Car seat belts are safety devices designed to restrain the occupants during a collision and to prevent secondary collisions between the occupants and the steering wheel and instrument panel, or to prevent the occupants from rushing out of the car during a collision, resulting in death or injury. Car seat belts, also known as seat belts, are a type of passenger restraint device. Car seat belts are recognized as the cheapest and most effective safety devices. Among vehicle equipment, seat belts are mandatory in many countries.

Origin #

Seat belts existed before the invention of automobiles. In 1885, when horse-drawn carriages were commonly used in Europe, seat belts were simply used to prevent passengers from falling off the carriage. By 1910, seat belts began to appear on airplanes. In 1922, sports cars on the racing circuit began to use seat belts. By 1955, Ford cars in the United States began to use seat belts. Generally speaking, the seat belts during this period were mainly two-point seat belts. In 1955, aircraft designer Niels invented the three-point safety belt after working for Volvo Car Company. In 1963, Volvo Car Company began to register Niels’ three-point car seat belt and assemble it on its own cars. In 1968, the United States stipulated that all forward-facing seats in cars must be equipped with seat belts. Developed countries such as Europe and Japan have also successively formulated regulations requiring car occupants to wear seat belts.

Structure #

1. Webbing Webbing is a belt about 50mm wide and 1.2mm thick made of synthetic fibers such as nylon or polyester. Depending on the purpose, the strength, elongation, etc. required by the safety belt can be achieved through weaving methods and heat treatment. characteristic. It is also the part that absorbs conflicting energies. National regulations have different requirements for the performance of seat belts.

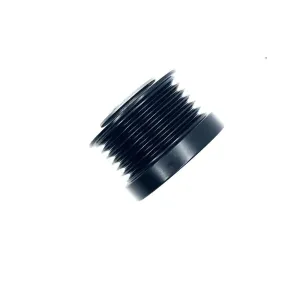

2. The retractor is a device that adjusts the length of the seat belt according to the occupant’s sitting posture, body shape, etc., and retracts the webbing when not in use. Divided into ELR and ALR.

3. Fixing mechanism The fixing mechanism includes buckles, lock tongues, fixing pins and fixing seats, etc. The buckle and tongue are the devices for fastening and unfastening the seat belt. The end of the webbing that is fixed to the body is called a fixing plate, the fixed end of the body is called a fixing seat, and the bolts used for fixing are called fixing bolts. The position of the shoulder safety belt fixing pin has a great impact on the convenience of fastening the safety belt. Therefore, in order to suit passengers of various sizes, an adjustable fixing mechanism is generally used to adjust the position of the shoulder safety belt up and down.

Principle #

The function of the retractor is to store the webbing and lock the webbing from being pulled out. It is the most complex mechanical part in the safety belt. Inside the retractor is a ratchet mechanism. Under normal circumstances, the occupants can freely pull the webbing on the seat at a constant speed. However, once the continuous pulling process of the webbing from the retractor stops or when the vehicle encounters an emergency, the ratchet mechanism will act. The locking action automatically locks the webbing and prevents the webbing from being pulled out. Installation fixings are lugs, plug-ins, bolts, etc. that are connected to the car body or seat components. Their installation position and firmness directly affect the protective effect of the seat belt and the comfort of the occupants.

Performance #

1. Seat belt design elements Seat belts should be designed to meet the requirements of occupant protection performance, reminder to use seat belts, as well as comfort and convenience. The design means to achieve the above points are the selection of the position of the seat belt adjuster, the specifications of the seat belt and the auxiliary devices used.

2. Occupant protection performance The requirements for the occupant protection performance of car seat belts are as follows: restrain the occupant as early as possible; minimize the pressure on the occupant when restraining; keep the restraint position unchanged so that the restraint force avoids the more vulnerable parts of the human body. As a means to achieve the above goals, the use of the pretensioner and force limiter described above significantly improves the performance in these aspects.

April 1, 2024

April 1, 2024