Big Bear comes to replace the gearbox bracket

1. Bear 5W km later, driving at a low speed in the urban area, the gearbox gradually felt more and more obvious frustration in the downshift of 3-2-1, accompanied by an obvious click, click sound. A while ago, many car owners at the Morduko Knight Club said that it could significantly improve the situation after changing the brackets of the gearbox, so I also joined the fun to try a high-equipped hydraulic version.

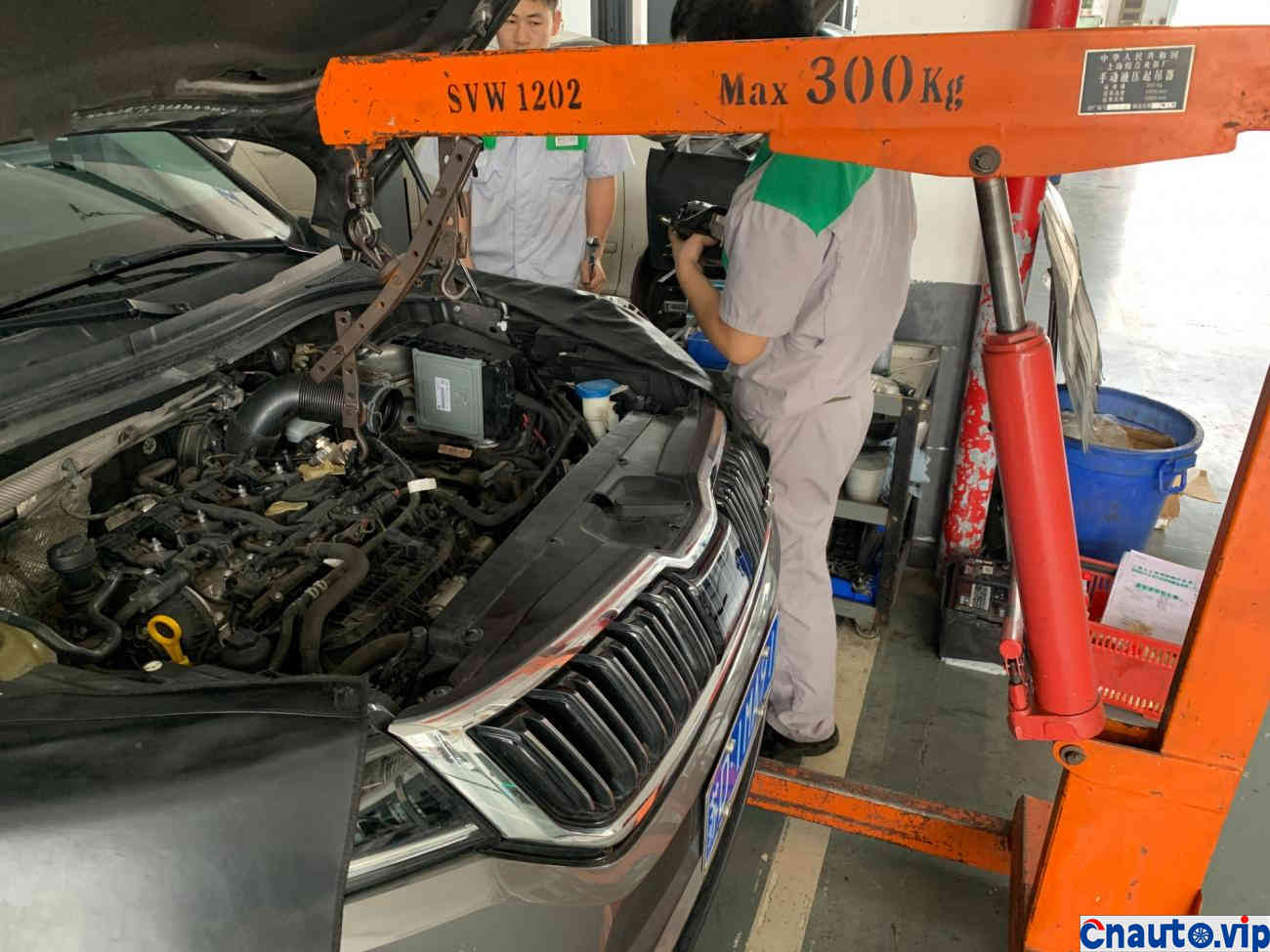

two。 After the arrival of the hydraulic support, consulted the technical director of the 4S store, said that the replacement is not troublesome, as long as 1-2 hours. Find a business trip at the end of the afternoon time is still rich, contact into the 4S store to do it.

