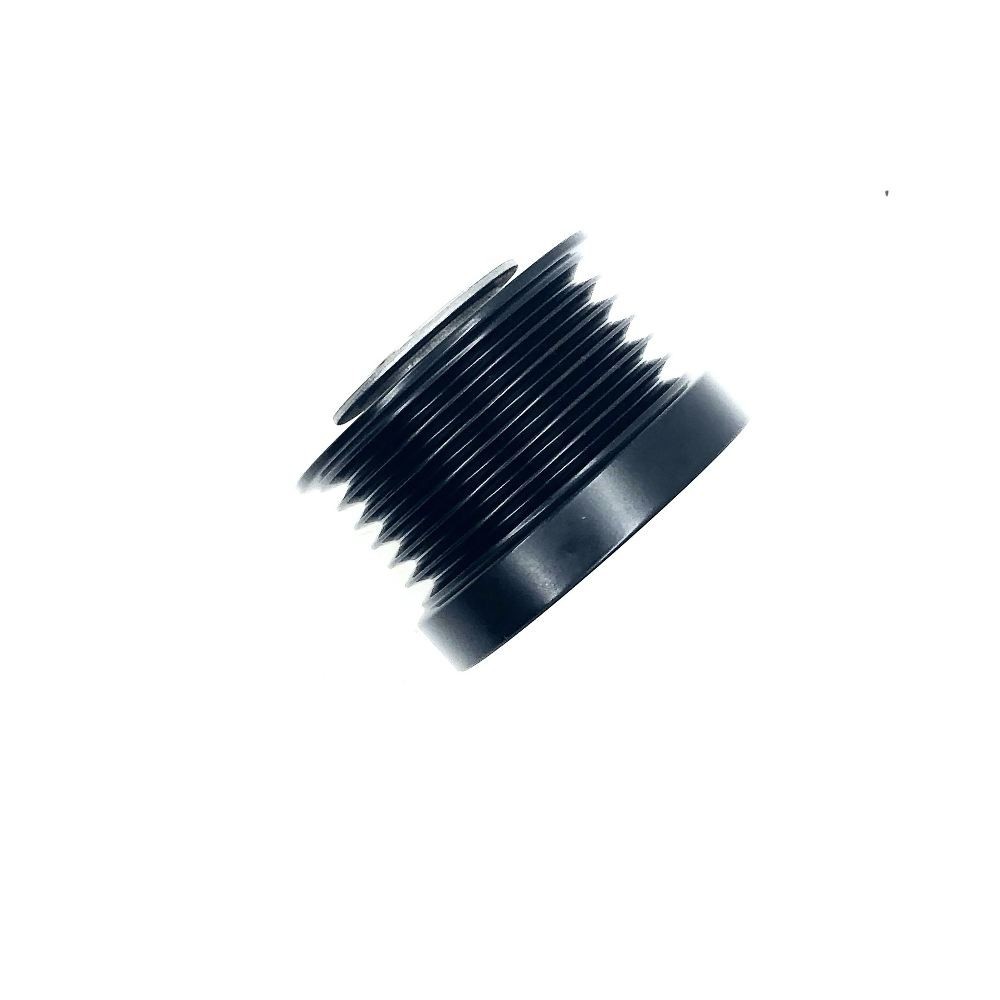

Shandongzhongchanggongchengjixieyouxiangongsi

Manufacturer/Factory

CN Supplier

4 YRS

Main Products:

建筑工程机械配件销售

Established:

2021-10-11

Company Size:

20人