-

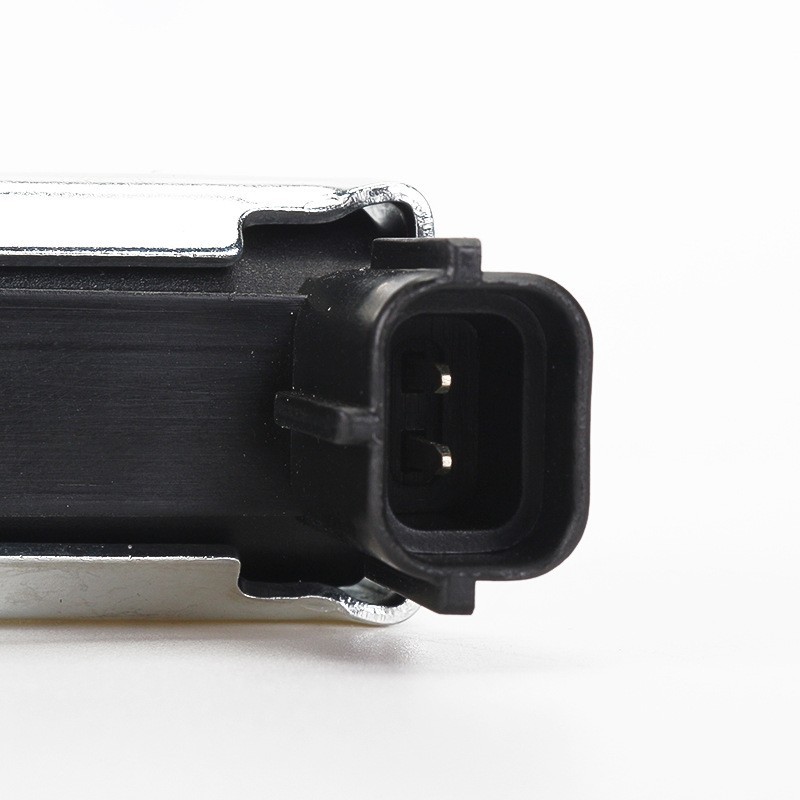

Control Motor, Auto Parts

Control Motor, Auto Parts -

Suitable for Tesla auto parts MODEL Y3 front cover engine cover 1493370-EC-A

Suitable for Tesla auto parts MODEL Y3 front cover engine cover 1493370-EC-A -

Front stabilizer bar - L Suitable for Mercedes Benz W221

Front stabilizer bar - L Suitable for Mercedes Benz W221 -

Upper swing arm - R Mercedes Benz W205

Upper swing arm - R Mercedes Benz W205 -

alternator pulley bearing for Peugeot 208, 308, 508, 2008, 3008

alternator pulley bearing for Peugeot 208, 308, 508, 2008, 3008 -

Upward Arm - R Audi A6L (C6)

Upward Arm - R Audi A6L (C6) -

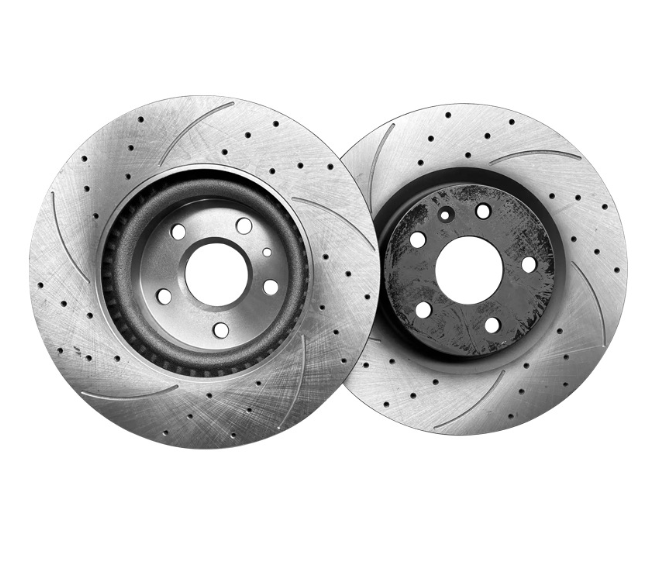

Suitable for Mercedes Benz brake discs GLK300 200 260 350 GLC260 300 GLC200

Suitable for Mercedes Benz brake discs GLK300 200 260 350 GLC260 300 GLC200

Q

can i pass inspection with check engine light

I'm a seasoned industrial engineer with a keen interest in machine learning. Here to share insights on latest industry trends.

I'm a seasoned industrial engineer with a keen interest in machine learning. Here to share insights on latest industry trends.

You May Like

Adjusting the governor on a Kohler engine is a precise process that helps maintain optimal engine speed and performance. First, ensure the engine is off and cool. Locate the governor arm and linkage. The governor arm is connected to the throttle and controls the engine speed. Loosen the bolt on the governor arm gently, so it can move freely. Push the governor arm so that the throttle is in the wide-open position, and simultaneously rotate the governor shaft in the same direction until it stops. While holding these positions, tighten the governor arm bolt securely. This calibration sets the internal governor to operate within the engine's designed speed range. Always refer to the Kohler engine manual specific to your model for detailed instructions and safety recommendations. Adjusting the governor improperly can lead to engine damage or personal injury, so if you're unsure, consult a professional. Regular maintenance and adjustments ensure your Kohler engine operates efficiently and lasts longer.

Low engine power can result from various issues, often linked to fuel delivery, air intake, or exhaust systems. Common causes include clogged air filters, which restrict airflow to the engine, fuel injectors delivering insufficient fuel, and malfunctioning sensors affecting the air-fuel mixture. Exhaust blockages can also impede engine output. Additionally, worn spark plugs or timing issues disrupt efficient combustion. Regular maintenance, including checking air filters, fuel injectors, and spark plugs, alongside diagnostic checks for sensor faults, can prevent these problems, ensuring your engine delivers optimal power. Identifying and addressing the specific cause is crucial for restoring engine performance.

To clean a carburetor on a small engine, first ensure the engine is cool and detached from its power source. Remove the carburetor, noting the configuration for reassembly. Disassemble it, keeping track of all parts. Use carburetor cleaner to spray all components, focusing on jets and passages. Stubborn deposits may necessitate a soft brush but avoid damaging sensitive parts. Rinse with cleaner and allow to dry completely. Reassemble carefully, replacing any worn gaskets or o-rings to prevent air leaks. Finally, reattach the carburetor to the engine, ensuring a snug fit. This process improves engine performance by ensuring a proper fuel-air mixture, essential for smooth operation. Always consult the engine's manual for specific instructions and safety precautions.

You May Like

Q&A

- •what is the best k24 engine

- •is the gm 3.6 l an interference engine

- •is the ecotec3 5.3l v8 a good engine

- •is the n63 engine reliable

- •can a bad ac compressor cause check engine light

Popular Information

- •Tesla Autopilot and similar automated driving systems get ‘poor’ rating from prominent safety group

- •Hyundai to reduce network partners as part of “future proofing” plan

- •Stellantis to cut 400 engineering, technology jobs

- •Xpeng, BYD executives say Greater Bay Area firms’ expertise in smart tech, superfast battery charging will drive EV growth in China

- •First drive: BMW iX2 becomes the coupe-SUV it was always meant to be