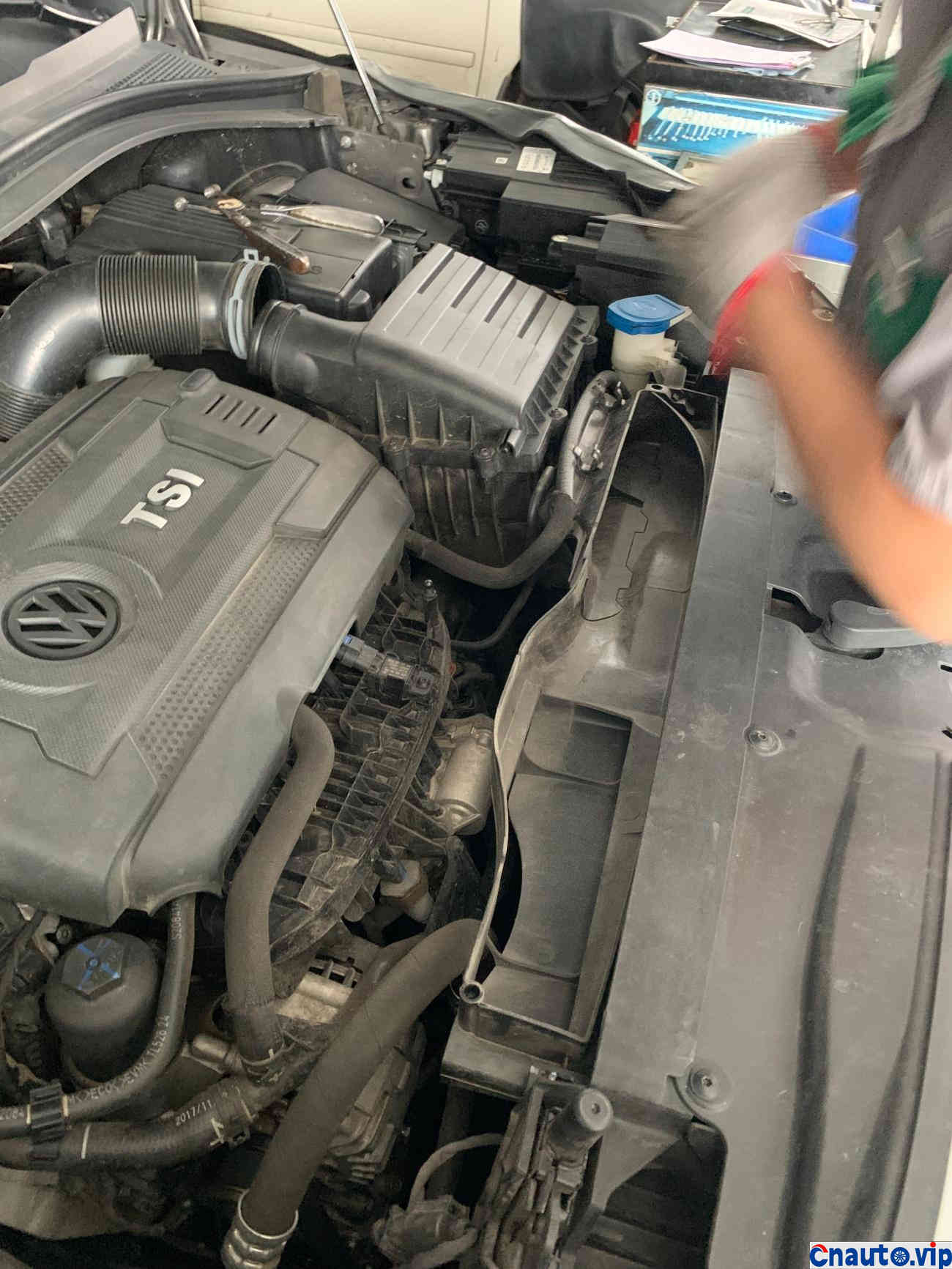

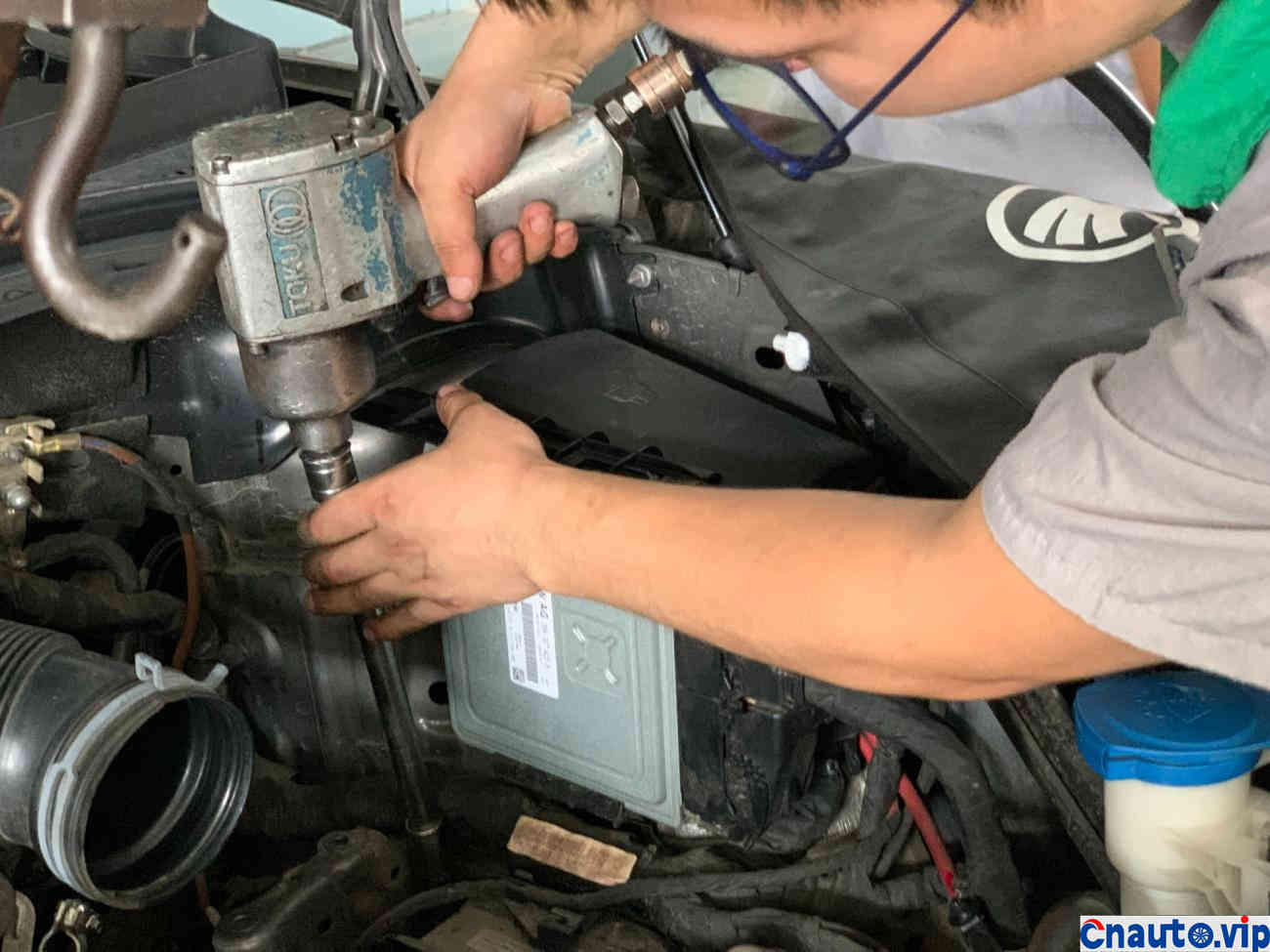

3. Changing the gearbox bracket requires the removal of batteries and battery bases, and the masters in 4S stores are experienced professionals, because the daily work is a model under the maintenance Kodak brand and has been specially trained. The tool is also a general / special tool for Volkswagen-Skoda unified configuration, so the speed of disassembly and disassembly is super fast.

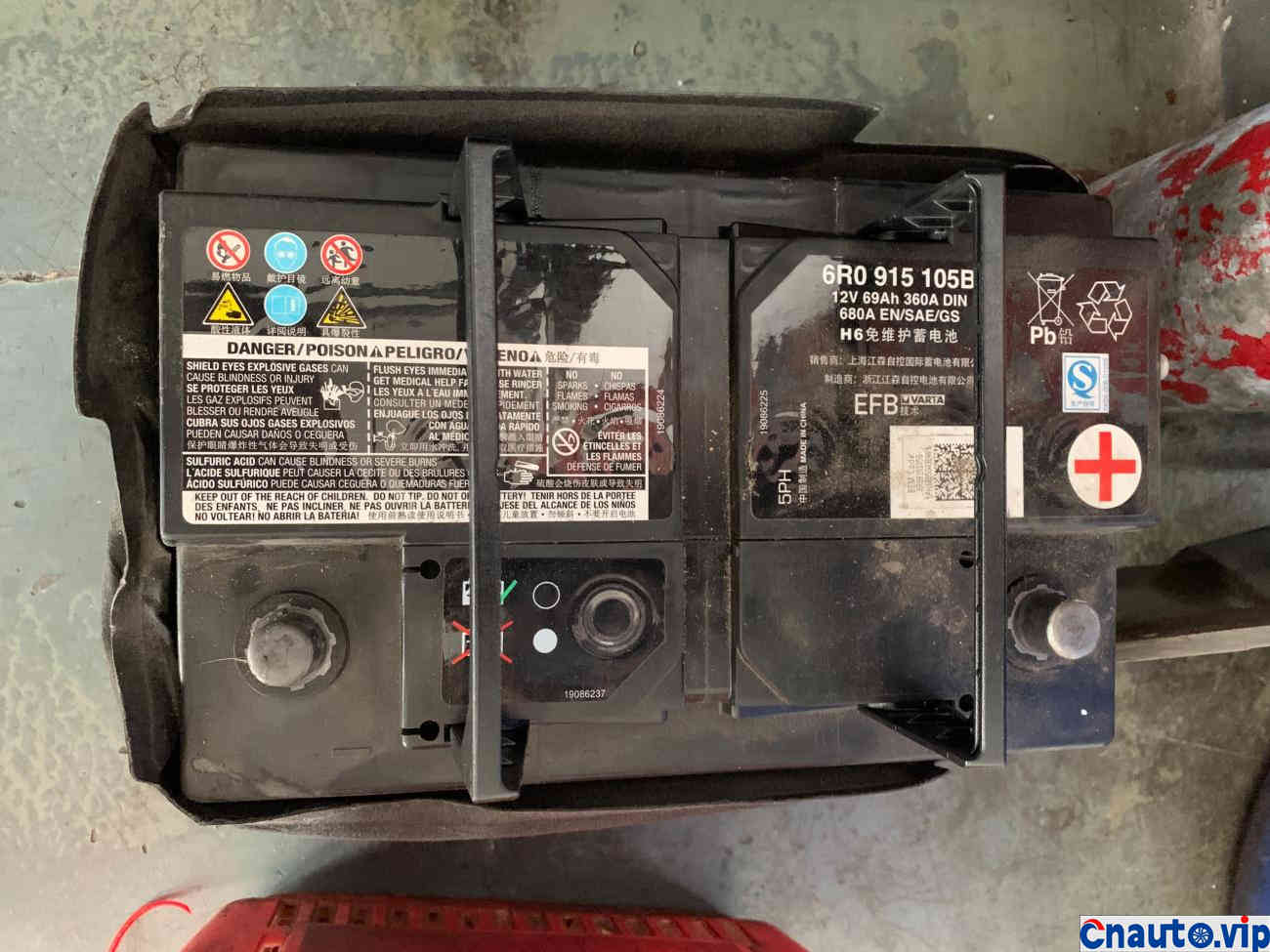

4. In the blink of an eye, the young master removed the air intake air filter box and the battery, which is a Varta brand made by Johnson controls, and it is a special contribution to EFB technology 69Ah, which can not be bought on the outside market.

