Car friends a Touareg 3.0T 150000 km oil burning problem about 2000 km burning a liter of oil, engine code EA837 mechanical supercharger, eight-gear manual self-integrated transmission, Volkswagen’s unique four-wheel drive system, matching air suspension. Such a good configuration still can not avoid the problem of burning engine oil. Today, we will begin to repair it to restore its original power and make him say goodbye to burning engine oil. When we took apart the machine, we found that the gas string of the piston was very serious, and everything else was fine, just replace the parts normally. There is no abnormal driving for 2000 kilometers after maintenance. As there are many small jobs in vehicle maintenance and can not concentrate, I have to work overtime to repair the engine at night.

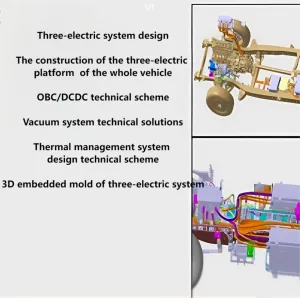

![]()

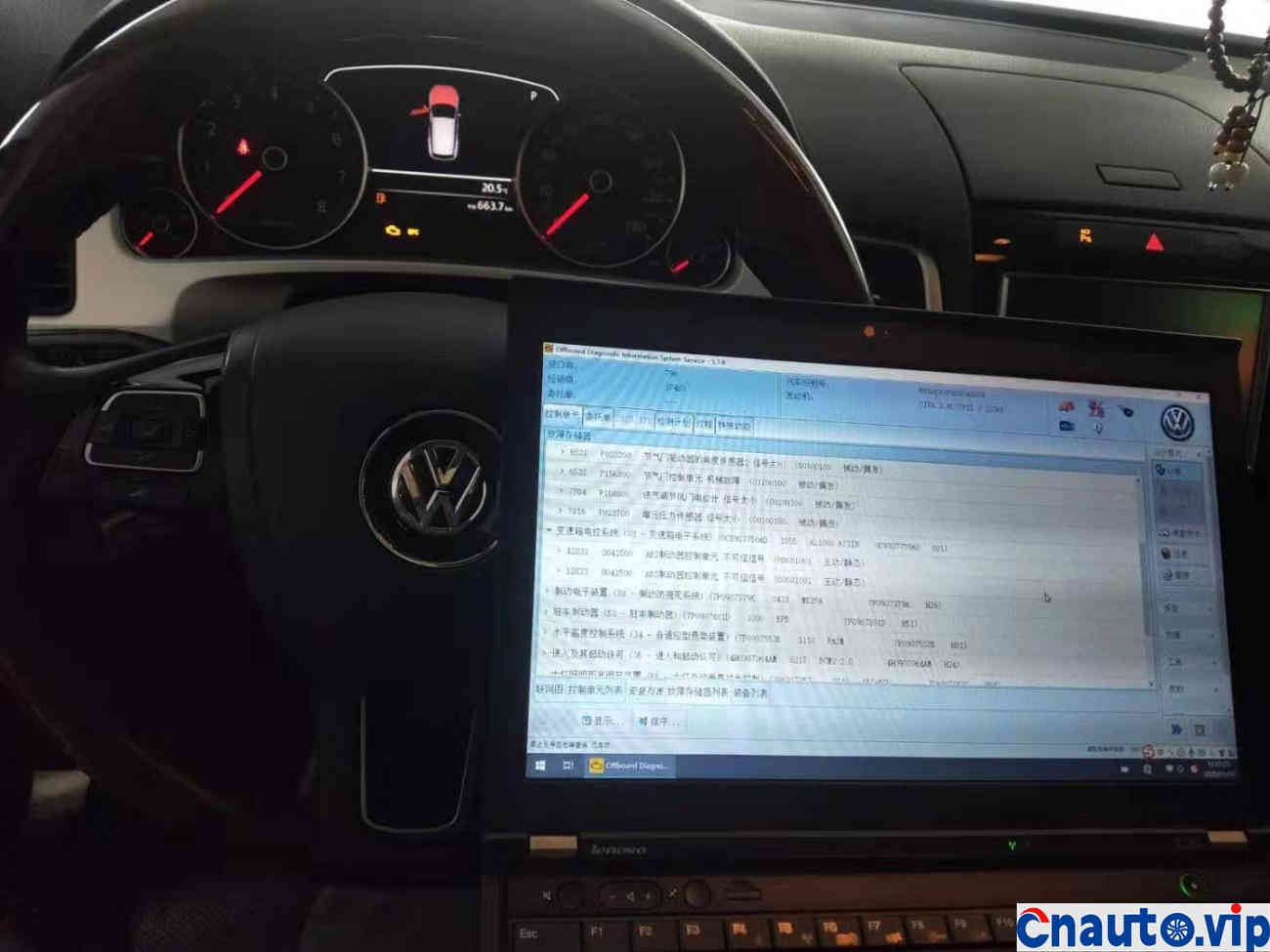

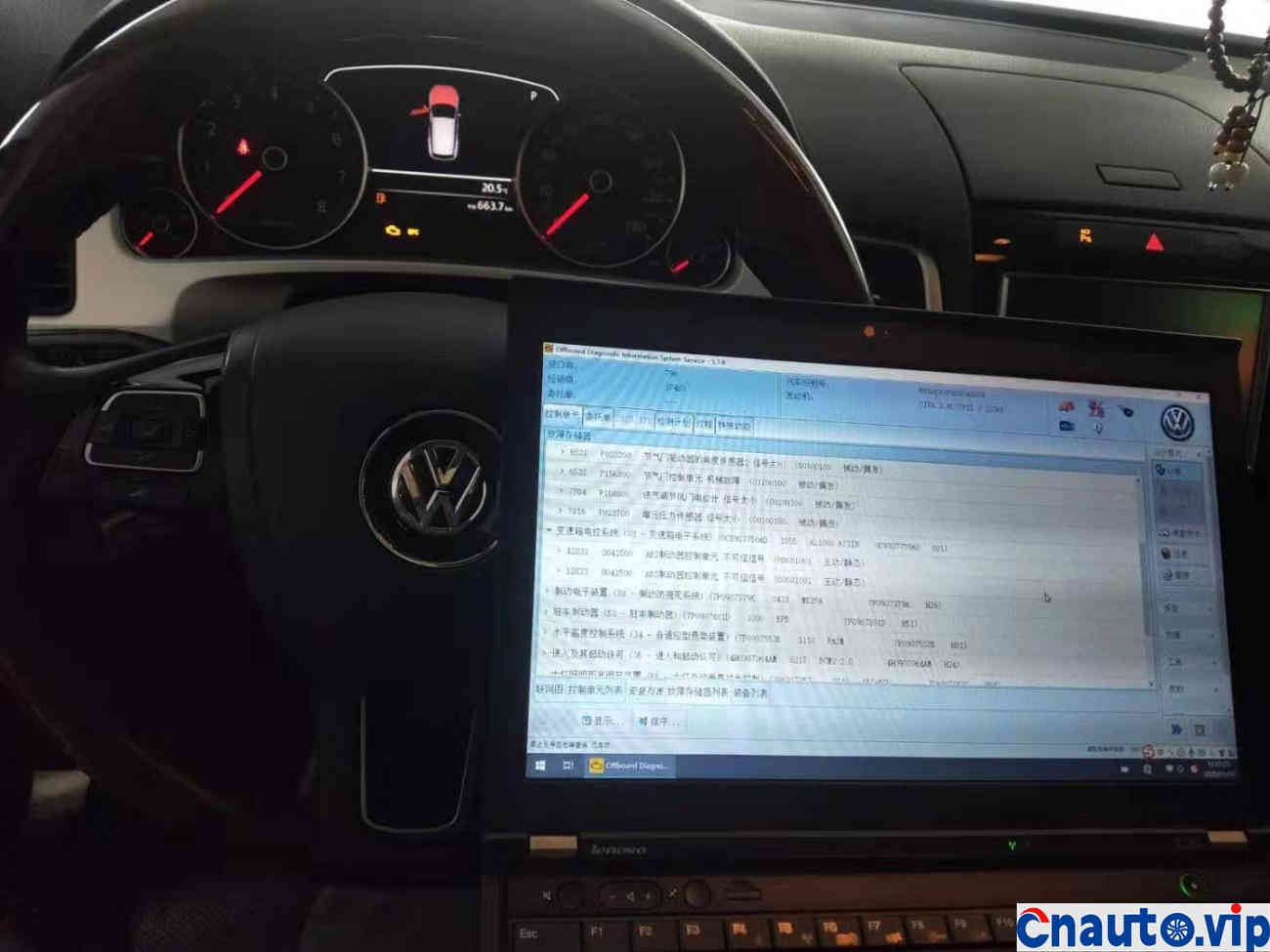

The vehicle goes to the store to read the fault code to see if there is any abnormal situation, to see if there is any relevant fault code to avoid rework.

