-

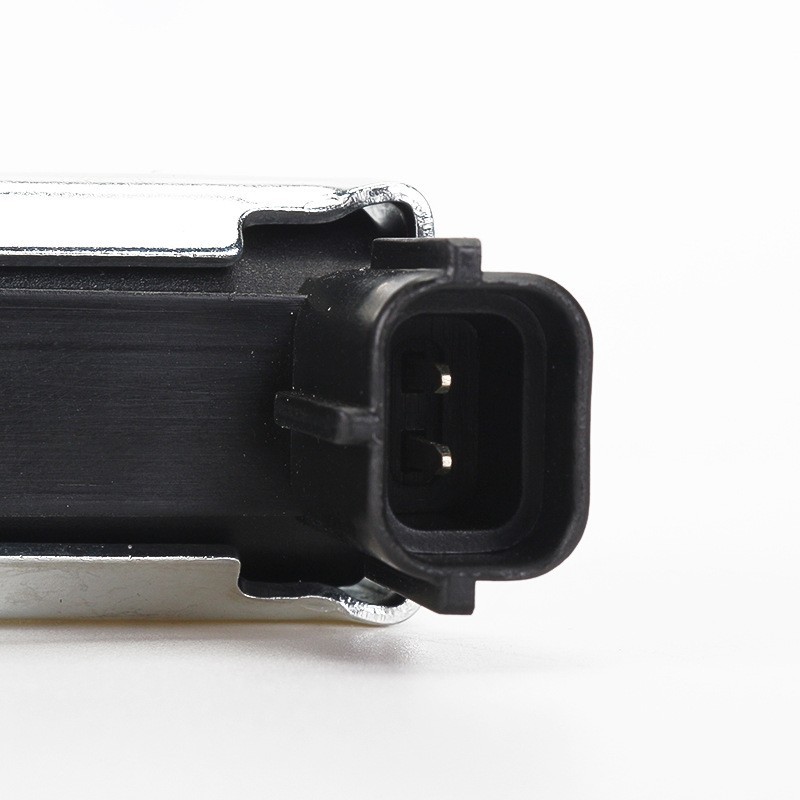

Control Motor, Auto Parts

Control Motor, Auto Parts -

Suitable for Tesla auto parts MODEL Y3 front cover engine cover 1493370-EC-A

Suitable for Tesla auto parts MODEL Y3 front cover engine cover 1493370-EC-A -

Suitable for BWM Rear Bumper Diffuser Lip

Suitable for BWM Rear Bumper Diffuser Lip -

Suitable for RAV4 Front and rear corner protectors body decorative strips

Suitable for RAV4 Front and rear corner protectors body decorative strips -

Suitable for Tesla Model 3 Hubcap 18 inch Fully Wrapped Rimcap Sport Hubcap Protector Accessories

Suitable for Tesla Model 3 Hubcap 18 inch Fully Wrapped Rimcap Sport Hubcap Protector Accessories -

Rear stabilizer bar - L/R Suitable for BMW 5 Series E60 (03-10)/E61

Rear stabilizer bar - L/R Suitable for BMW 5 Series E60 (03-10)/E61 -

Front and rear bumpers

Front and rear bumpers

Q

how much compression should a small engine have

I'm a seasoned industrial engineer with a keen interest in machine learning. Here to share insights on latest industry trends.

I'm a seasoned industrial engineer with a keen interest in machine learning. Here to share insights on latest industry trends.

You May Like

Generally, it's highly unlikely to pass a smog test if your check engine light (CEL) is on. The CEL is an indicator of emissions system issues that often direct towards malfunctioning components affecting your vehicle's exhaust cleanliness. In most jurisdictions, smog test procedures include an OBD-II inspection, where the vehicle's onboard diagnostics system is checked for emission-related fault codes. An illuminated CEL typically means there's at least one fault code that could directly relate to emissions failures. However, some temporary solutions, like resetting the light just before a test, rarely work due to readiness monitors that must be completed. Your best course of action is to address the underlying issue causing the CEL to illuminate. Repairing the problem not only increases your chances of passing the smog test but also contributes to environmental protection and optimizes your vehicle's performance.

