

Take Chang’an as an example, the three-in-one electric drive before Chang’an integrates electric control, motor and reducer into one. Compared with the early electric drive scheme, the three-in-one electric drive system has compact structure, smaller volume and lighter weight, which can effectively reduce driving energy consumption.

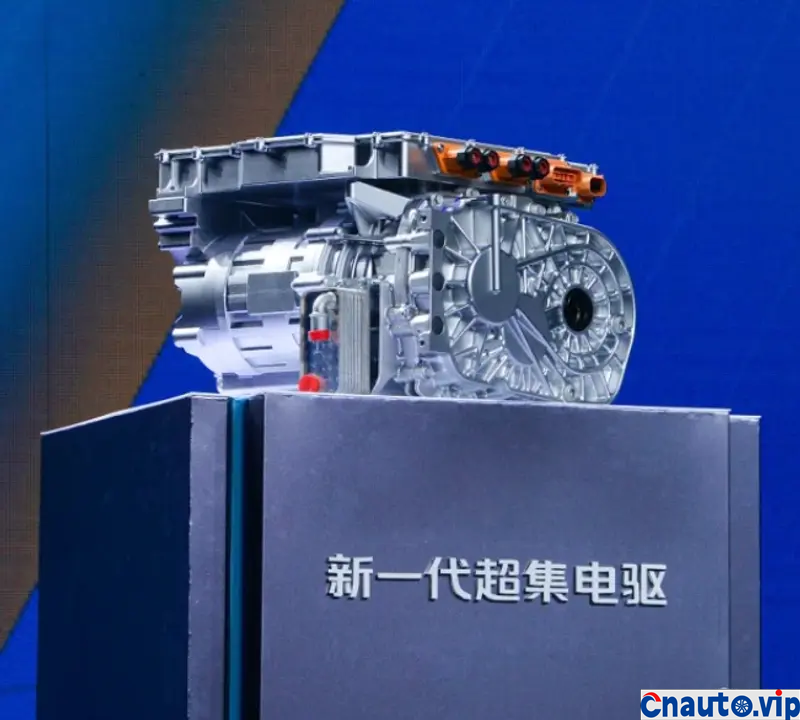

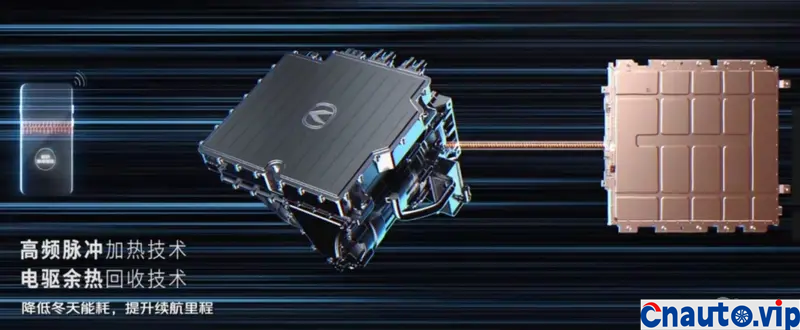

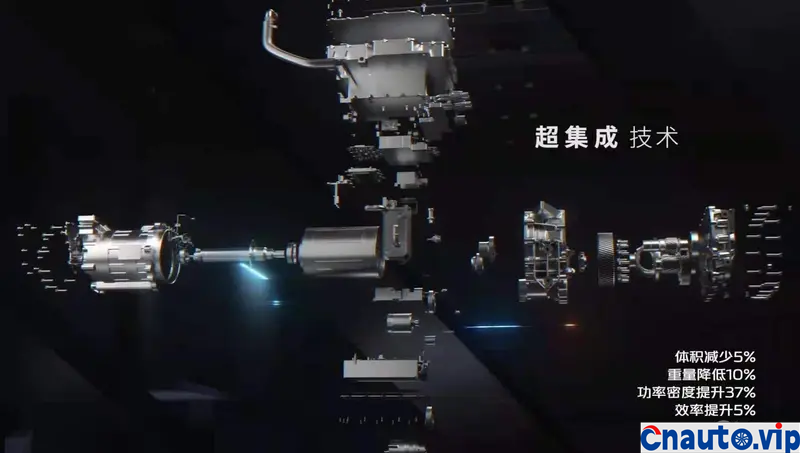

The newly released Changan new generation supercollector drive integrates multi-functions such as motor, reducer, motor controller, DCDC, DCAC, DC boost, high voltage shunt, AC charging and so on.

To put it simply, there are more integrated parts, which are smaller in size and weight than a three-in-one electric drive, so lightening the body can also reduce energy consumption to a certain extent, thus improving battery life. I have read a report that every time a new energy vehicle reduces its 100Kg weight, its mileage can be increased by 10%, 11%, 20%, and 20%, respectively.

Seeing this, many motorists may think that compared with three-in-one electric drive, supercollector drive is nothing more than reducing power consumption and improving battery life, then you are very wrong! Chang’an is particularly concerned about the low temperature in winter and the serious discount of mileage in the northern region. It is often seen that riders joke that “in the northeast, electric cars become electric dads in winter.” some mileage will even be cut in half, and many car owners do not even dare to warm up in winter, seriously affecting the use experience.

