Mitsubishi Lancer rear pump disassembly and maintenance handbrake repair needle roller bearing replacement-assembly

Mitsubishi Lancer rear branch pump disassembly and maintenance handbrake maintenance needle roller bearing replacement-disassembly

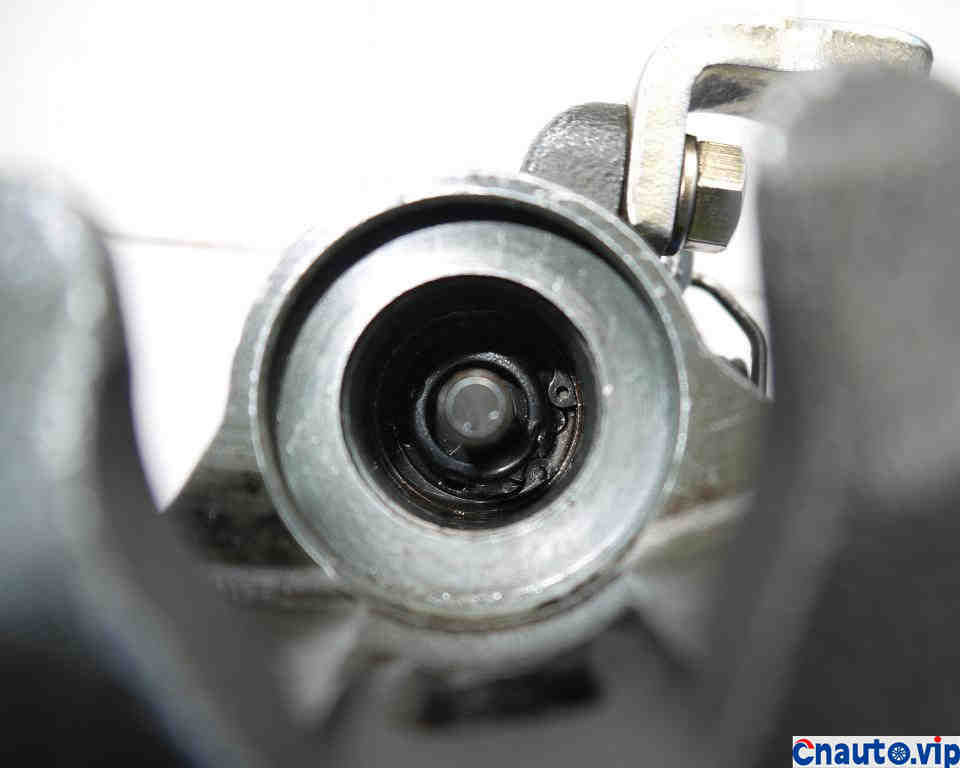

Apply lithium-based grease after pressing the needle bearing. The needle bearing size is 15.8*20.6*19 (unit: mm), put in the rotating shaft, and then from another hole, which is the hole where the piston is placed, throw the cylindrical pin in so that it just falls into the gap of the rotating shaft, rotate the rotating shaft so that the cylindrical pin extends the shortest, and then load it into the screw. The recommended specification for the screw sealing ring is 14mm* 2.0 mm with an outer diameter. Install the spring pressure plate, etc., and use circlip pliers to install the circlip (Specification 30 mm internal hole circlip) It is difficult to install with 6-inch circlip pliers and cannot go deep into the bottom. Unless it is a circlip pliers specially designed for extended deep holes, only the part blocked by the circlip pliers is polished off. Finally install the piston and sealing ring.

The repaired Mitsubishi Lancer rear brake, branch cylinder and hand brake

Press the bearing in using a G-clip

Use a strong and thin wire to tie the spring to the pressure plate to compress the spring so that the circlip can be installed over it

Place into hole

Install the circlip and unclip the wire and take it out

The piston seal ring oil seal has become bigger and can no longer be used.

Install the piston seal ring

Both brake cylinders have been repaired, and one of them has been loaded and used.

Tools used, including but not limited to

Hot Information

Tesla Autopilot and similar automated driving systems get ‘poor’ rating from prominent safety group

April 1, 2024

April 1, 2024 Localization of EV parts without production scalability may not help cut EV price, says President, Amara Raja

March 27, 2024

March 27, 2024

JCTSL may turn bus stands into charging points for e-buses

March 27, 2024

March 27, 2024 You May Like