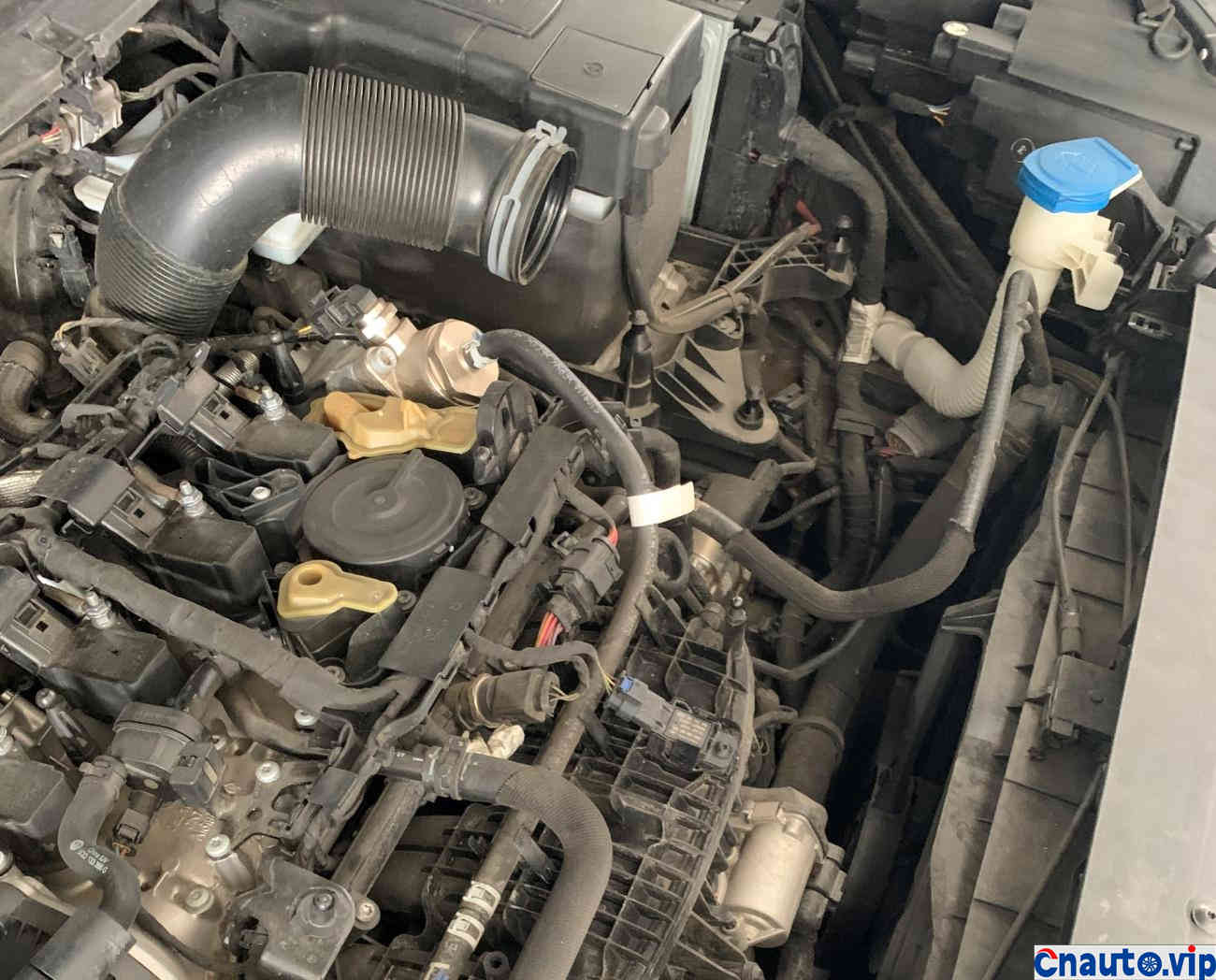

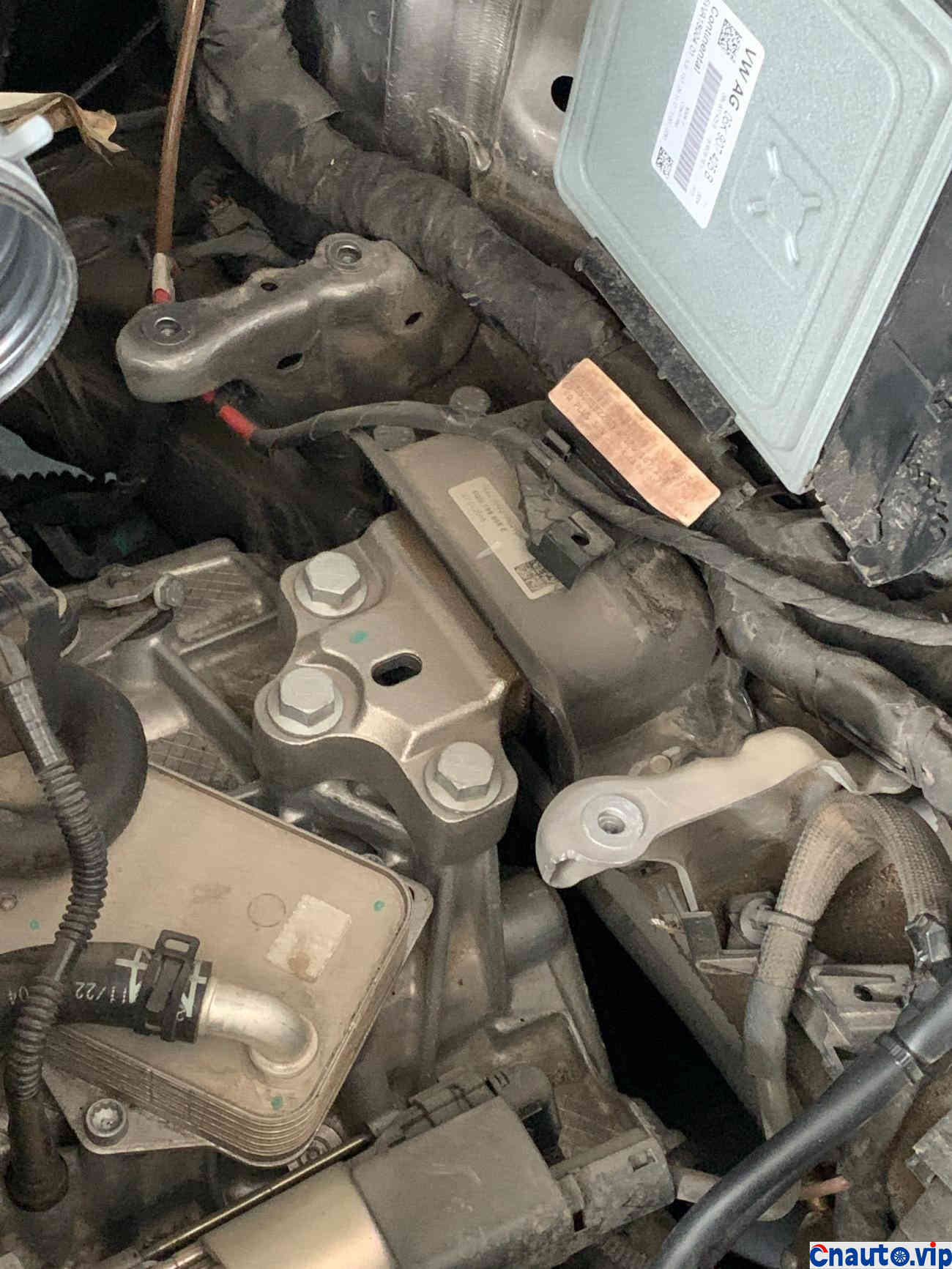

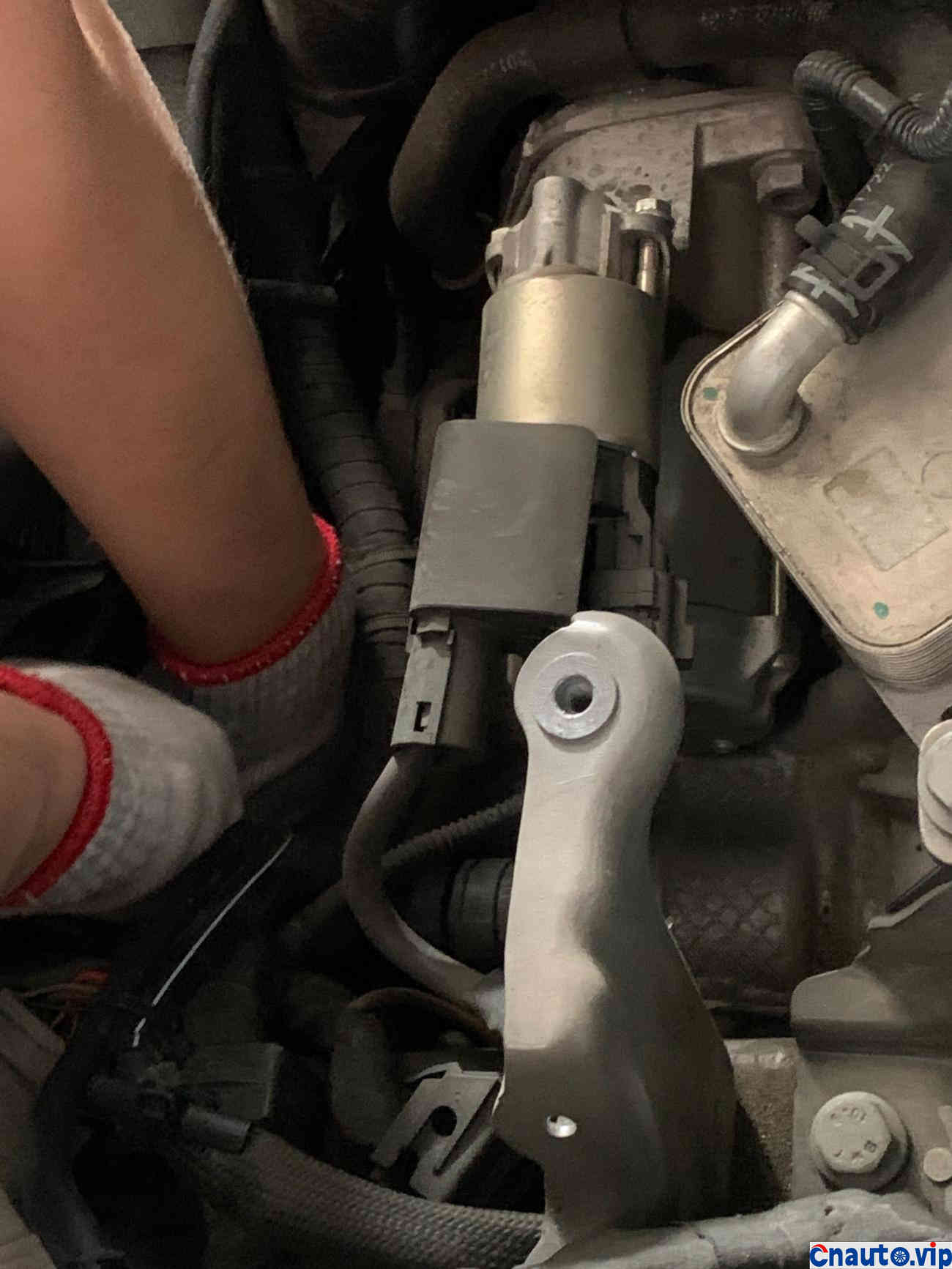

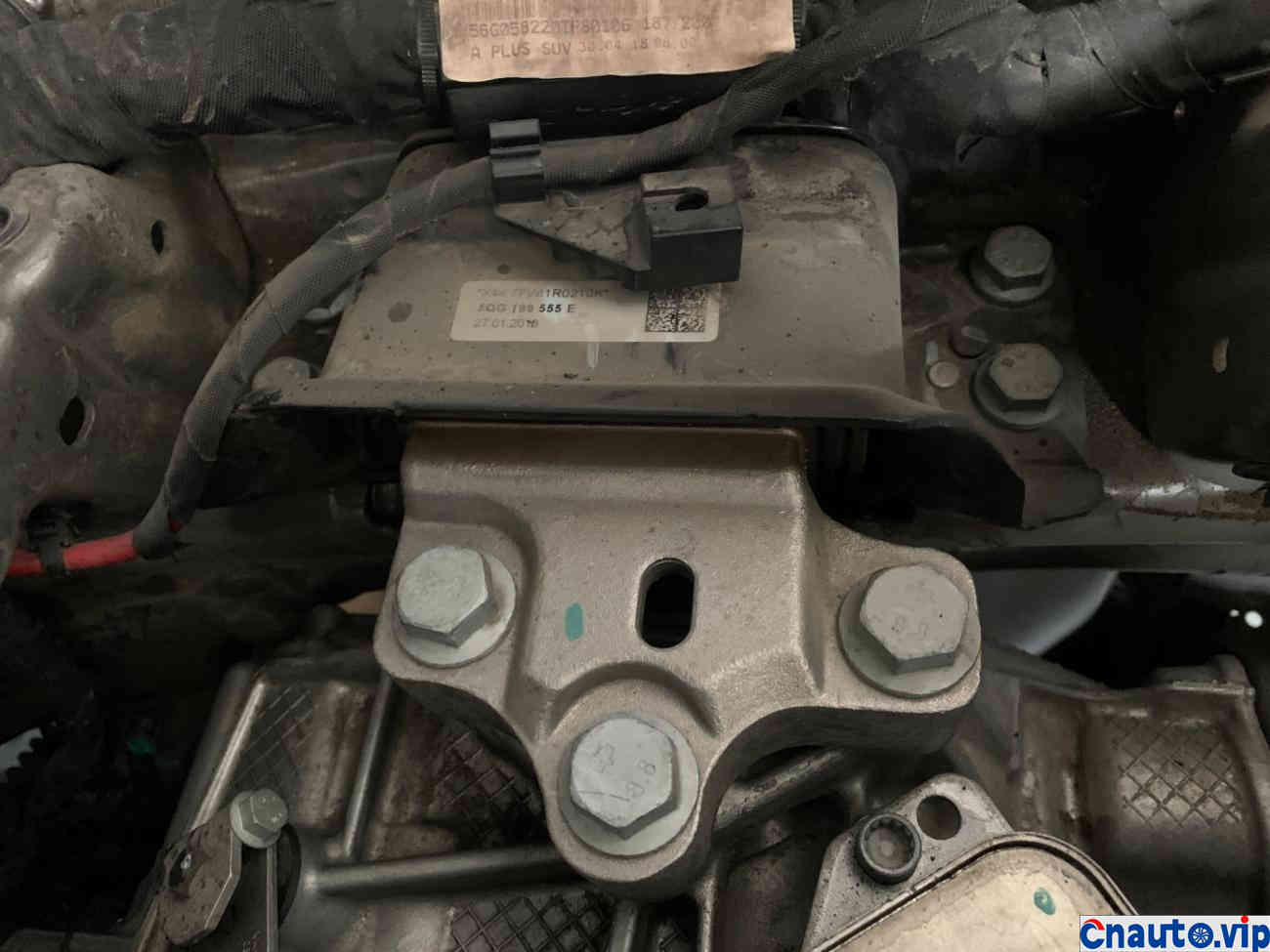

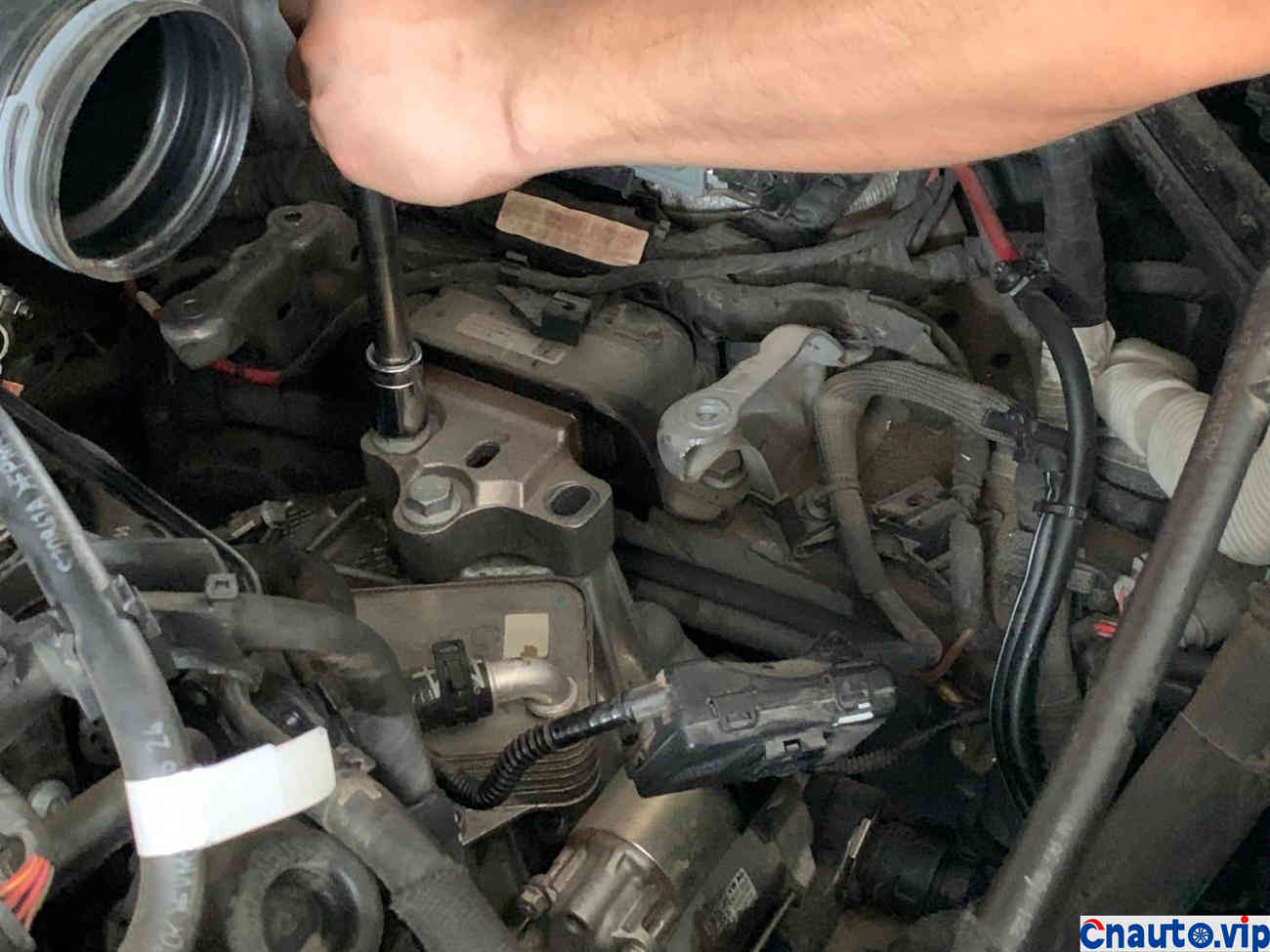

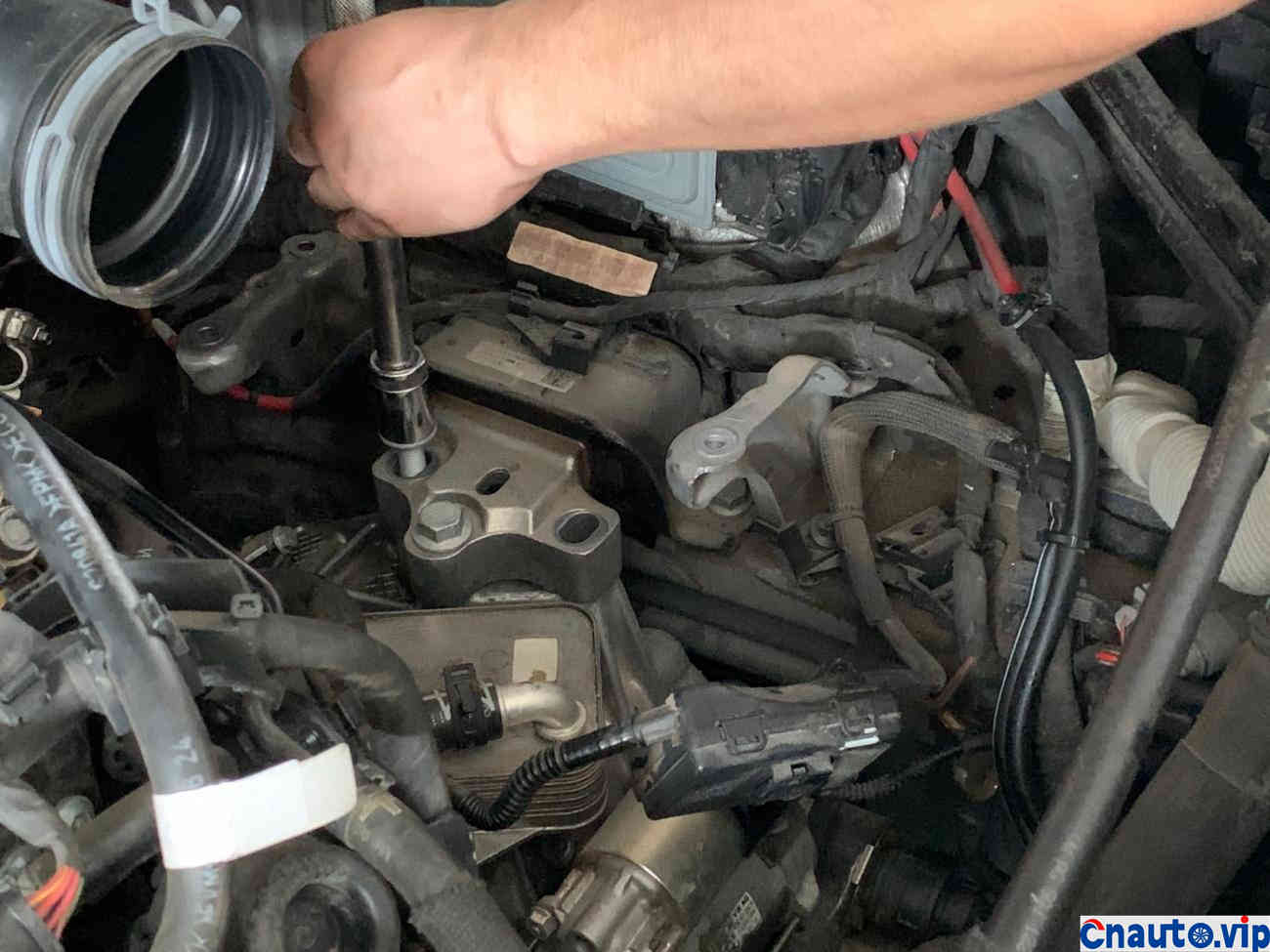

