-

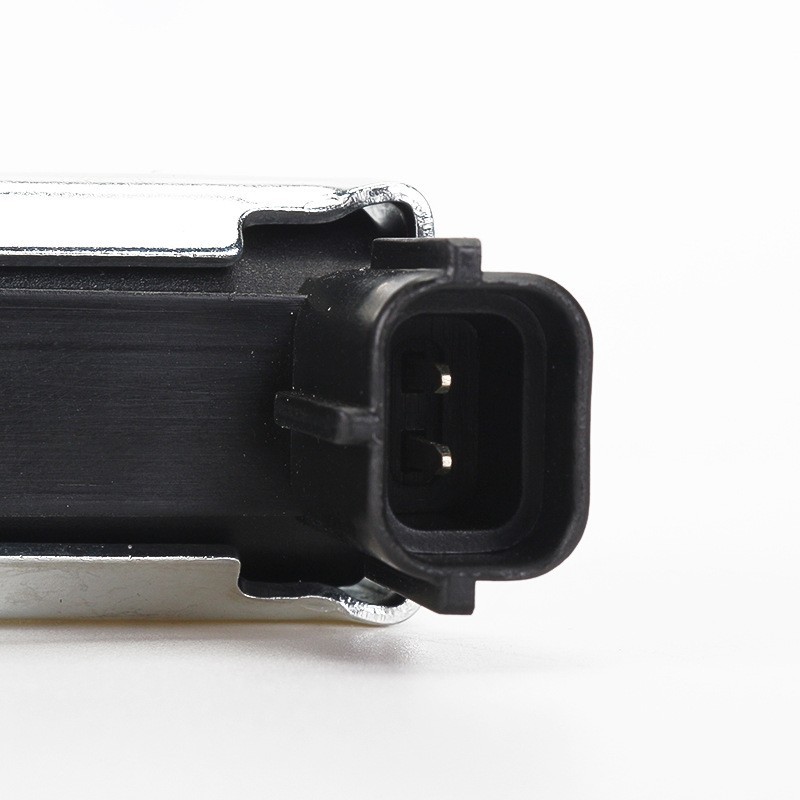

Control Motor, Auto Parts

Control Motor, Auto Parts -

Suitable for Tesla auto parts MODEL Y3 front cover engine cover 1493370-EC-A

Suitable for Tesla auto parts MODEL Y3 front cover engine cover 1493370-EC-A -

Suitable for BMW 5 Series F10 Car Center Console Air Vent Outlet Cover Trims

Suitable for BMW 5 Series F10 Car Center Console Air Vent Outlet Cover Trims -

Front Lip Splitter Glossy Black Spoiler Fit BMW E90 LCI Standard Bumper 2009-12

Front Lip Splitter Glossy Black Spoiler Fit BMW E90 LCI Standard Bumper 2009-12 -