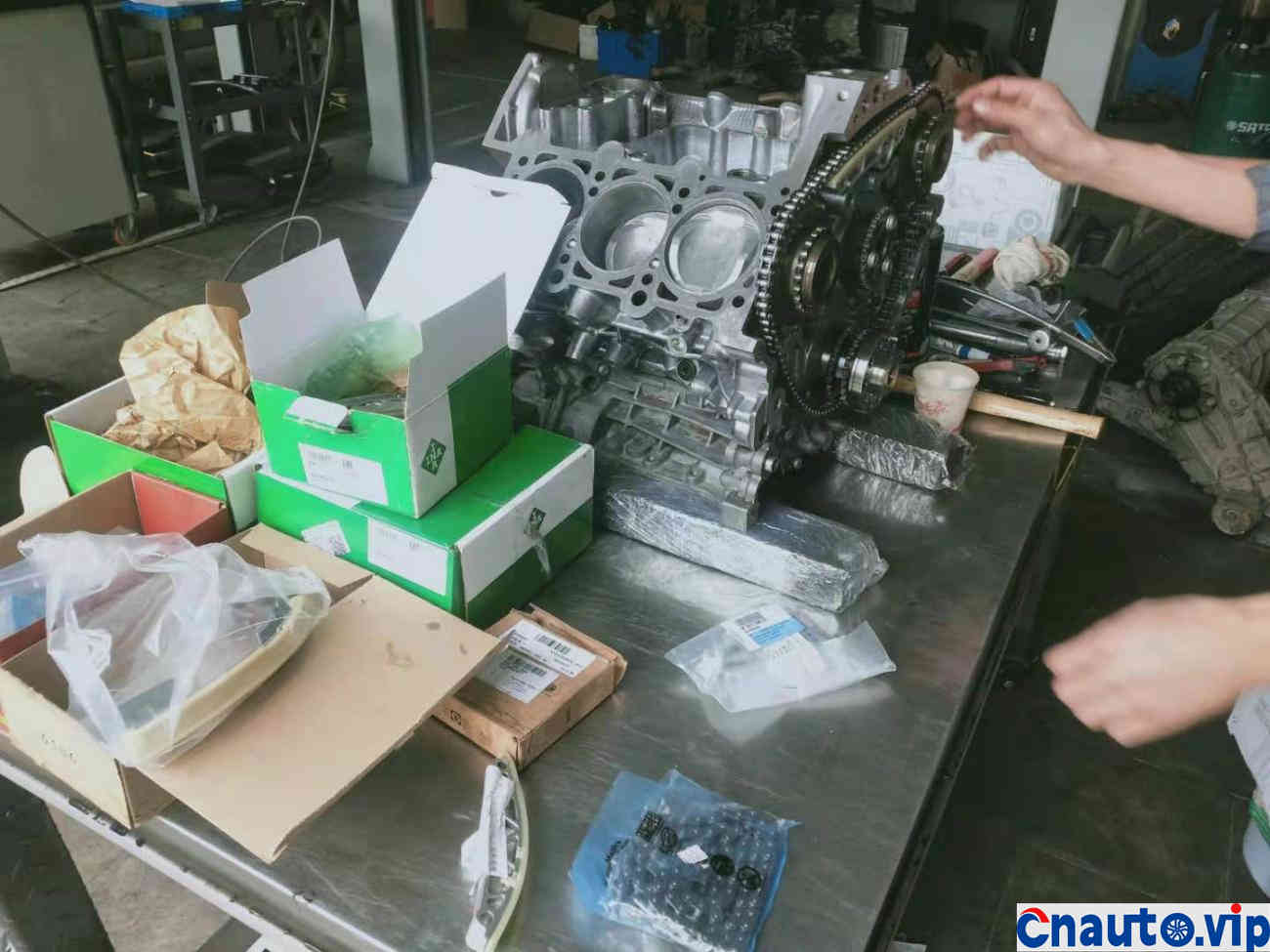

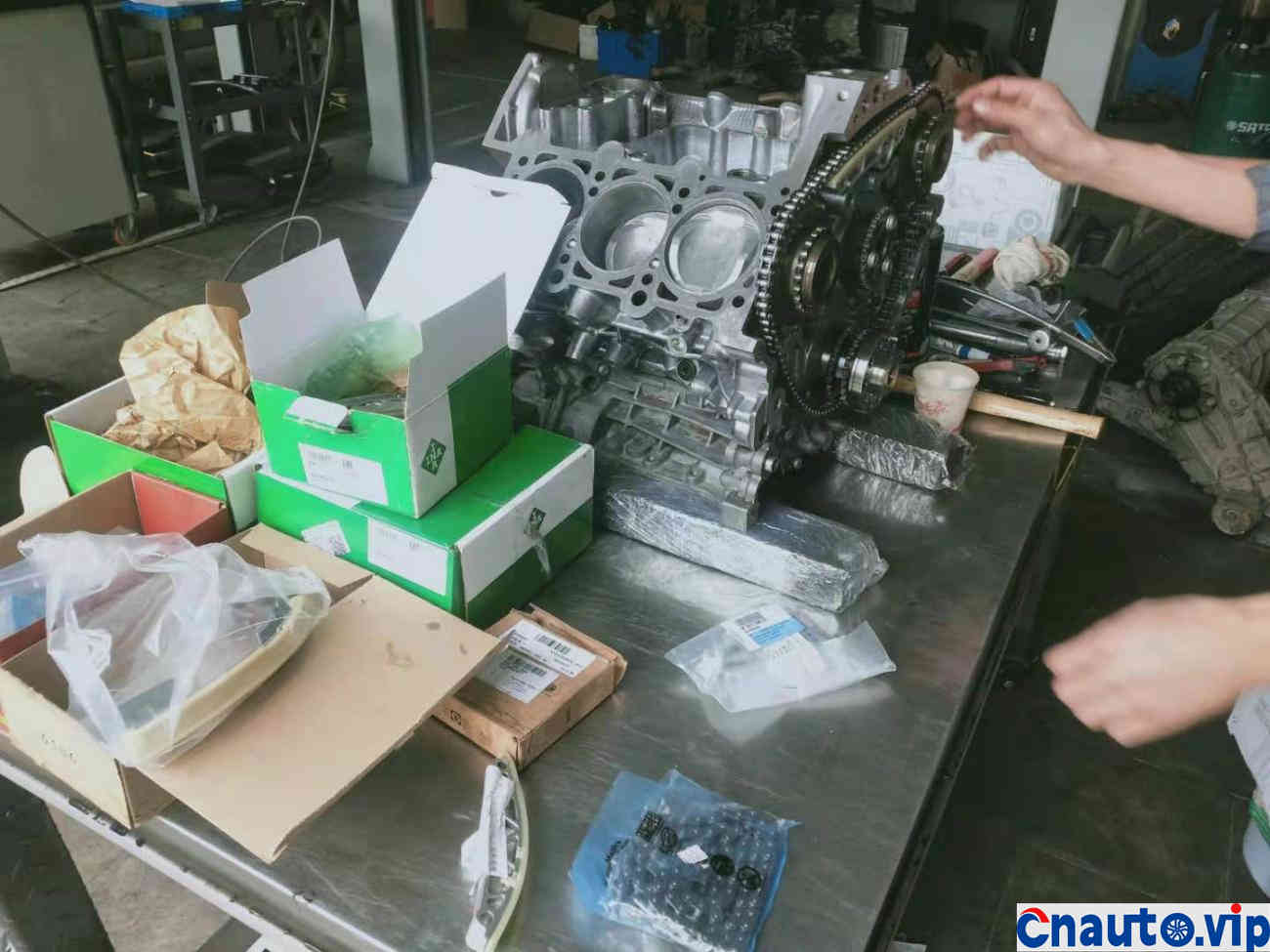

After hours of hard work, we unloaded the engine and were about to decompose it. Record the parts that need to be replaced at the same time.