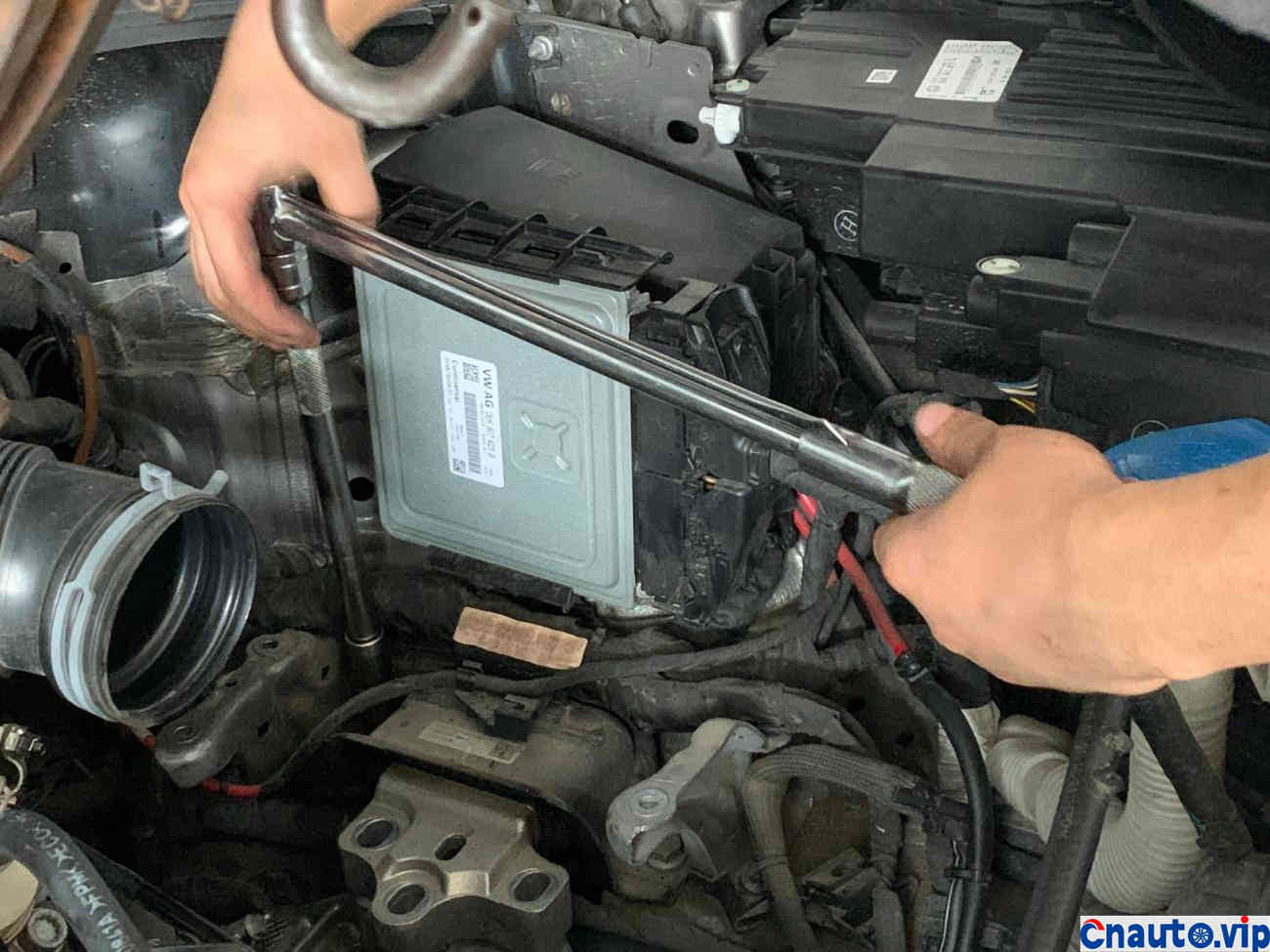

5. After the battery base is removed, you can see the gearbox bracket, which is a combination of silver aluminum alloy die casting and rubber. The rubber part of the original factory is 100% rubber. After using it for a period of