Filling tractor tyres with water can provide additional weight and stability. It's usually done with about 75% water and 25% air in each tyre. It's essential to ask a professional or consult your tractor's manual if this process is appropriate for your model. Here is a simple step-by-step guide to do this:

Materials Needed:

1. Water source like a garden hose or water pump.

2. Large bucket or a barrel.

3. Liquid tubeless tire ballast or Tire Water Ballast Kit.

4. Water and antifreeze mixture (if you're in a very cold area)

Steps:

1. Park the tractor on a level ground.

2. Locate the valve stem on the tractor tire. It should be positioned at the top to prevent water from spewing out during the filling process.

3. Remove the valve core using a valve core removal tool. Now your tire should not have any air in it.

4. Connect a liquid tubeless tire fill kit to your tire's valve stem. These kits usually come with all hoses and nozzles required to inject liquid into a tire and they are mostly designed to connect to a standard garden hose.

5. Turn on the water source. If using a pump, make sure it's pumping water into the tire.

6. Fill the tire until the water reaches the valve stem. Remember, you still need to leave room for air.

7. Turn off the water source.

8. After filling with water, pressurize the tyre with air. Your owner's manual should have the correct PSI for your tyres. Be sure to follow these guidelines to prevent over-inflation.

9. Replace the valve core and tighten.

10. Repeat these steps for each tire you wish to fill.

Note: Antifreeze can be added to the water to prevent it from freezing in cold weather. Always check your tire pressure after filling them for several hours or the next day to ensure a good seal. Always remember safety first. If you're unsure, it's always best to have a professional do it for you.

Before attempting this operation. be aware of potential issues that may arise. The added weight of the tractor can put pressure on the axle or bearings. while cold temperatures can cause tires to explode if water freezes inside them. It is recommended to consult your tractor or tire manufacturer prior to proceeding with this task.

A 2-cycle diesel engine operates on the principle of completing a power cycle in just two strokes of the piston: combustion and compression. Unlike its 4-stroke counterpart, it lacks dedicated intake and exhaust strokes. Here's how it works:

1. **Compression Stroke**: As the piston moves up, it compresses the air in the cylinder, dramatically increasing its temperature.

2. **Power Stroke**: Just before the piston reaches the top, fuel is injected into the highly compressed air, causing spontaneous combustion due to the high temperature. The expanding gases from the combustion push the piston down. Near the bottom of the stroke, exhaust ports (and intake ports in some designs) are uncovered by the piston, allowing exhaust gases to escape and fresh air to enter, helped by a blower or turbocharger in most engines.

This design allows for continuous operation with power being generated every other stroke, making it very efficient in terms of size and weight to power output ratio. However, due to challenges like emissions control and efficiency at low speeds, 2-cycle diesel engines are predominantly found in applications requiring a high power-to-weight ratio, such as in large maritime engines, some generators, and specialized industrial applications. Their relatively simpler construction compared to 4-stroke engines can also result in reduced maintenance requirements but at the cost of increased fuel consumption and, typically, higher emissions.

You May Like

Q&A

- •what is an engine core

- •can onstar diagnose check engine light

- •how to mount an engine on a stand

- •what causes briggs and stratton engine to not start

- •how to start an inboard boat engine out of water

Popular Information

- •Tesla Autopilot and similar automated driving systems get ‘poor’ rating from prominent safety group

- •Stellantis to cut 400 engineering, technology jobs

- •Chinese battery giant CATL shrugs off EV sales slowdown to press on with expansion

- •JCTSL may turn bus stands into charging points for e-buses

- •Japan’s auto industry consolidates further with Honda, Nissan alliance