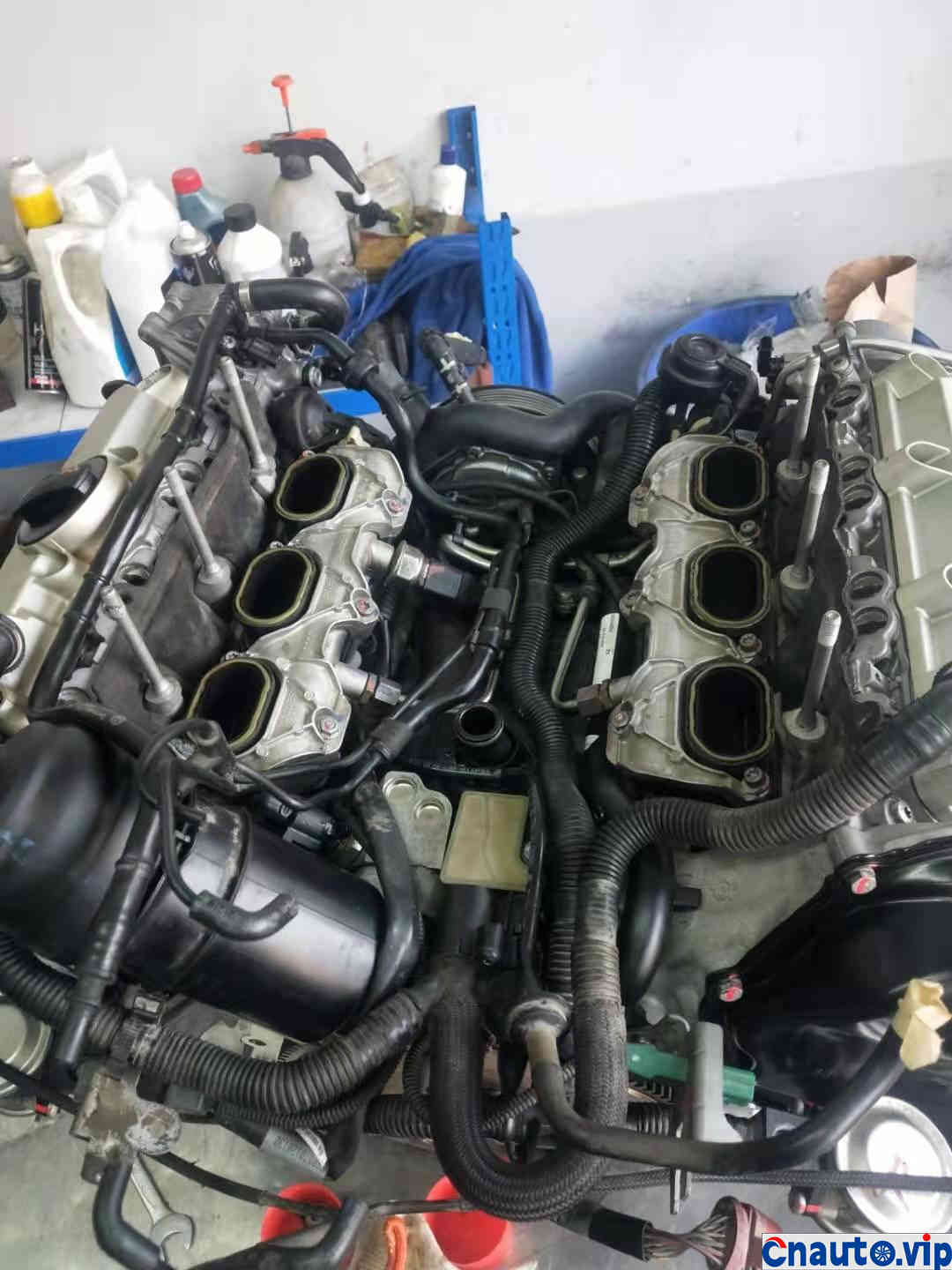

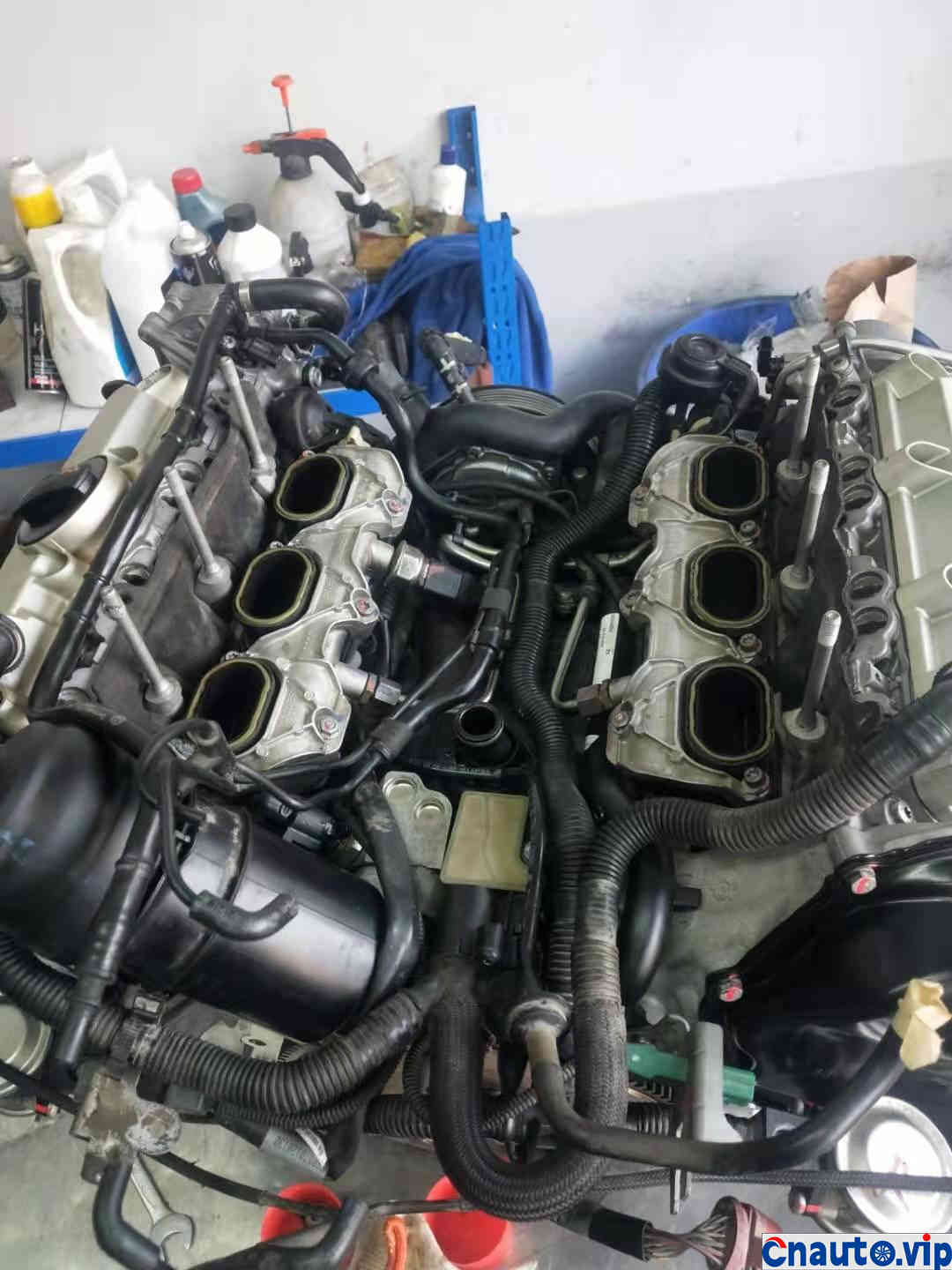

A shelf and an engine, a total of two Touareg overhauled, one mixed with a pure oil.