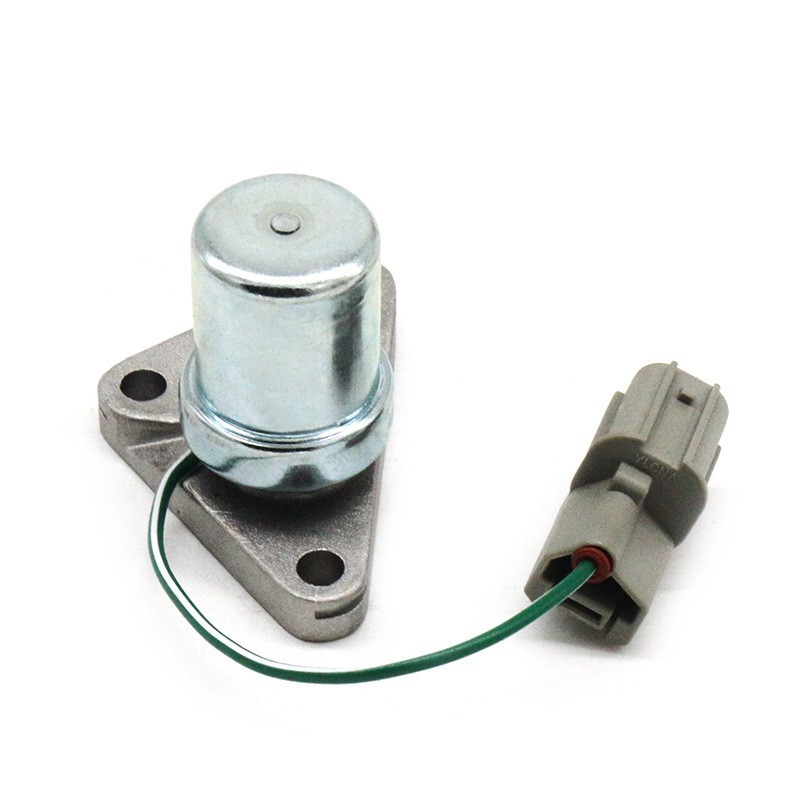

Solenoid valve assembly

Solenoid valve assembly -

Upper swing arm - L Mercedes Benz M-class (W164)

Upper swing arm - L Mercedes Benz M-class (W164) -

Peugeot 301 1.6L

Peugeot 301 1.6L

Q

does turning on heat cool engine

I'm a seasoned industrial engineer with a keen interest in machine learning. Here to share insights on latest industry trends.

I'm a seasoned industrial engineer with a keen interest in machine learning. Here to share insights on latest industry trends.

You May Like

Fuel mixing with engine oil in the crankcase, a condition known as fuel dilution, can occur for several reasons, primarily attributed to incomplete combustion. Causes include prolonged idling, where the engine does not reach optimal operating temperatures, leading to fuel not being fully combusted and thus seeping past piston rings into the crankcase. Additionally, a malfunctioning fuel injector can inject too much fuel, part of which bypasses the combustion process. This scenario is more common in vehicles with direct injection systems or those operating under cold start conditions frequently. Fuel dilution reduces the oil's viscosity, compromising its lubricating properties and potentially causing engine wear or damage. To prevent this, regular maintenance and addressing any malfunctioning components promptly are crucial. Ensuring the vehicle reaches and operates at its intended operating temperature during use can also mitigate this issue.

A car engine is intricately manufactured through a process that begins with the design and engineering phase, where precise specifications are established. Materials, primarily aluminum or cast iron for the engine block, are chosen for their balance of strength, weight, and thermal properties. The manufacturing process typically involves casting or forging the engine parts, followed by machining to achieve the precise dimensions and tolerances required for assembly. Components like pistons, crankshafts, and connecting rods are carefully crafted and tested for durability and performance. Advanced computer-controlled equipment and skilled technicians work in tandem to assemble the parts, ensuring tight seals and proper alignment. Throughout the process, rigorous quality control measures are in place to guarantee the engine meets strict performance and emission standards. The result is a powerful, efficient engine ready to power vehicles reliably. This intricate process underscores the blend of engineering prowess and manufacturing precision essential in producing car engines today.

Nearly all electric vehicles (EVs) available today come equipped with automatic transmissions, and for good reason. The essence of an electric vehicle's powertrain operates differently from that of internal combustion engine vehicles. An electric motor provides instantaneous torque, offering a smooth acceleration curve from a standstill. This characteristic removes the need for manual gear shifting to modulate power, as is necessary in traditional gasoline or diesel vehicles. Moreover, the design of electric motors allows for precise control over vehicle speed and acceleration with a single gear, making the concept of a multi-speed transmission largely redundant. As such, designers and engineers opt for automatic transmissions to simplify the drivetrain, enhance efficiency, and improve the driving experience. While there may be exceptions on a conceptual or experimental level, the overwhelming majority of commercial EVs feature an automatic transmission setup for these practical and performance-oriented reasons.

A typical electric car does not come with a manual transmission like a gasoline-powered car. Electric cars use electric motors instead of internal combustion engines to drive the wheels. so manual transmissions are obsolete. Since there is normally only one gear. drivers do not have to change gears. Rather. they use a simple forward-neutral-reverse system.

You May Like

Q&A

- •330 pace bus

- •does dollar general sell engine coolant

- •does disconnecting the battery reset check engine light

- •best tyres brand

- •is the gmc 2.7 turbo a good engine

Popular Information

- •Chinese battery giant CATL shrugs off EV sales slowdown to press on with expansion

- •Hyundai to reduce network partners as part of “future proofing” plan

- •GKN Automotive to shutter North Carolina facility

- •China to challenge Biden’s electric vehicle plans at the WTO

- •JCTSL may turn bus stands into charging points for e-buses