-

Armed steel front gun steel pipes at Lingong 953 vehicles

Armed steel front gun steel pipes at Lingong 953 vehicles -

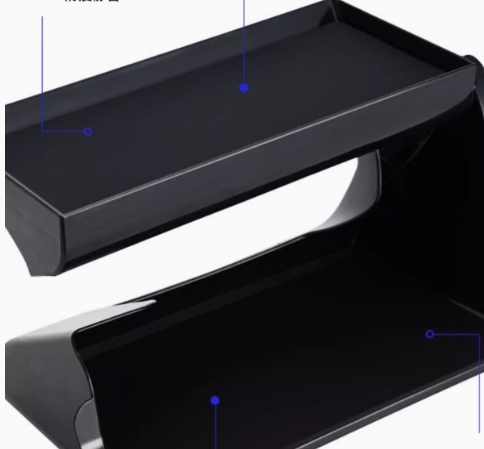

Be suitable for Tesla ModeL3Y special central control screen storage box, car storage box, car modification accessories and supplies

Be suitable for Tesla ModeL3Y special central control screen storage box, car storage box, car modification accessories and supplies -

Supporting device

Supporting device -

For 07-13 BMW 1 Series E82 Front Bumper Lip Splitter Spoiler Carbon Fiber Look

For 07-13 BMW 1 Series E82 Front Bumper Lip Splitter Spoiler Carbon Fiber Look -

For 2019-2022 BMW 3 Series G20 M-Tech Front Bumper Fog Lamp Sensor Hole NO ACC

For 2019-2022 BMW 3 Series G20 M-Tech Front Bumper Fog Lamp Sensor Hole NO ACC -

AC switch audio CD button knob cover trim compatible

AC switch audio CD button knob cover trim compatible

Q

who makes saab vehicles

I'm a seasoned industrial engineer with a keen interest in machine learning. Here to share insights on latest industry trends.

MachineLearningFactory: Bridging the gap between machine learning and industry applications.

You May Like

To rev an engine from the engine bay, one method involves manually manipulating the throttle. It's important to note that this procedure may vary slightly depending on the specific vehicle's design. Typically, on a fuel-injected engine, you'll find the throttle body attached to the air intake manifold. Locate the throttle linkage or cable which is usually connected to a lever on the throttle body. By gently pushing or pulling this lever, you can manually open the throttle valve, allowing more air to enter the engine, which in turn increases the RPMs. For carbureted engines, a similar lever or linkage can be found on the carburetor itself for the same purpose. Always ensure the vehicle is in "Park" or "Neutral" and exercise caution to avoid contacting moving parts or hot surfaces. This method is commonly used for maintenance checks, troubleshooting, or performance tuning. Remember, running the engine at high RPMs without a load (as when the vehicle is stationary) can sometimes cause damage or excessive wear, so keep the revving brief and infrequent.

Diesel engine runaway occurs when the engine starts burning its own oil or external hydrocarbons at uncontrollable rates, leading to potentially catastrophic outcomes. This phenomenon is often due to oil getting into the combustion chamber, which the engine then uses as fuel, causing uncontrollable acceleration.

To stop a diesel engine runaway, the key is to cut off the air supply, as diesel engines require air for combustion. This can be done in several ways, depending on your immediate resources and the engine's design:

1. **Use the engine's emergency stop mechanism** if fitted. Modern engines often include a specific feature designed to shut down the engine immediately in cases of runaway.

2. **Block the air intake manually**, but safely. Placing a solid object over the air intake can starve the engine of oxygen, thereby stopping the combustion process. This must be done carefully to avoid injury or damage.

3. **Activate the air shut-off valve**, if the engine is equipped with one. Some diesel engines are fitted with air intake shutoff valves specifically for this purpose.

It is crucial, for safety reasons, not to attempt to turn off the engine using the ignition or by engaging the vehicle in gear if it's moving. These methods are not effective during a runaway situation and can cause further damage or risk of injury. Regular maintenance and inspections can help prevent conditions leading to runaway, such as ensuring that the turbocharger is in good working order and that seals are intact to prevent oil from leaking into the combustion chamber. Safety training and awareness for operators are also paramount to manage such emergencies effectively.

Yes, a cracked engine block can be repaired, but the success and advisability of such repairs depend on the severity and location of the crack. Minor cracks can often be fixed using techniques like metal stitching or cold metal stitching, where special locks and seals are used to mend the crack without dismantling the engine. Welding, another solution, requires high skill levels to ensure the integrity of the repair and is typically used for larger cracks. However, both methods demand considerable expertise and can be costly. In some cases, especially when dealing with high-performance engines or where the crack compromises structural integrity significantly, replacement may be a more cost-effective and reliable option. It’s crucial to consult with a professional to assess the damage accurately and consider the engine's value and the cost of repair versus replacement before making a decision.

You May Like

Q&A

- •what is v6 engine means

- •what does a flashing service engine light mean

- •how to warm up car engine

- •does valvoline check engine light for free

- •how to tell what size engine you have

Popular Information

- •Automakers score victory as Energy Department weakens EV mileage rule

- •Stellantis to cut 400 engineering, technology jobs

- •Tesla Autopilot and similar automated driving systems get ‘poor’ rating from prominent safety group

- •JCTSL may turn bus stands into charging points for e-buses

- •Volkswagen, Mobileye expand autonomous driving collaboration