The disassembled piston looks very serious.

Take a positive one. Carbon deposits need to be cleaned regularly to avoid pulling cylinders.

If you don’t come and take a picture of the piston ring, you can probably see the video screenshot clearly. I don’t know how long the piston ring designed by the awesome person will last. Take a look. Try to replace the improved piston ring at the request of the guest.

The valve needs to be re-ground, after all, more than one hundred thousand kilometers, the contact surface will inevitably have ablation points, through grinding can greatly improve tightness.

After the valve grinding, the old way to test whether the valve grinding is defective, (very good)

Clean the piston to measure wear and tear to see if it needs to be replaced.

After measuring the diameter of the skirt, we found that the replacement condition was not reached, and the piston assembly could not be replaced.

Valve oil seal must use regular parts, if the rubber material is not good for a long time burning oil will still have.

Measure the diameter clearance to see the wear limit. Boring the cylinder is really not recommended if it can not be bored.

Touareg is waiting for the assembled engine, and the S400 next to it will be changed to pure fuel simultaneously.

You need to do enough preparation before assembling the engine, you need to measure the clearance of the bearing bush, and when the preparation work is done, just install it.

Checking bearing clearance requires some instruments such as micrometer, expensive clearance, torque wrench and so on.

The contrast of the bearing clearance is good, not to the point that it needs to be replaced.

Each bearing needs to be measured.

The large tile rack needs to be smeared with gasket-free sealant during installation. Resistant to high temperature of 300 degrees.

Each screw is tightened according to the maintenance manual, and the bolts that need to be replaced are replaced in time.

Attention should be paid to the control of force and torque

12 brand new bolts

Can you see the difference between the old and the new.

Tighten torque and angle according to standard.

The lower contact surface of this engine is gasket-free and can be applied with sealant.

The assembly of the lower part of the engine is basically completed.

When some EA837 engines leave the factory without oil check valves, two check valves are required for maintenance. I don’t know what I think.

We replace the parts in addition to the original factory is a big brand matching, piston ring is an exception.

The repaired engine will guarantee you 60,000 kilometers in 2 years.

Check the cylinder head and the surface of the rigid body for deformation.

There is no harm in measuring a few more places to avoid oil and water leakage

To install the cylinder head, there are also conditions that require the use of power tools, different angles and different forces.

Install camshaft and rocker arm

The camshaft bracket as a whole needs to be paid attention to.

Tighten the bolts in order.

Installing the oil seal in front of the crankshaft requires a small skill, which is convenient and fast.

The front installation is followed by the rear end cover.

Install the front and check while waiting for the accessories.

Two brand new camshaft end caps.

Install the mechanical supercharger.

Install the wiring harness and motor of the engine

Then install the accessories of the engine, which are equivalent to human blood vessels and nerves, so as to ensure that the engine runs well and detect the engine’s every move at any time.

Transmission link bolts disposable aluminum alloy bolts, replacement of a new set of bolts is not much expensive, but can ensure that the strength of the link is enough.

Tighten the engine foot bolts.

Replace a new set of NGK spark plugs.

The engine is about to be installed back into the car body.

Guess the displacement of the Gyibug next to it. Gearbox accessories are really hard to find.

Leave a souvenir.

The picture of the separation of the engine and the car body was put back a few days later.

Start the car smoothly, in-situ running-in for 4 hours, no oil leakage, no abnormal leakage, prepare for the road test.

After a few days of road test driving about 200 kilometers, there was no abnormal situation in the middle, and the vehicle was cleaned and handed over.

April 1, 2024

April 1, 2024