time, the rubber body is deformed, and it is not easy to reset to the standard state required by the design after fatigue, so it is not enough to deal with the huge torque up and down before and after dealing with the gearbox with low speed and high torque such as Volkswagen DQ500.

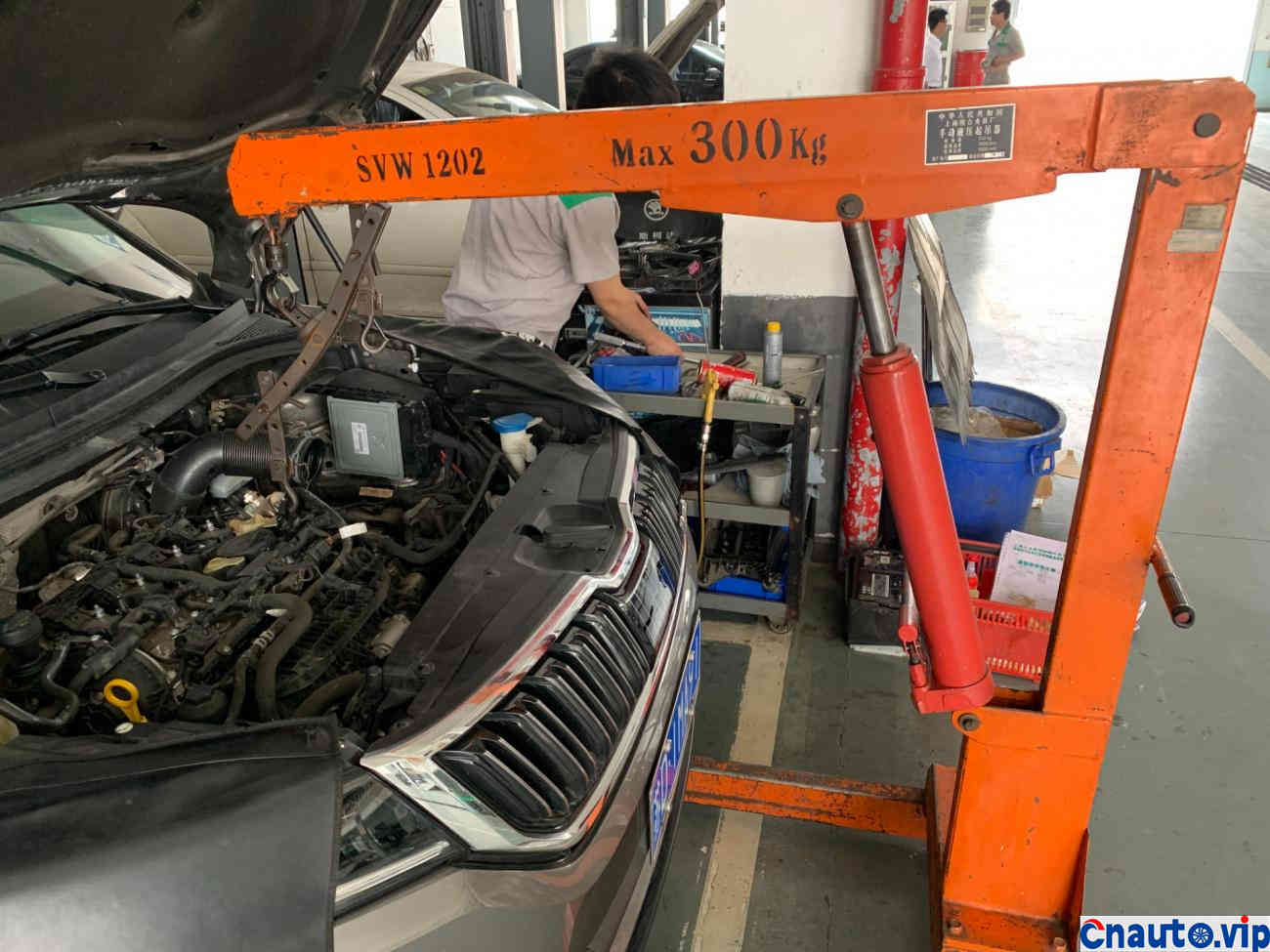

6. Before disassembling the gearbox bracket, use the engine disassembly special manual hydraulic hanger to lift the engine and gearbox, as well as the front suspension securely, and raise it a little bit.