This is due to the decline in battery activity in extremely low temperatures in winter. Take the lithium iron phosphate battery with 50 kilowatt-hour electricity as an example, in the environment of minus 20 degrees in the north, the amount of electricity that can be used is reduced to only about 35 kilowatt-hour electricity, with an attenuation of more than 30%. Of course, I’m just taking lithium iron phosphate batteries as an example. No tram battery can escape the curse of endurance decay in winter.

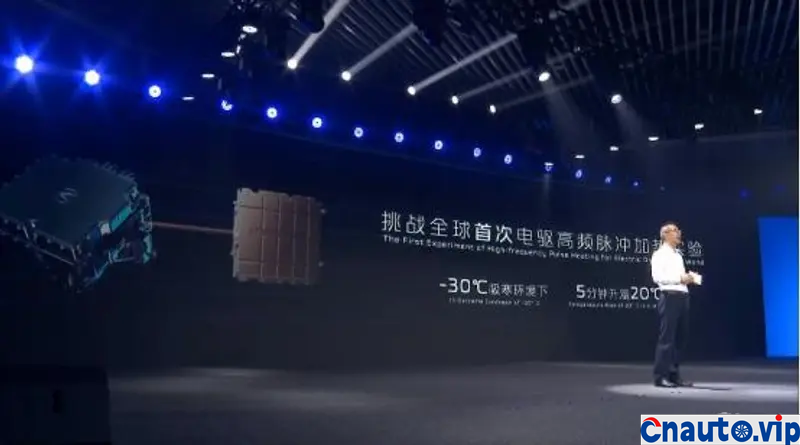

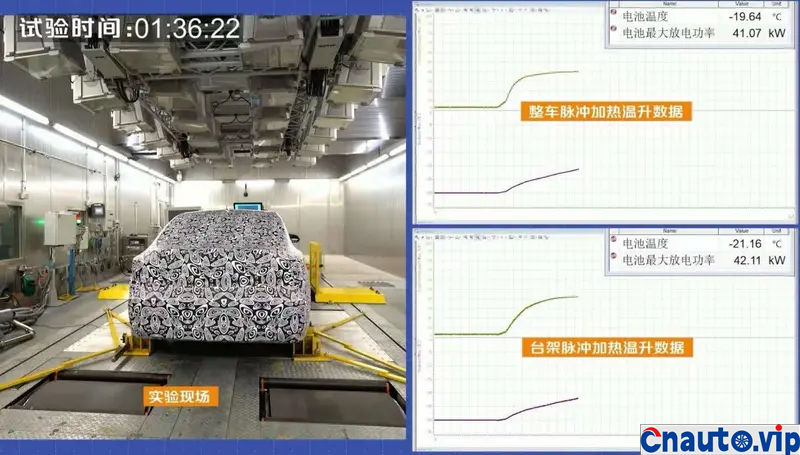

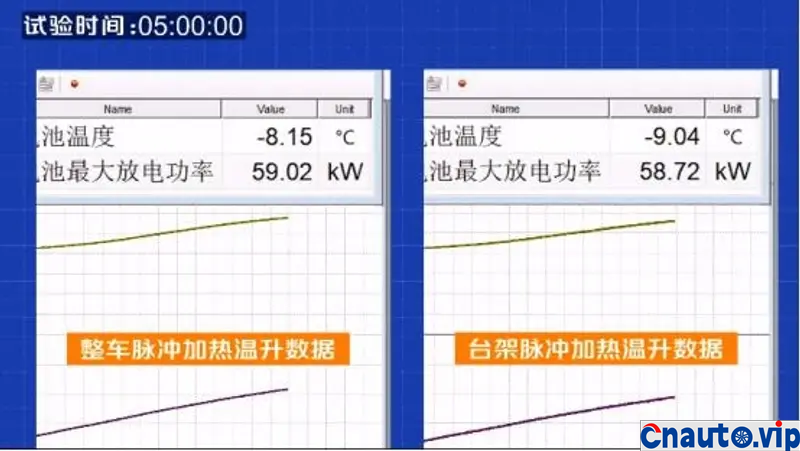

In order to solve this problem, the new generation of supercollector drive in Chang’an has realized the extremely fast heating of lithium battery at ultra-low temperature. The battery can be heated from-30 °C to more than-10 °C in 5 minutes, effectively improving the battery activity and increasing the winter mileage by up to 40-70km. For car owners in the north, they do not turn on electricity to go out the door, or even dare not warm the wind.

In addition to what has been said above, I think the new generation of supercollector drive in Chang’an has another advantage, but it needs our detailed products. Changan new generation supercollector drive develops two series products of 450V and 800V, which can meet the power demand of 160V-300kW. In other words, the new generation of supercollector drive in Changan can be carried on the same model. However, Chang’an uses super materials, and different models only need batteries, thus reducing research and production investment. I dare to guess: the cost of our car should also be reduced accordingly.

To sum up, I think the benefits that Changan supercollector electric drive can bring to us are that cyclists in Northeast China no longer have to worry about shrinking service life in winter; at the same time, energy consumption will also be reduced, so we should be able to save more money on electricity; another is that we may be able to buy better cars with less money. It is said that the new generation of power collection in Chang’an will be built on the code name C385, and I would like to experience it right away.

Recommended Suppliers

April 1, 2024

April 1, 2024  March 27, 2024

March 27, 2024

March 27, 2024

March 27, 2024