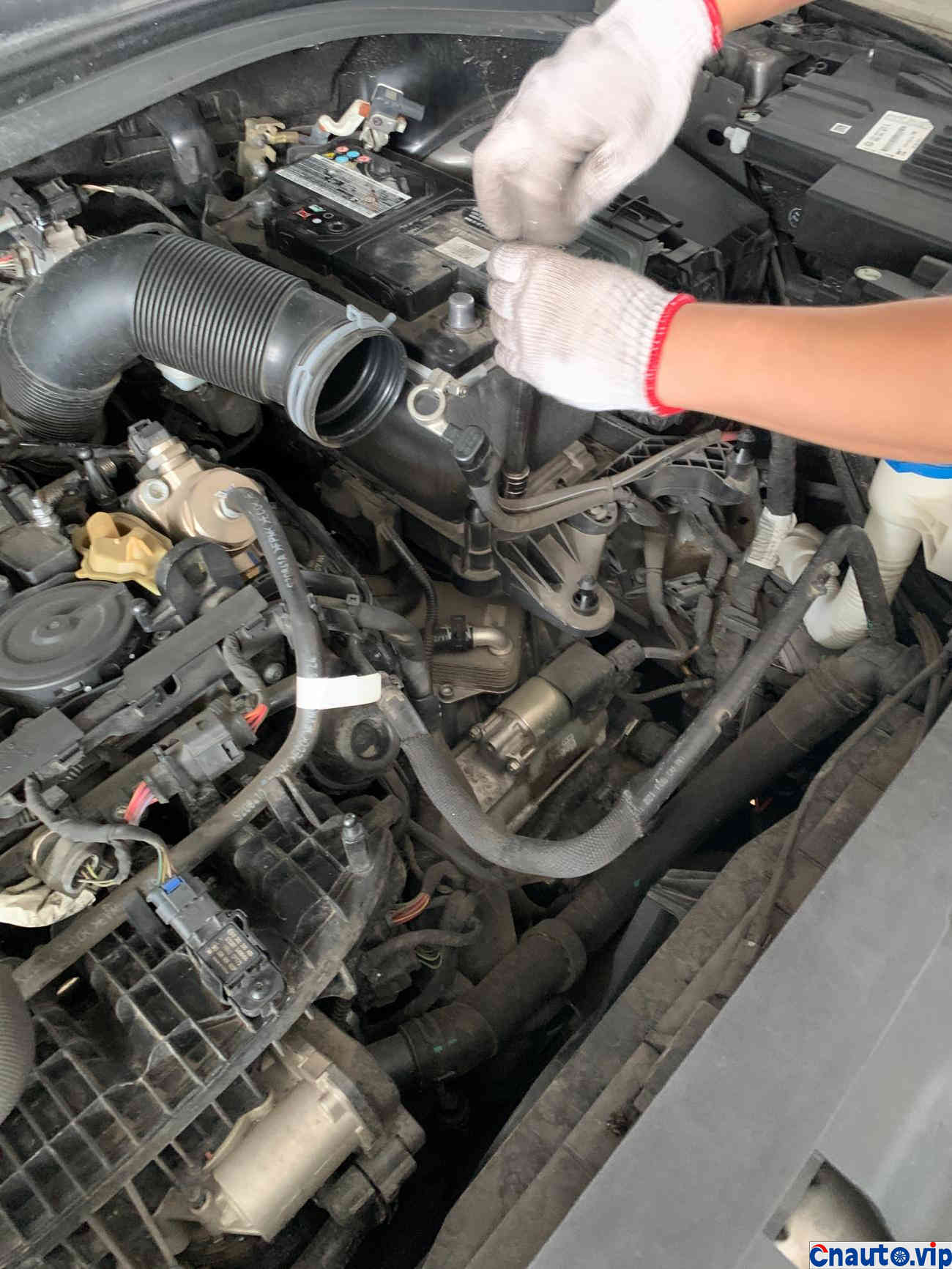

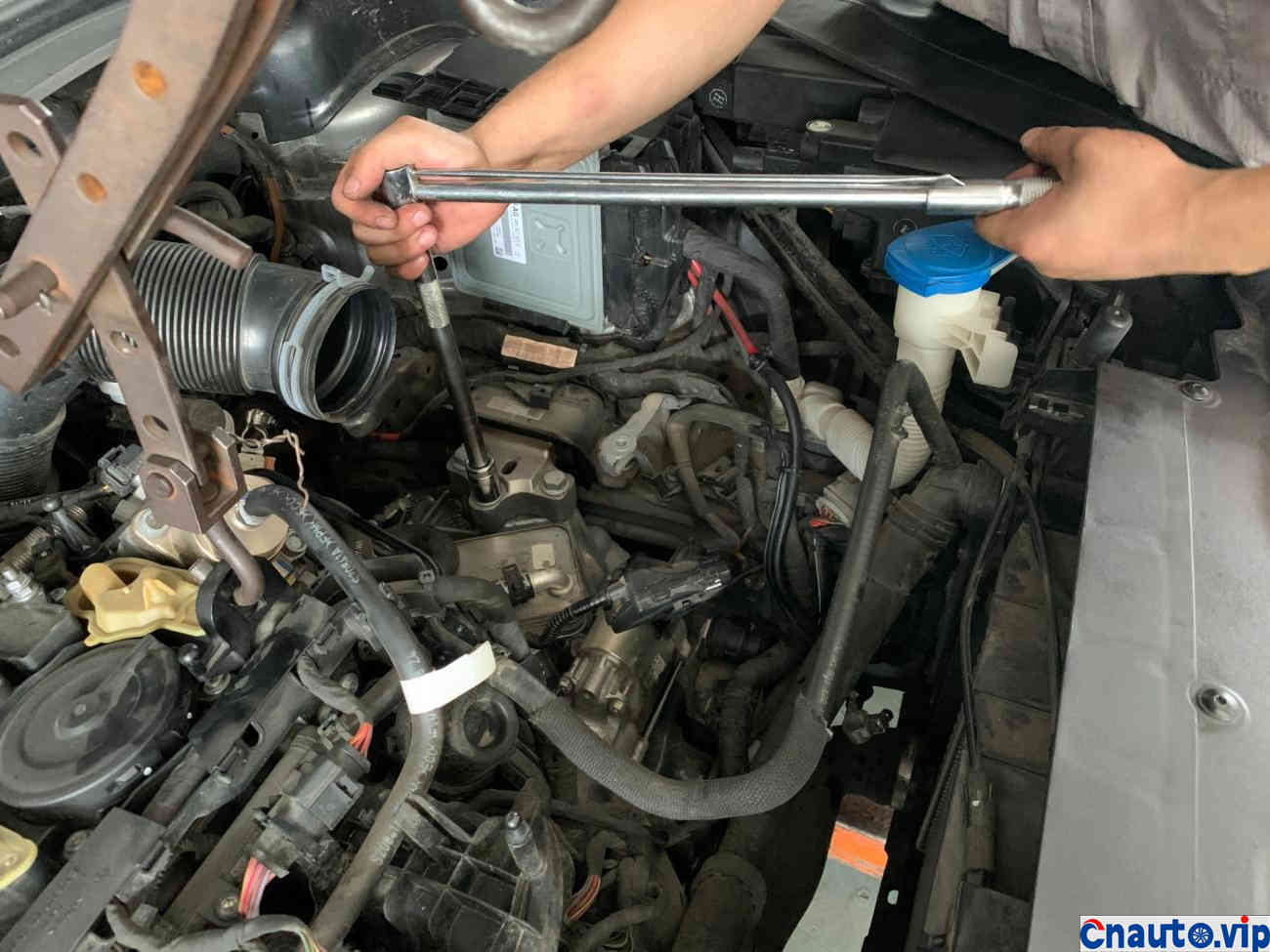

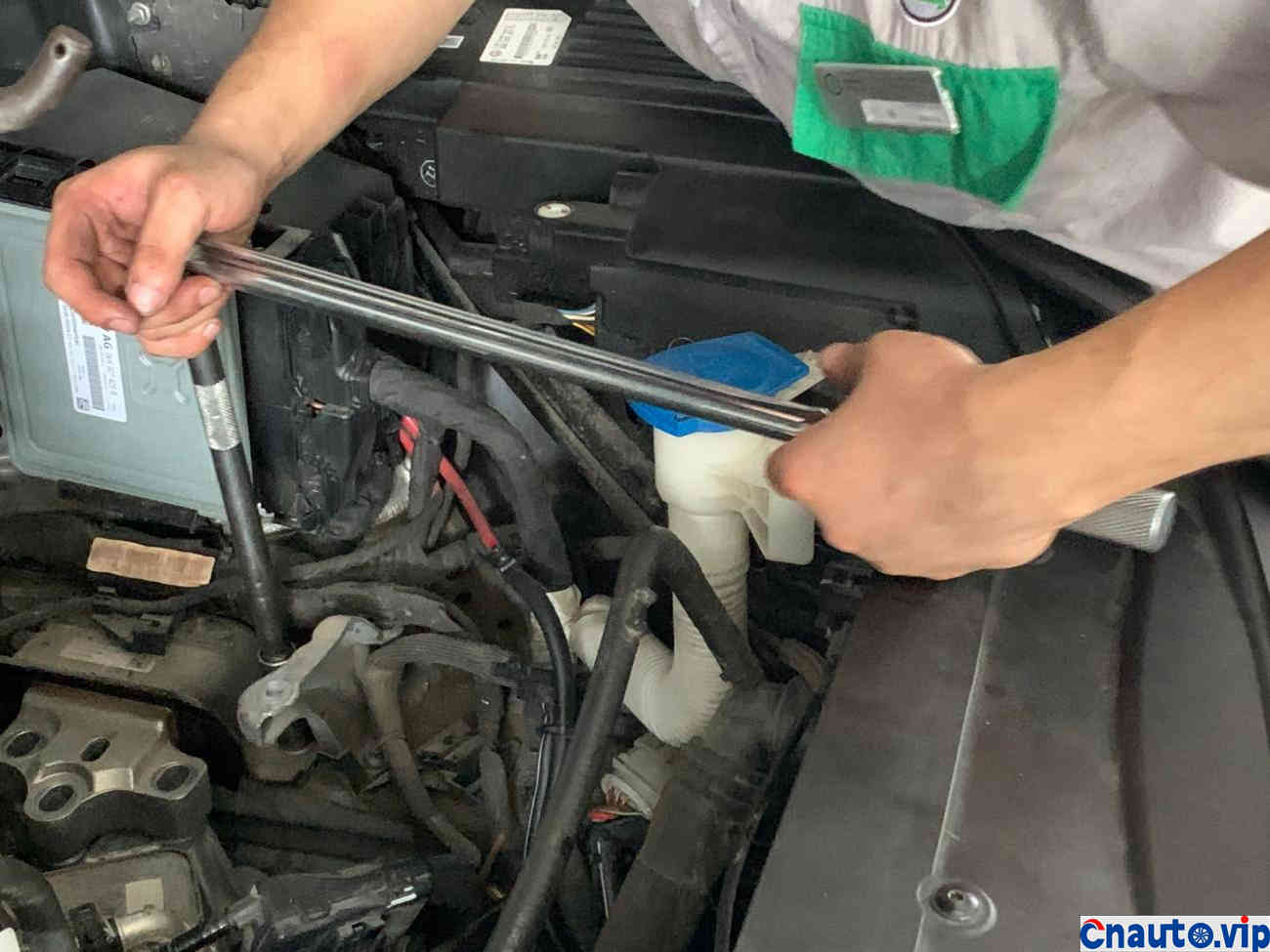

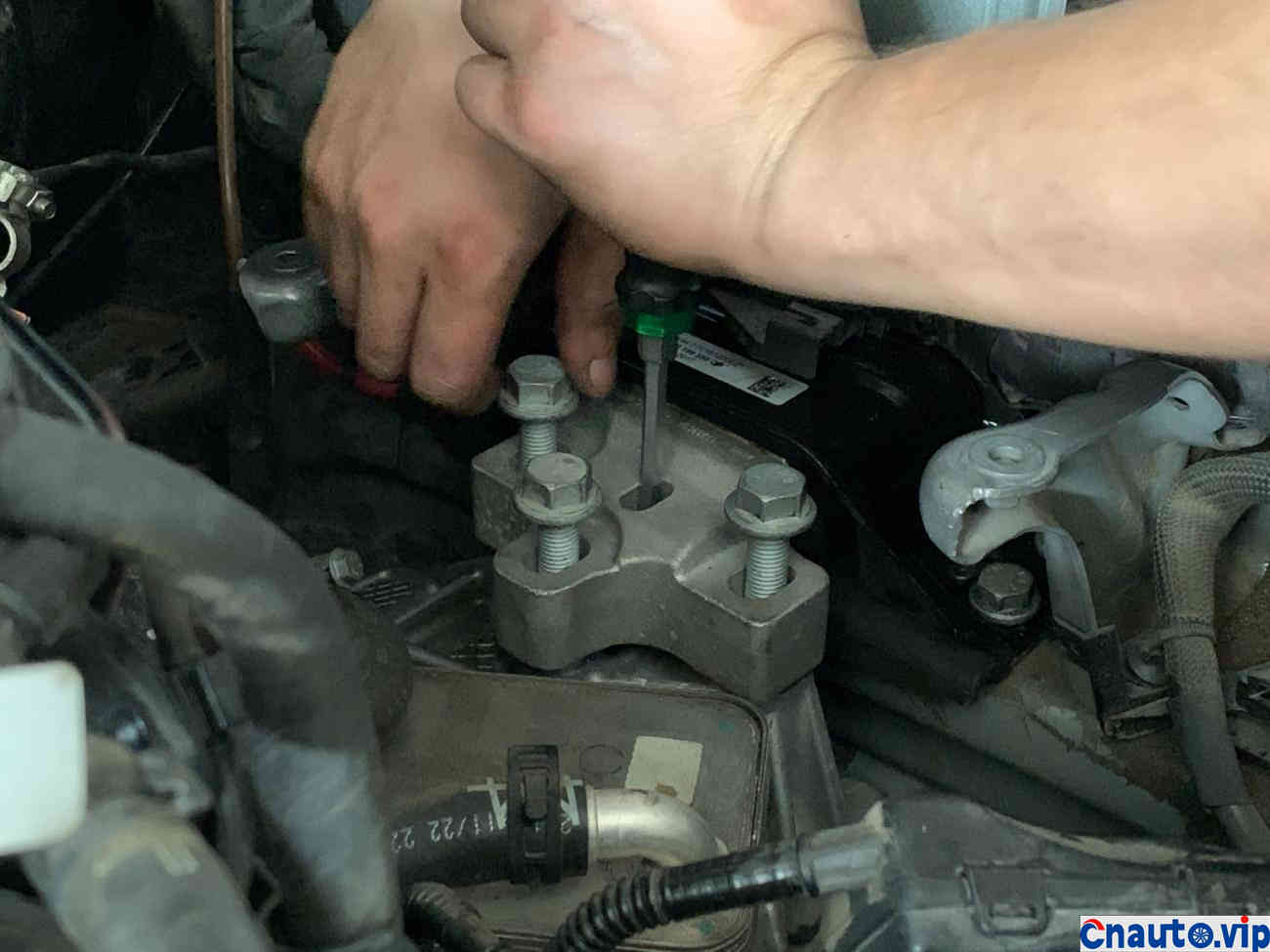

7. Then slowly release the three large bolts linked to the bracket and the gearbox, and then manually raise the hydraulic hanger slightly to maintain the height of the engine and gearbox after falling slightly to the normal position. After the three bolts are removed, remove the four fixed frame bolts on the rubber side.

8. This is the case with the all-rubber bracket of the original car. Holding the cushion pad in the middle of the rubber parts with your hand can shake up / back / left and right, and it is very loose. Compared with the new bracket to be replaced, it can be found that the buffer in the middle of the rubber shock absorber part of the new bracket is different, which contains a hydraulic part (it is said that this is the standard match between the European MQB platform EA888 and the gearbox), which is domestic export to domestic sales? I don’t know, whether it’s Tuang or Tuguan, as long as it works, ha!

9. The master quickly replaced the new bracket step by step, set the original torque value with the special advanced torque wrench configured by Volkswagen-Skoda, tightened the bolts one by one, installed the battery and air intake front-end assembly, and tried it on the road.

10. Road test results: at medium and low speed deceleration, the obvious click and click sound of the gearbox in front of the 3-2-1 gear becomes so small that it can not be heard without paying attention. Occasionally if the brake is more urgent when the 2-1 gear stops, there will be a slight click, do not pay special attention to no feeling at all, basically the same as the new car. The overall noise and sudden frustration of the gearbox decreased, indicating that the new part works very well, the value of this honeysuckle.

Hot Information

Tesla Autopilot and similar automated driving systems get ‘poor’ rating from prominent safety group

April 1, 2024

April 1, 2024 Localization of EV parts without production scalability may not help cut EV price, says President, Amara Raja

March 27, 2024

March 27, 2024

JCTSL may turn bus stands into charging points for e-buses

March 27, 2024

March 27, 2024 You May Like